Full-automatic necking-in device for high lock nut

A technology of high locking nut and closing device, which is applied in the field of mechanical parts processing, can solve the problems of low processing accuracy and yield, prone to cracking, complicated operation, etc., and achieves the effects of high production efficiency, small instantaneous deformation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

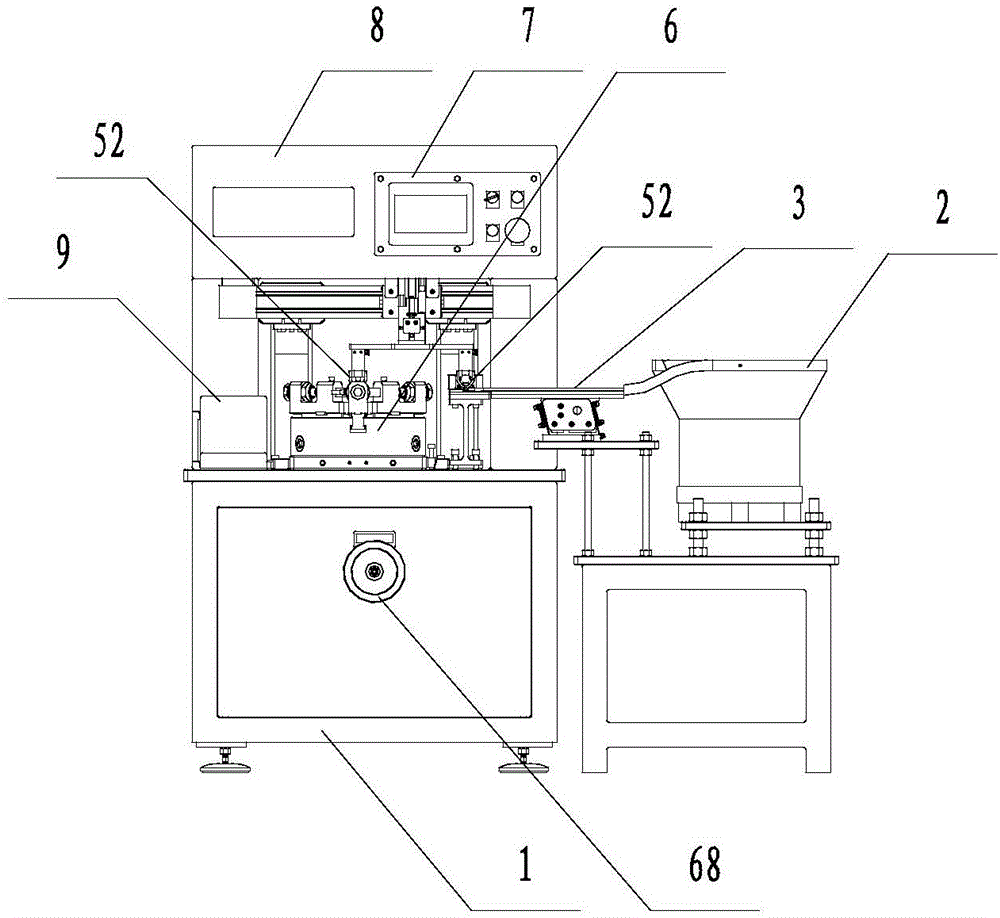

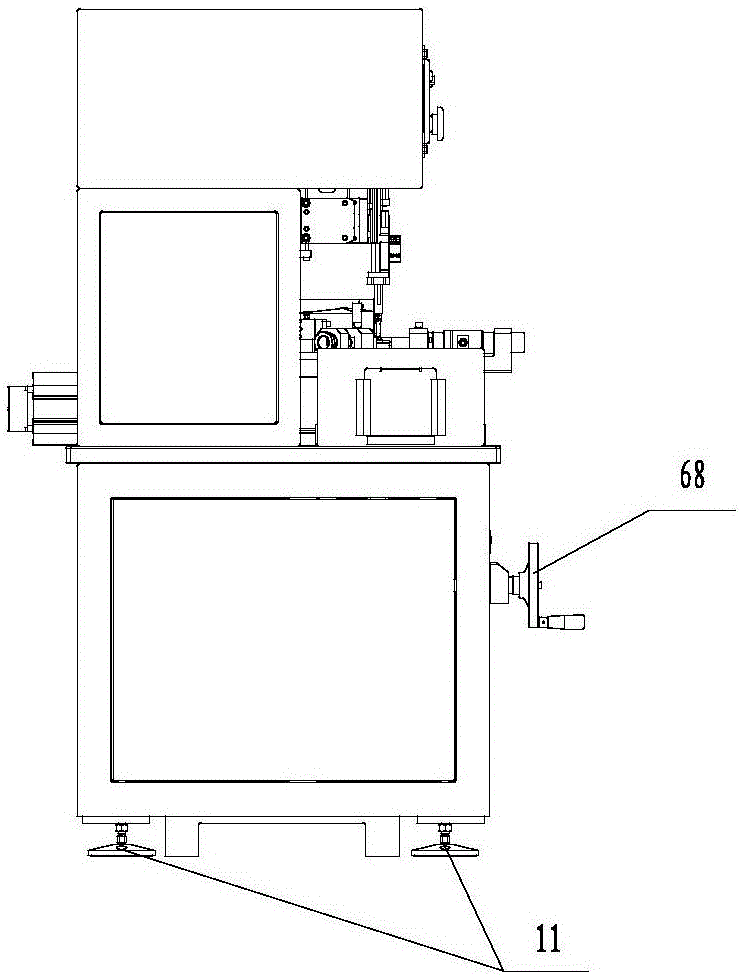

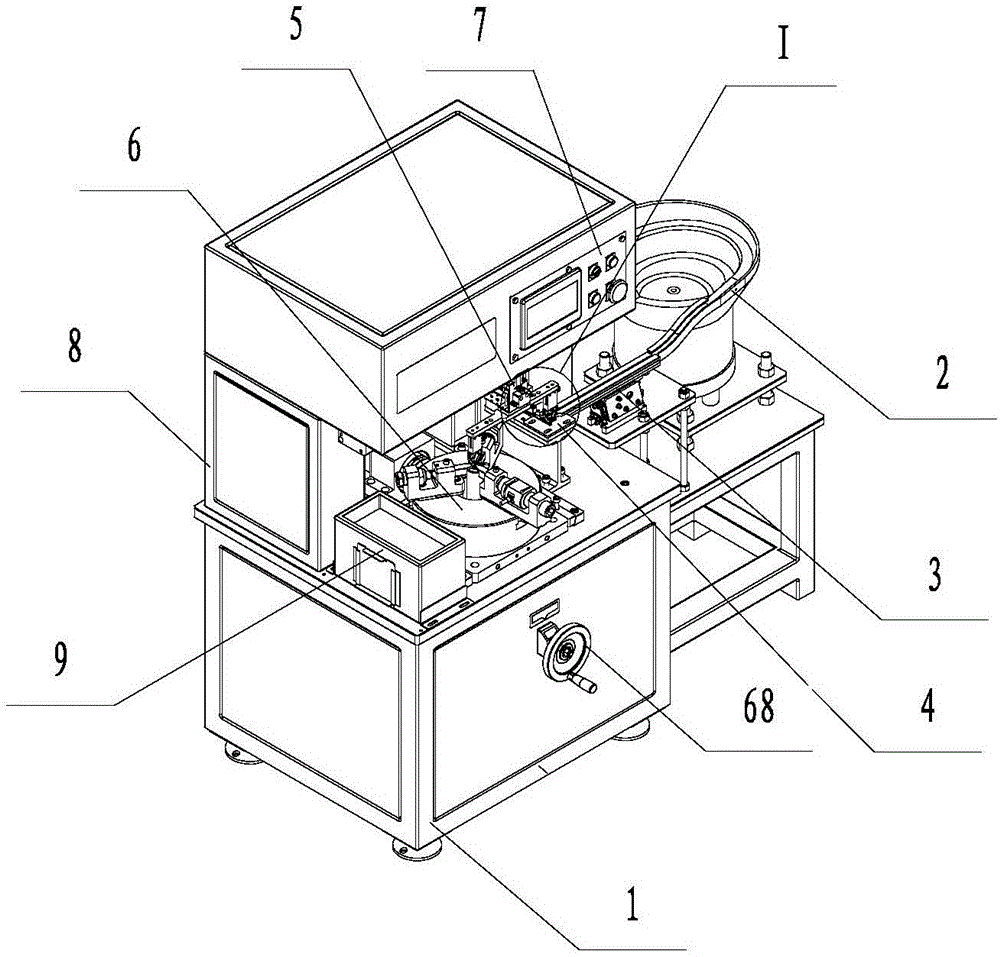

[0019] combine Figure 1~5 To illustrate this embodiment, a high-lock nut automatic closing device mainly consists of a frame 1, a vibrating plate 2, a direct vibrator 3, a blocking and separating mechanism 4, a station manipulator 5, Closing functional part 6, control box 7, electrical box 8 and material receiving box 9 are formed, and the internal space of frame 1 can be used for installing various electrical components. Preferably, height-adjustable support feet 11 are installed on the bottom of the rack 1 to meet different height requirements, and have strong versatility.

[0020] Among them, the high lock nut is transferred from the vibration plate 2 to the direct vibrator 3, and then to the blocking and separation mechanism 4; the vibrating plate 2 and the direct vibrator 3 belong to the structure commonly used in the field of mechanical processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com