Reprocessing process for waste sponge with negative ions

A negative ion, reprocessing technology, applied in recycling technology, mechanical material recycling, plastic recycling, etc., can solve the problems of low sponge performance, antibacterial properties, and safety is difficult to guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is not limited to the following specific embodiments. Those skilled in the art can implement the present invention in various other specific embodiments according to the disclosure of the present invention, or make simple changes by adopting the design structure and ideas of the present invention Or changed, all fall within the scope of protection of the present invention.

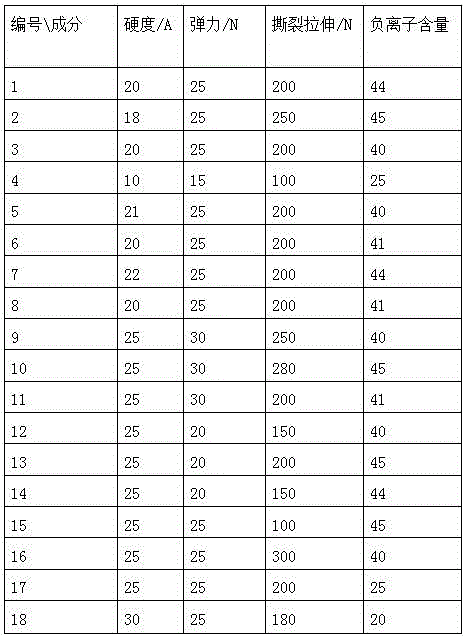

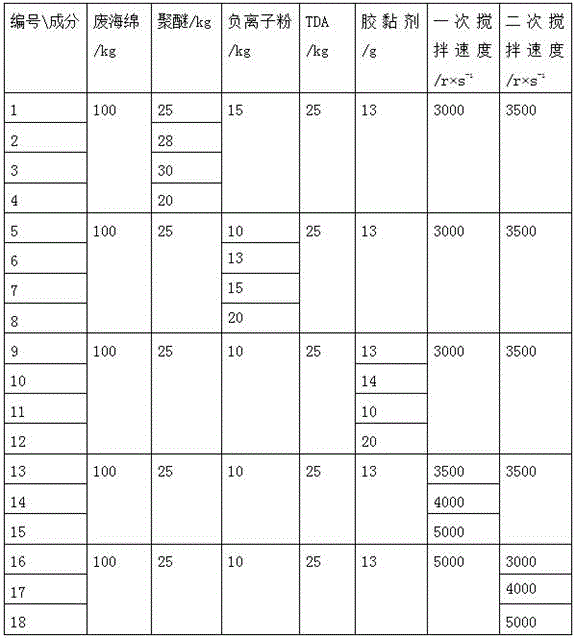

[0011] A specific embodiment of the present invention is a process for reprocessing waste sponges with negative ions, which includes the following steps: ① Coarsely grind, finely grind, and filter 100 parts of waste sponges to reach a particle size of 20 meshes; ② Add 25-30 parts of polyether , mix evenly, gradually heat up to 140°C and heat for 2 hours, so that the water content of the material is 0.01-0.02%, then cool down to 70-80°C, add 25 parts of TDA, stir for 30-60min, stirring speed 3000r / min, ③add 10-15 parts of negative ion powder, 13-14 parts of adhesive (such as epo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com