A composite thinning and deep drawing tooling

A tooling and die technology, applied in the field of stamping processing, can solve problems such as poor quality assurance capability and complex working procedures, and achieve the effects of reliable quality, improved product accuracy, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

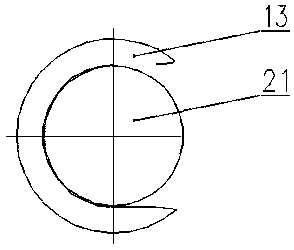

[0025] figure 1 It is the prior art thinning and deep drawing process. The cake product (cake state) is made into a barrel shape by ordinary deep drawing, and then the ordinary deep drawing surface is strongly squeezed and drawn by thinning and deep drawing. The deep surface is obviously thinner, thus showing a mirror effect, so as to meet the quality requirements of the product.

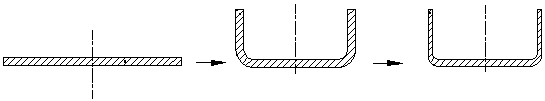

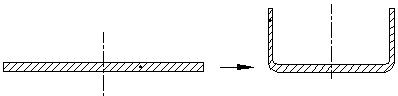

[0026] figure 2 In the composite drawing process of the composite thinning and drawing tooling of the present invention, the product (cake state) directly adopts the composite thinning and drawing, which reduces one process and improves efficiency. At the same time, because two deep drawing uses one positioning, the positioning accuracy is improved and the product quality is improved.

[0027] image 3 Among them, the equipment slider 1 is equipped with an upper template 3, the upper template 3 is equipped with an upper backing plate 5, and the upper backing plate 5 is equipped with a punch 6. They are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com