A glue dropper

A rubber dropper and dropper technology, applied in the field of experimental teaching, can solve the problems of broken rubber dropper, operation fatigue, high hardness, etc., and achieve the effect of convenient liquid taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

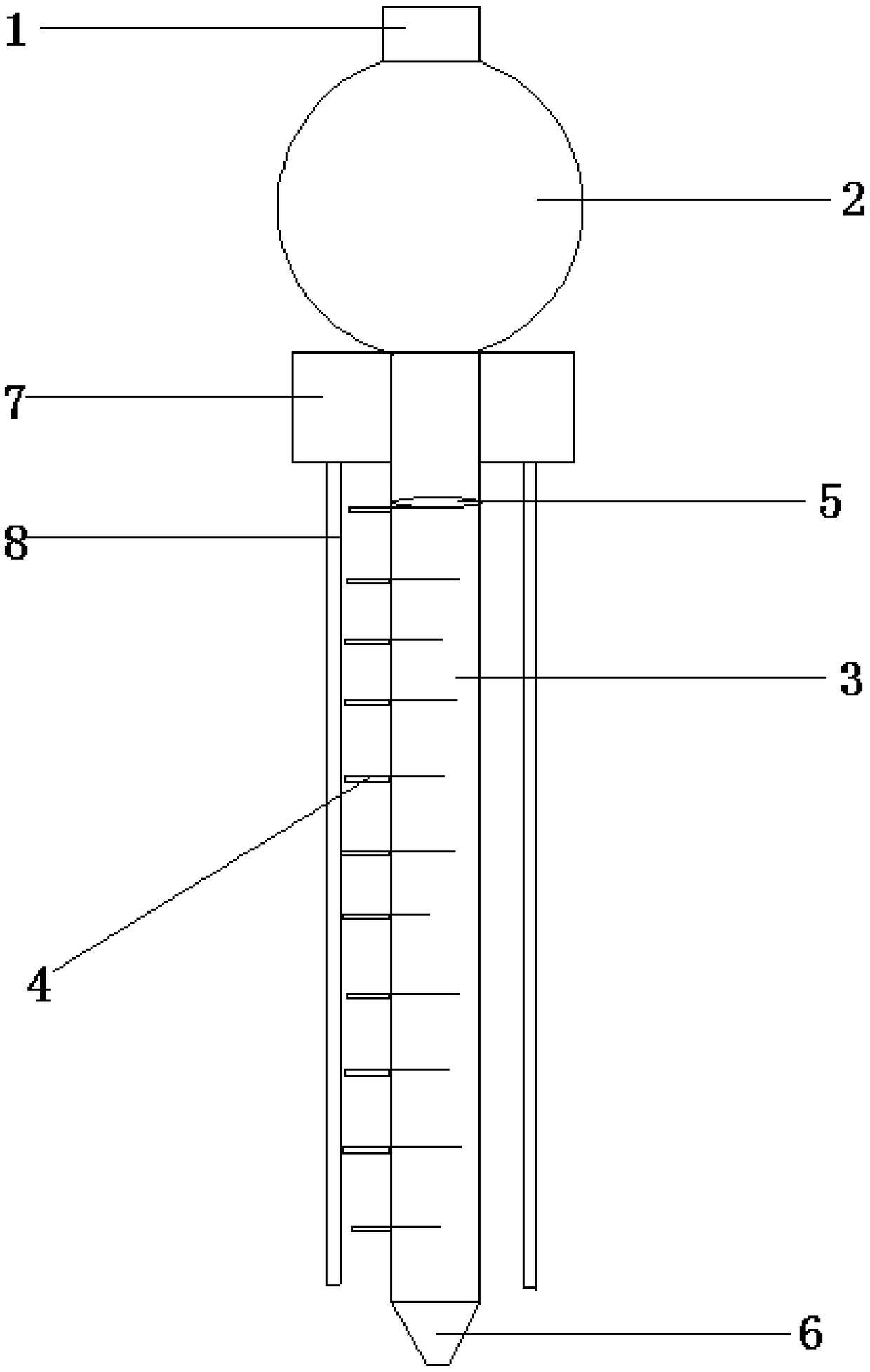

[0020] see figure 1 , in a preferred embodiment of the present invention, a glue head dropper, including a ferrule 1, a glue head 2, a dropper 3, a suction nozzle 6, a storage tank 7, a certain amount of cover 8 and A limit piston 5. The ferrule 1 is arranged on the top of the glue tip 2, and the ferrule 1 can be used to place the paper sheet indicating the reagent absorbed by the glue tip dropper, so that people can distinguish the used glue tip dropper and avoid confusion. The bottom of the glue head 2 is connected to one port of the dropper 3, and the other port of the dropper 3 is connected to the suction nozzle 6; the glue head 2, the dropper 3 and the suction nozzle 6 are connected in a line, which is beneficial to the absorption of the reagent. The dropper 3 is composed of two arc-shaped glass sheets and two elastic slide rails, the arc-shaped glass sheets and the elastic slide rails are arranged at intervals and connected sequentially to form a cylindrical dropper 3; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com