A water method treatment process of waste tire pyrolysis residue

A technology for waste tires and processing technology, which is applied in wet separation, chemical instruments and methods, solid separation, etc., and can solve the problems of inability to realize the output of waste tire pyrolysis residue and pyrolysis gas phase output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

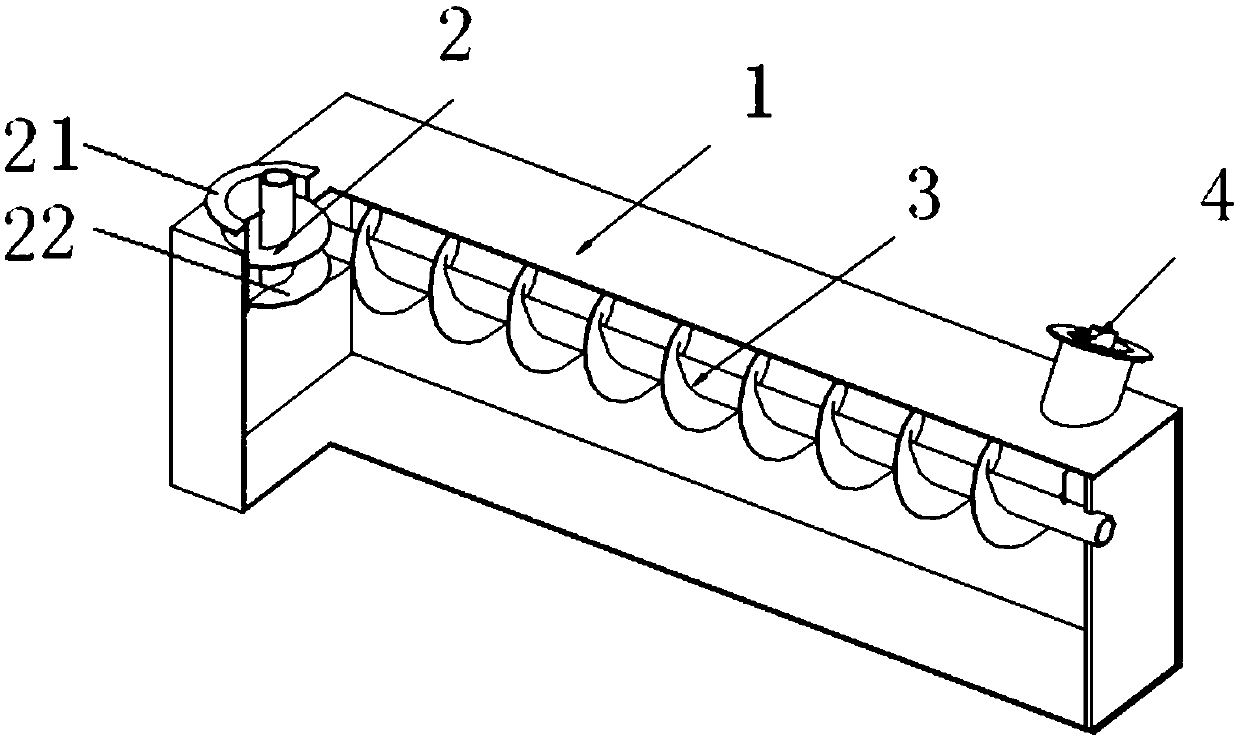

[0060] Such as figure 1 As shown, the waste tire cracking residue sealing conveying device in this embodiment includes a sealed box 1, and the inside of the sealed box 1 is filled with water (not shown in the figure).

[0061] The front end of the sealed box 1 is provided with a pressing screw 2 as a feeding mechanism, and the pressing screw 2 includes an outer sleeve 21 and blades 22 . One end of the outer sleeve 21 is fixed on the top of the sealed box 1, and the other end is connected to the discharge port of the cracking reaction device (not shown in the figure). The pressing screw 2 is driven by an external electric motor. Because the weight of waste tire pyrolysis residue is relatively light, in order to effectively press it into the sealed box, the rotating speed of the pressing screw 2 is greater than or equal to 30 rpm.

[0062] A discharge mechanism is provided at the tail end of the sealed box 1, that is, a screw mechanism 4 with a jacketed hydrophobic opening st...

Embodiment 2

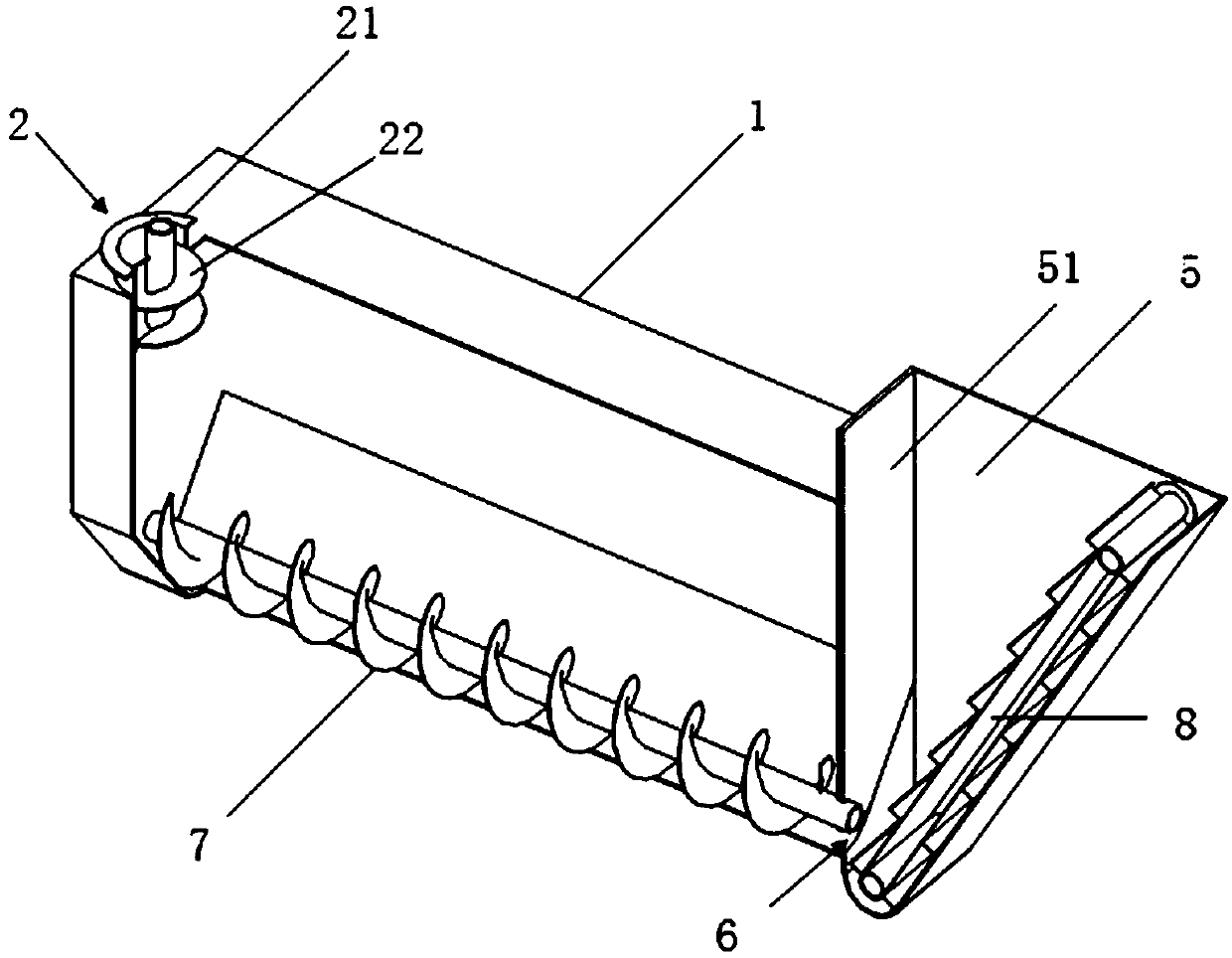

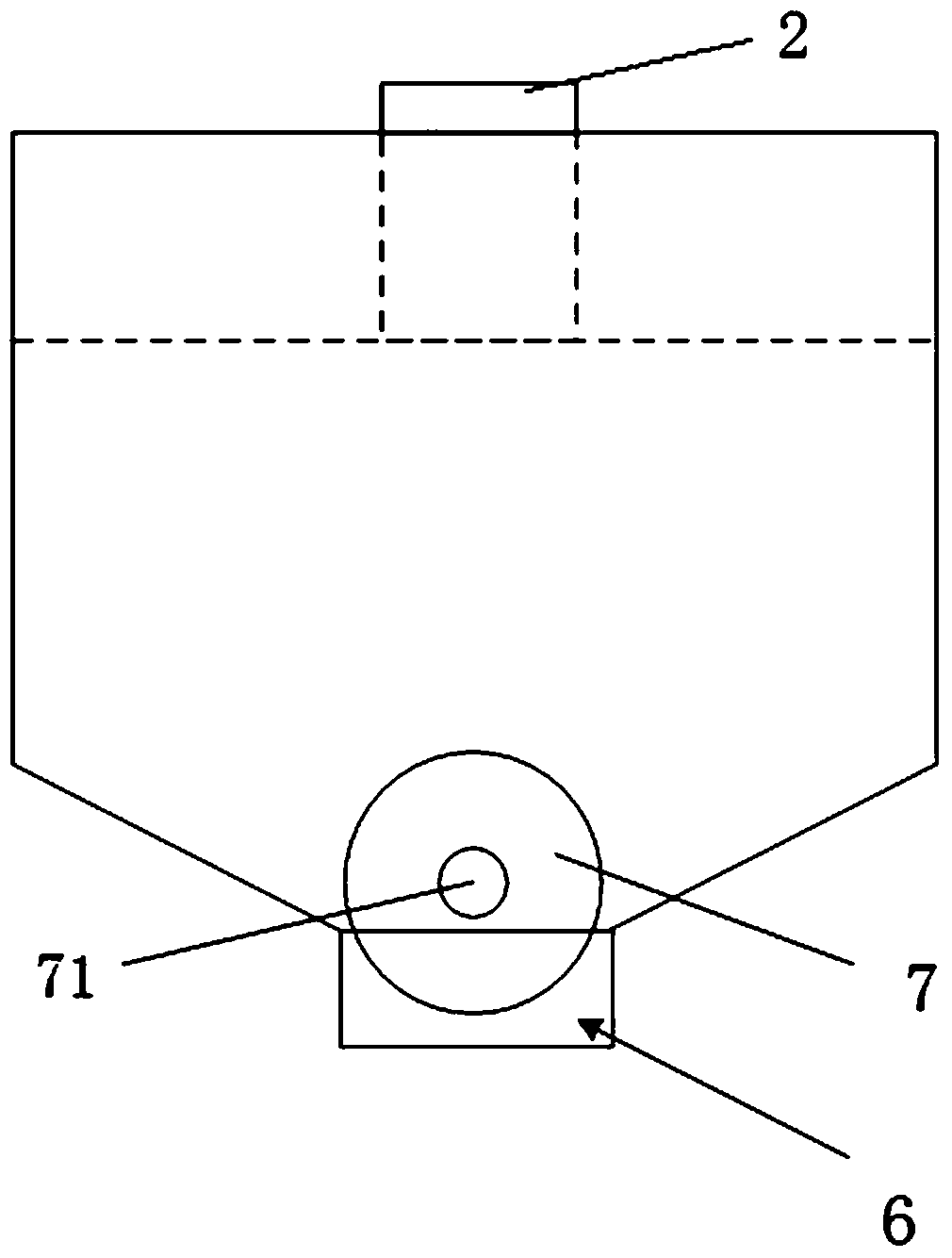

[0067] Such as figure 2 and 3 As shown, the water washing and sorting device for waste tire pyrolysis residue in this embodiment includes a sealed box 1, and a pressing screw 2 as a feeding mechanism is arranged on the top of the feeding side of the sealed box 1. The pressing screw 2 includes an outer sleeve 21 and blades 22 . One end of the outer sleeve 21 is fixed on the top of the sealed box 1, and the other end is connected to the discharge port of the cracking reaction device (not shown in the figure). A water isolation compartment 5 is provided on the discharge side of the sealed box 1 . The water isolation cabin 5 is adjacent to the sealing box 1, and the side plate on the discharge side of the sealing box 1 plays a role of separation, and isolates the water isolation cabin 5 from the upper part of the sealing box 1. A communication port 6 is provided at the bottom of the side plate 51 , so that the sealed box 1 and the water isolation compartment 5 become a communi...

Embodiment 3

[0074] Embodiments 1 and 2 jointly constitute the device used in the water treatment process of waste tire pyrolysis residues in Embodiment 3. For details, see Figure 4 , wherein the meanings indicated by the reference numerals are the same as those in Embodiments 1 and 2. The device is used to carry out the water treatment process of the present invention. The specific process is as follows:

[0075] The waste tire pyrolysis residue continuously output by the pyrolysis reaction equipment is conveyed to the feeding mechanism through the continuous conveying screw, pressurized by the speed of the pressing screw, and the waste tire pyrolysis residue is forced into more than 1L of water in the form of forced pressing. A sealed box, wherein the rotating speed of the pressing screw is 30 rpm. After the waste tire pyrolysis residue enters the airtight water tank full of water, it is cooled under the action of water. At this time, the stirring and propulsion mechanism under the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com