Full-automatic lentinus edodes stipe cutting equipment

A technology of shiitake mushroom stipe and cutting equipment, which is applied in metal processing, food processing, application, etc., can solve the problems of a large amount of labor, poor processing quality, lack of shiitake mushroom sorting and positioning technology, etc., and achieves small footprint, low manufacturing cost, cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

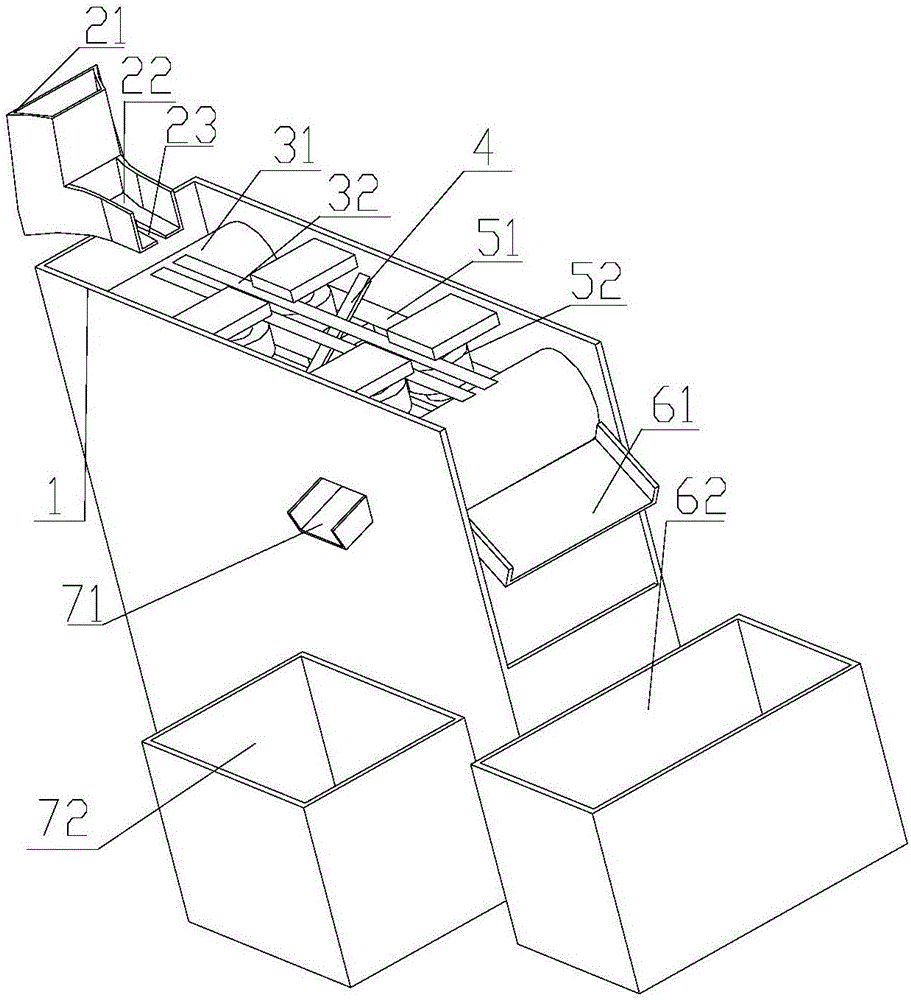

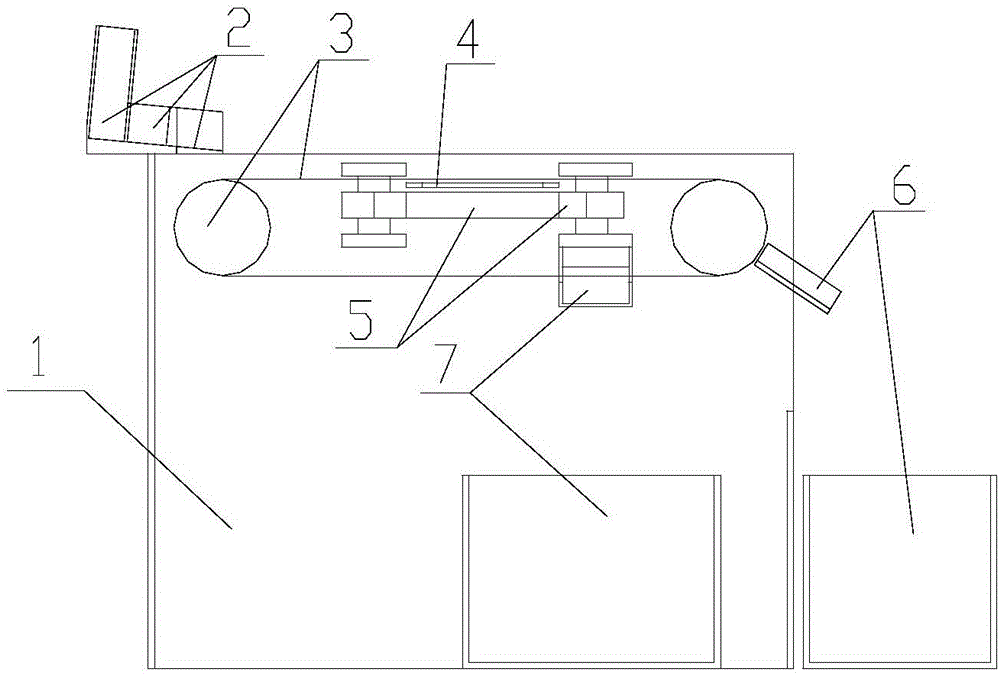

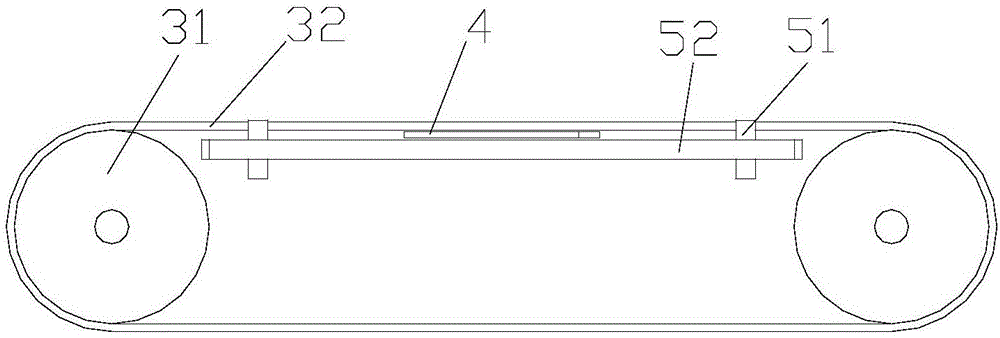

[0031] The full-automatic shiitake mushroom stipe cutting equipment that present embodiment provides, its structure is as follows: figure 1 and figure 2 As shown, it includes a box frame 1 and a conveying mechanism 3 installed in the box frame 1, a stipe cutting mechanism 4 and a clamping mechanism 5. The box frame 1 is an open box structure at the top, and the box The tail end of the body structure has a notch groove with an opening facing upwards. The upper part of the notch groove is the first discharge port. The cap collector 6 is arranged at the first discharge port. The cap collector 6 includes a The cap slideway 61 at the mouth, the cap slideway 61 is inclined downward, and the cap collection box 62 is installed below the cap slideway 61; on the side wall of the box frame 1, it is near the first discharge port There is a second discharge port, the second discharge port is provided with a stipe collector 7, and the stipe collector 7 includes a stipe slideway 71 install...

Embodiment 2

[0038] Such as Figure 10 As shown, the vibrating hopper 21 includes a hopper body 215. The bottom of the hopper body 215 has an upper base groove 211. The upper base groove 211 is connected with the head end of the mushroom track 22 and communicates with each other. The base 213 is fixedly connected, the lower base 213 is provided with an electromagnetic exciter 214, the electromagnetic exciter 214 includes an electromagnet iron core with a coil and an armature, the electromagnet iron core is installed on the lower base 213, and the armature is installed in the upper base groove 211 The electromagnet core is connected to the armature through a spring, and the electromagnet core is connected to the controller, and the electromagnet core is controlled to work periodically and intermittently through the controller. In addition, the hopper body 215 has an upper end inlet, and an outlet is formed at the joint of the mushroom track 22 on the lower upper base groove 211 of the hoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com