Elevator sill

A technology for sills and elevators, applied in the field of machinery, can solve problems affecting the normal use of elevator sills, degumming of noise-absorbing strips, etc., and achieve the effects of reducing noise, improving reliability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

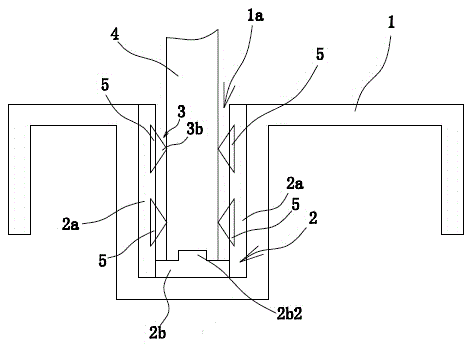

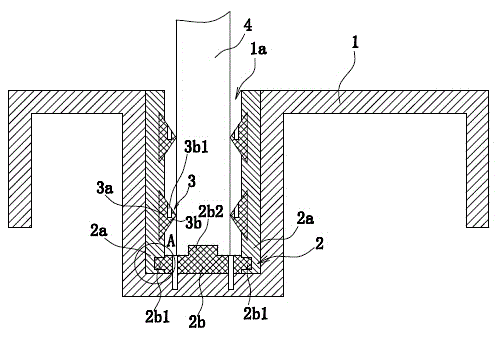

[0029] Such as figure 1 Shown, this elevator sill is made up of sill body 1, sliding sleeve 2, rubber strip 3 etc. Wherein, the middle part of the sill body 1 is recessed downwards to form a strip-shaped chute 1a, and the sliding sleeve 2 is fixed in the chute 1a.

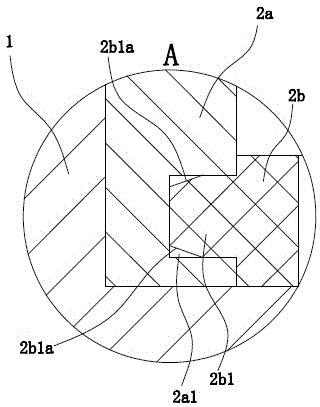

[0030] Specifically, the sliding sleeve 2 is elongated and arranged along the length direction of the sliding slot 1a. The cross section of the sliding sleeve 2 is concave, and the sliding sleeve 2 includes two vertically arranged side plates 2a and a bottom plate 2b between the two side plates 2a. Wherein, the bottom plate 2b is arranged along the horizontal direction, the bottom plate 2b abuts against the bottom wall of the chute 1a, and the bottom plate 2b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com