Mobile type pipe production system engineering vehicle

A system engineering vehicle and mobile technology, applied in the field of pipe manufacturing, can solve the problems of high transportation cost and difficulty in pipe transportation, achieve the effects of expanding the development area, rapid and accurate maintenance and repair, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

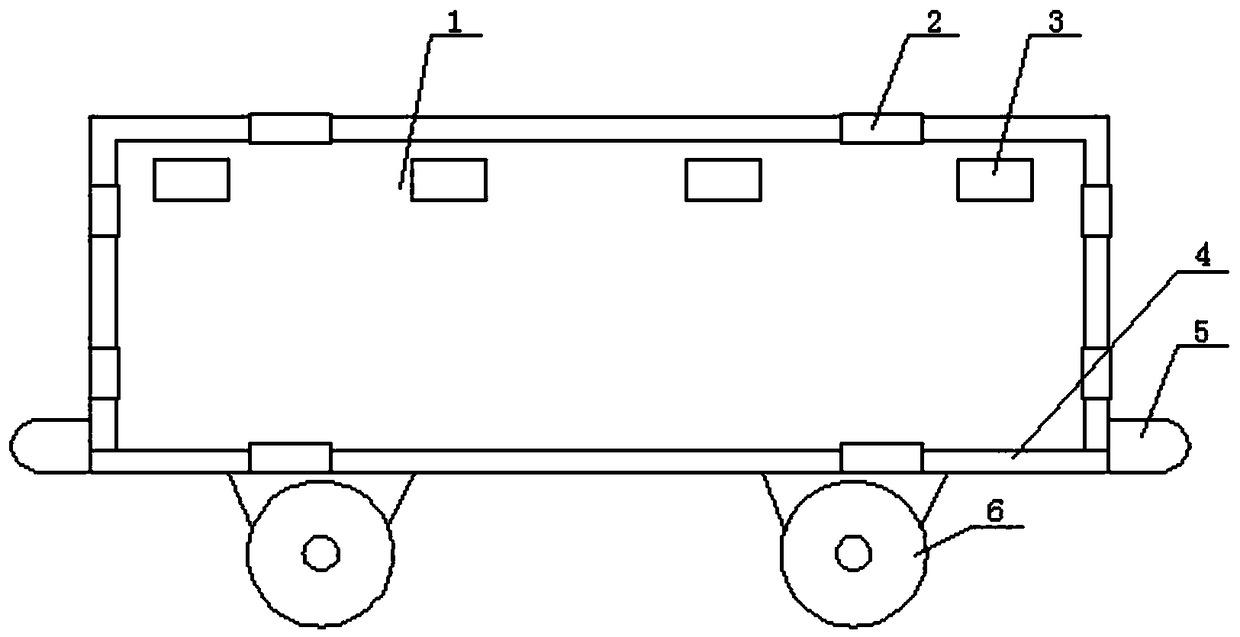

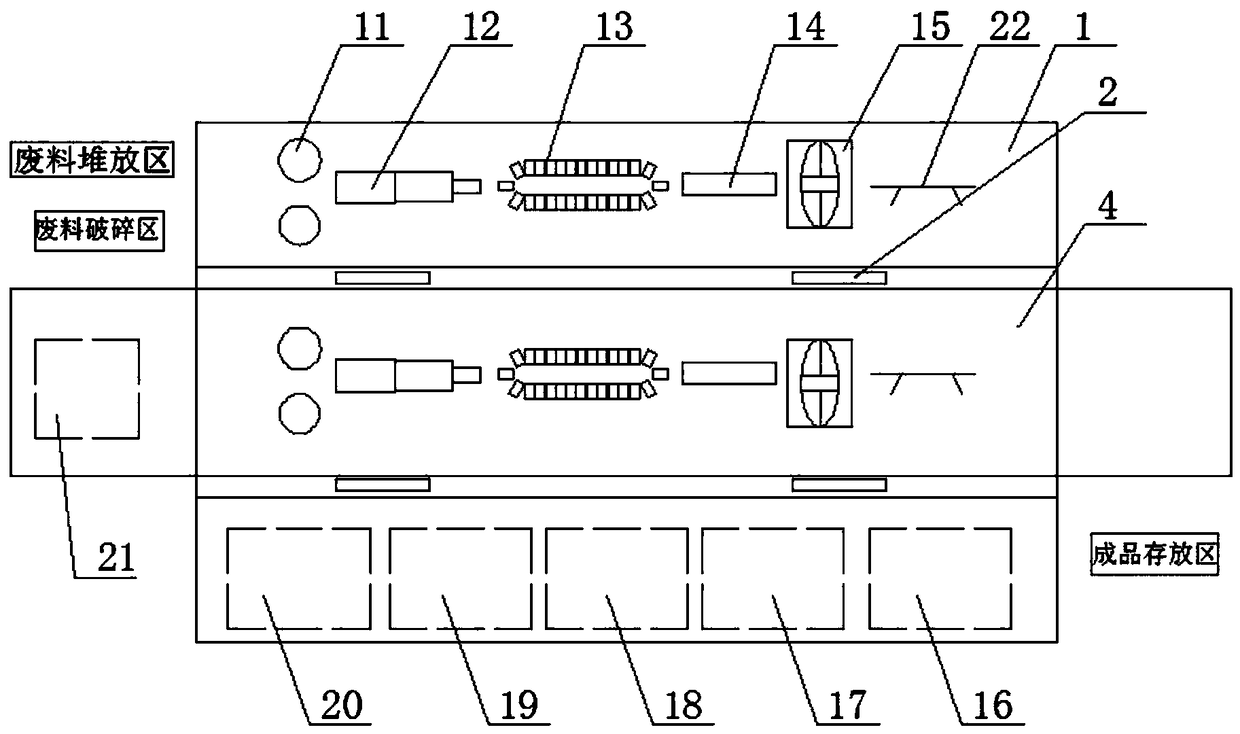

[0043] An engineering vehicle for threaded pipe production system, including a vehicle body, two side panels are opened and fixed horizontally, and a production line is respectively installed on the bottom panel and one side panel, and each production line is composed of a mixer 11, an extruder 12, Screw extrusion machine 13, cooler 14, cutting machine 15 and quality inspection table 22.

[0044] On the inner elevation of the other side plate, there are respectively a raw material storage area 20, a temporary pipe fitting storage area 19, a construction equipment storage area 18, a test and detection sample storage area 17, and a purchased pipe fitting storage area 16, etc. At the edge of the car body, areas such as finished product storage area, waste material storage area, and waste material crushing area can also be set to facilitate production.

[0045] A production line controller 21 is placed at the position where the front side plate is opened horizontally to control th...

Embodiment 2

[0047] A multi-type pipe production system engineering vehicle, which can produce multiple types of pipes, such as PE63A, PE75A, PE250A, PE630A, PE315A. Five parallel production lines are respectively installed on one side plate, and each production line is composed of a mixer 31 , an extruder 33 , a vacuum sizing sleeve 34 , a printing machine 35 , a tractor 36 , a cutting machine 15 and a quality inspection station 22 . Among them, there are three mixers. Different types of vacuum sizing sleeves produce different types of pipes.

[0048] On the inner elevation of the other side plate, there are respectively a raw material storage area 20, a temporary pipe fitting storage area 19, a construction equipment storage area 18, a test and detection sample storage area 17, and a purchased pipe fitting storage area 16, etc. At the edge of the car body, areas such as finished product storage area, waste material storage area, and waste material crushing area can also be set to facili...

Embodiment 3

[0051] In order to fully illustrate the technical solution of the present application, the following embodiments of various production elements that are completely placed after the carriage is closed in the transportation state are provided. The following is only one form, and the present application also has many forms.

[0052] The engineering vehicle body is provided with a preparation unit I, a production unit III, and a delivery unit II, wherein the preparation unit is arranged on the right side of the upper surface of the vehicle body floor, the production unit is arranged at the front part of the left side of the upper surface of the vehicle body floor, and the delivery unit Arranged at the left rear part of the upper surface of the bottom plate of the car body, the three units are reasonably arranged in the body of the engineering vehicle. Through the cooperation of the above units, the pipes can be produced quickly and conveniently. The auxiliary unit is a single vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com