Machining technology method of hole in automobile instrument board cross beam

A technology for automobile dashboards and processing technology, which is applied in the direction of piercing tools, metal processing equipment, manufacturing tools, etc., and can solve problems such as difficult ejection of the mold and inability of the core mold Z to move radially

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

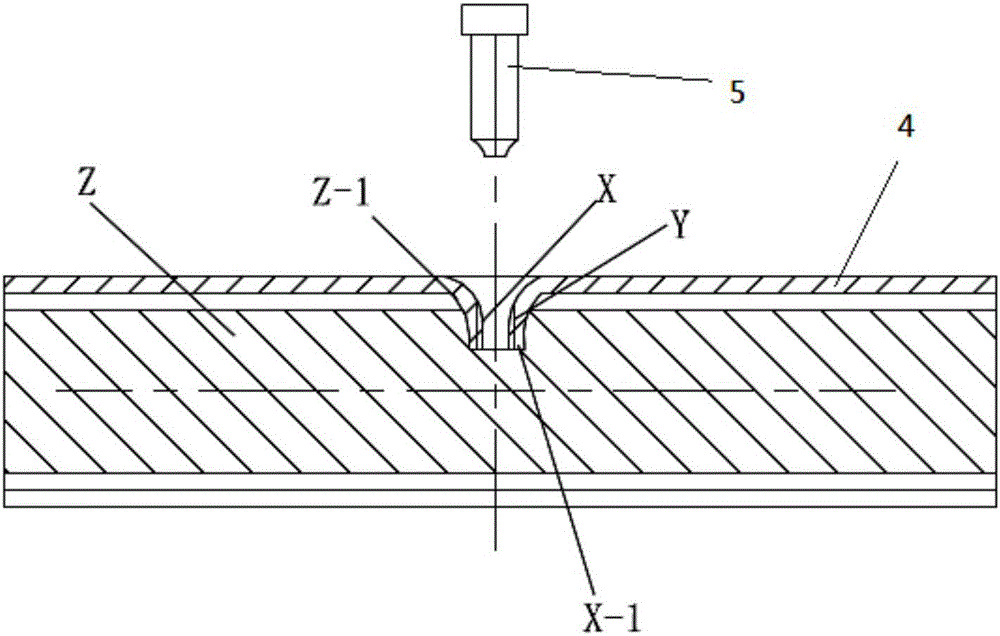

[0012] Specific implementation mode 1: Please refer to Figure 3 to Figure 8 , this embodiment is completed by the following steps:

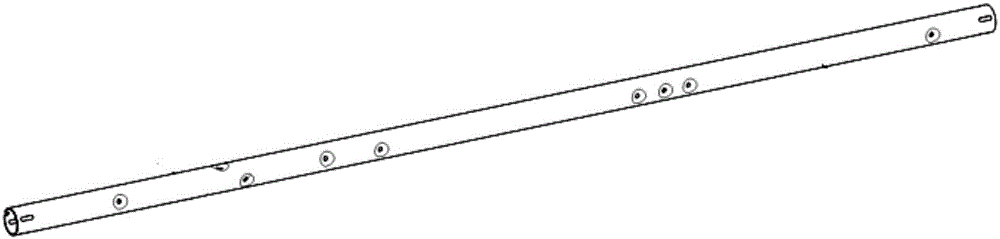

[0013] 1. Docking the left mandrel 1 with the right mandrel 2 to form a mandrel Z, the mandrel Z is a rod-shaped overall structure;

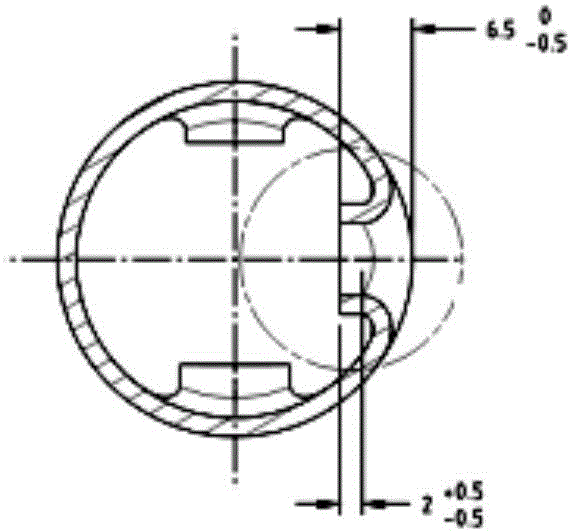

[0014] The right end face of described left mandrel 1 is provided with a regular quadrangular pyramid 1-1, and the centerline of regular quadrangular pyramid 1-1 coincides with the axis line of left mandrel 1, and the center line of described right mandrel 2 A regular square pyramid hole 2-1 is arranged on the left end face, the center line of the regular square pyramid hole 2-1 coincides with the axis line of the right mandrel 2, and the regular square pyramid 1-1 is inserted into the regular square pyramid hole 2-1 A detachable fixed fit is formed in the middle, and a die hole 3 is opened on the circumferential surface of the annular seam 3-1 where the left mandrel 1 and the right mandrel 2 are butted, and the ...

specific Embodiment approach 2

[0026] Specific implementation method two: please refer to Figure 9 The difference between this embodiment and Embodiment 1 is that the center line of the die hole 3 is located on the regular quadrilateral diagonal of the regular quadrangular pyramid 1-1 and the regular quadrangular pyramid hole 2-1 cross-section, and the regular quadrangular pyramid 1-1 and An interference fit is formed between one set of opposite faces of the regular quadrangular pyramid hole 2-1, and a gap fit is formed between the other set of opposite faces, and the fit gap is 0.04 mm to 0.06 mm. In this way, the interference fit formed between the regular quadrangular pyramid 1-1 and a group of opposite faces of the regular quadrangular pyramid hole 2-1 is to form a reliable fixed connection between the left mandrel 1 and the right mandrel 2, The clearance fit formed between another set of opposite faces is required for positioning. And if the two sets of opposite faces form an interference fit, it is ...

specific Embodiment approach 3

[0028]Specific implementation mode three: please refer to Figure 10 , the difference between this embodiment and Embodiment 1 is that the core mold Z is composed of the middle section including the left core mold 1 and the right core mold 2, the left extension section Z-3 and the right extension section Z-4, and the left extension section Z -3 and the outer surface diameter of the right extension section Z-4 are smaller than the outer surface diameter of the middle section, and the gap between the outer surface diameter of the middle section and the inner hole of the beam tube 4 is 0.15 to 0.25 mm. The advantage of this setting is that the gap between the outer surface diameter of the middle section and the inner hole of the beam tube 4 is relatively small, and when the inner convex part X-1 is filled into the mold hole Z-1 of the core mold Z, the left core mold 1 and the splitting force of the mandrel 2 on the right are basically offset by the frictional force that hinders m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large head diameter | aaaaa | aaaaa |

| Small head diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com