Electric insulated clamp

An insulating clamp, electric power technology, applied in the direction of pliers, manufacturing tools, hand-held tools, etc., can solve the problems of insufficient occlusal force, poor insulation performance, etc., to increase friction, ensure insulation coefficient, and increase friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

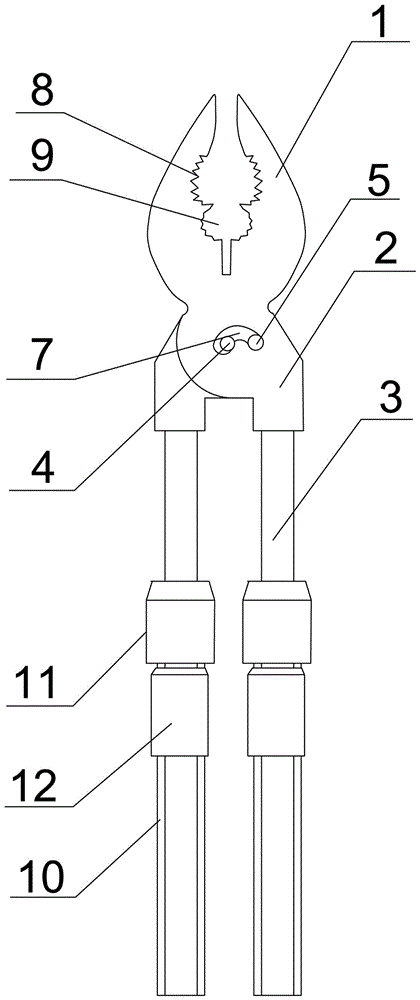

[0035] Such as Figure 1-3 As shown, an electrically insulated clamp includes two clamp bodies and a connecting mechanism. The clamp body includes a clamp mouth 1, a clamp jaw 2 and a clamp handle 3 that are sequentially connected. The jaw 1 and the jaw 2 are an integral structure. The handle 3 is fixedly connected with the jaw 2;

[0036] The two pliers bodies are connected together by a connecting mechanism arranged in the center of the pliers body. The connecting mechanism includes a main connecting hole 4, a secondary connecting hole 5 and a connecting shaft 6, and a sliding groove 7 is provided between the main connecting hole 4 and the secondary connecting hole 5. , The inner diameter of the main connecting hole 4, the inner diameter of the auxiliary connecting hole 5, and the groove width of the sliding groove 7 are respectively adapted to the diameter of the connecting shaft 6. In this embodiment, the connecting shaft 6 is located in the main connecting hole 4; the top of...

Embodiment 2

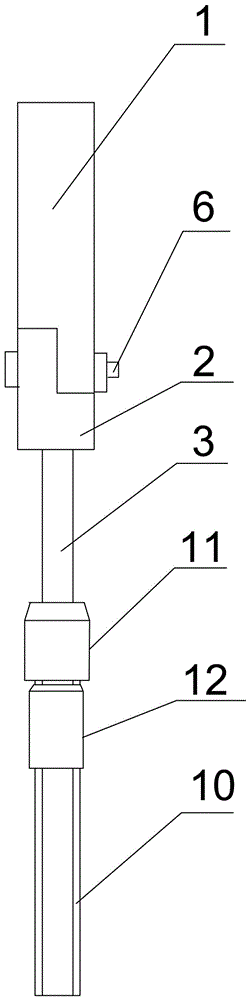

[0045] Such as Figure 4 As shown, an electrically insulated clamp includes two clamp bodies and a connecting mechanism. The clamp body includes a clamp mouth 1, a clamp jaw 2 and a clamp handle 3 that are sequentially connected. The jaw 1 and the jaw 2 are an integral structure. The handle 3 is fixedly connected with the jaw 2;

[0046] The two pliers bodies are connected together by a connecting mechanism arranged in the center of the pliers body. The connecting mechanism includes a main connecting hole 4, a secondary connecting hole 5 and a connecting shaft 6, and a sliding groove 7 is provided between the main connecting hole 4 and the secondary connecting hole 5. , The inner diameter of the main connecting hole 4, the inner diameter of the auxiliary connecting hole 5, and the groove width of the sliding groove 7 are respectively adapted to the diameter of the connecting shaft 6. In this embodiment, the connecting shaft 6 is located in the auxiliary connecting hole 5; the top ...

Embodiment 3

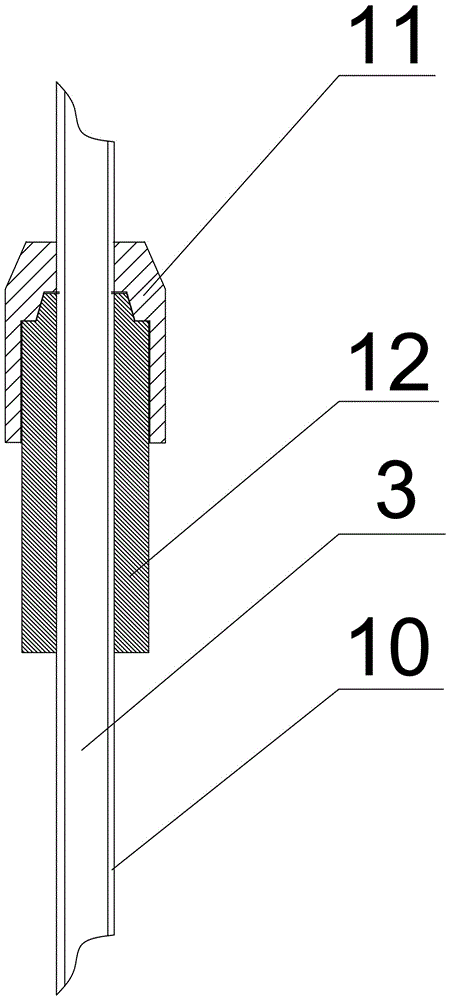

[0055] Such as Figure 5 As shown, an electrically insulated clamp includes two clamp bodies and a connecting mechanism. The clamp body includes a clamp mouth 1, a clamp jaw 2 and a clamp handle 3 that are sequentially connected. The jaw 1 and the jaw 2 are an integral structure. The handle 3 is fixedly connected with the jaw 2;

[0056] The two pliers bodies are connected together by a connecting mechanism arranged in the center of the pliers body. The connecting mechanism includes a main connecting hole 4, a secondary connecting hole 5 and a connecting shaft 6, and a sliding groove 7 is provided between the main connecting hole 4 and the secondary connecting hole 5. , The inner diameter of the main connecting hole 4, the inner diameter of the auxiliary connecting hole 5 and the groove width of the sliding groove 7 are respectively adapted to the diameter of the connecting shaft 6; the top of the jaw 1 is provided with a first jaw 8, which is located near the end of the jaw 2 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com