Welding method of Q460GJC steel used for architectural structure

A technology of steel for building structures and welding methods, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problems of increased welding difficulty, high Ni content, and unformed welding methods and processes, etc. Achieve the effect of meeting welding quality requirements, full objectivity and rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

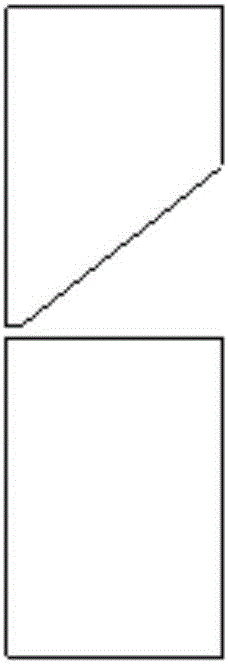

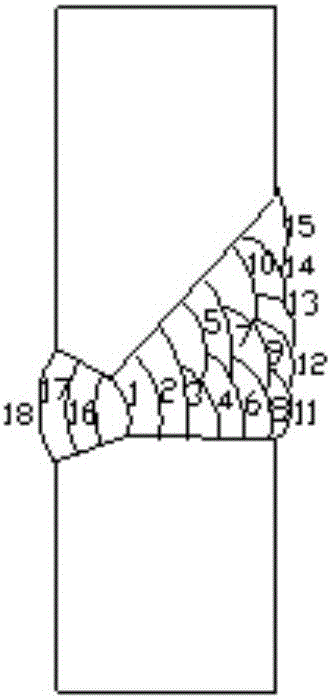

[0036] Butt horizontal welding with plate thickness 20mm+20mm, using CO 2 +Ar gas shielded welding, the size of both plates is 20*300*610mm, choose a single-sided V-shaped groove of 45°, blunt edge of 2mm, root gap of 2mm; 9 layers of 18 welding, specific joint and groove form schematic diagram, The schematic diagram of welding bead layout is as follows: figure 1 and figure 2 shown.

no. 2 example

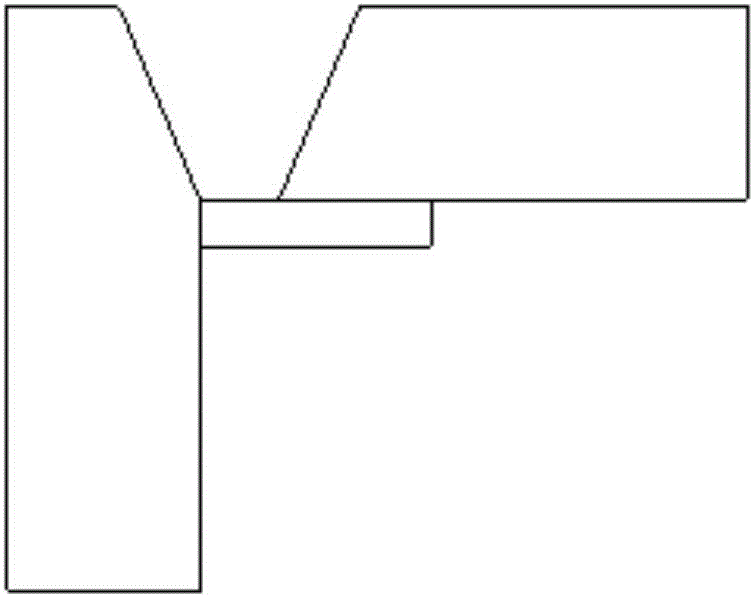

[0038] Corner butt flat welding of plate thickness 20mm+20mm, using submerged arc automatic welding, the size of both plates is 20*200*400mm, choose V-shaped groove 46°, blunt edge 2mm, root gap 10mm, back lining steel liner ; 7 layers and 11 welds, the specific schematic diagram of the joint and groove form, and the schematic diagram of the weld bead layout are as follows: image 3 and Figure 4 shown.

no. 3 example

[0040] Corner butt flat welding of plate thickness 20mm+20mm, using CO 2 +Ar gas shielded welding, the size of both plates is 20*200*400, choose V-shaped groove 46°, blunt edge 2mm, root gap 10mm, back lining steel liner; 7 layers 14 welding, specific joints and slopes The schematic diagram of the opening form and the layout of the welding bead are as follows: image 3 and Figure 5 shown.

[0041] Welding materials involved include:

[0042] Submerged arc welding automatic welding wire: MCJ60 GJ, Solder SJ101.

[0043] CO 2 +Ar gas shielded welding uses solid wire: WH60-GJ,

[0044] Welding equipment involved:

[0045] Submerged arc automatic welding welding equipment model ZD5-1600,

[0046] CO 2 +Ar gas shielded welding equipment model YD-500KR, the polarity is DC reversed.

[0047] The soldering condition is that the flux is baked at 300-350°C for 2 hours before use.

[0048] The ambient temperature of welding is -7~-8℃, and the ambient humidity is 62%. Clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com