Chemical liquid bottle and manufacturing method thereof

A liquid medicine bottle and bottleneck technology, which is applied in the field of medicine liquid bottle and its manufacturing, can solve problems such as difficult sterilization process, low production efficiency, and impact on sterility, so as to save multiple processes, improve production efficiency, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

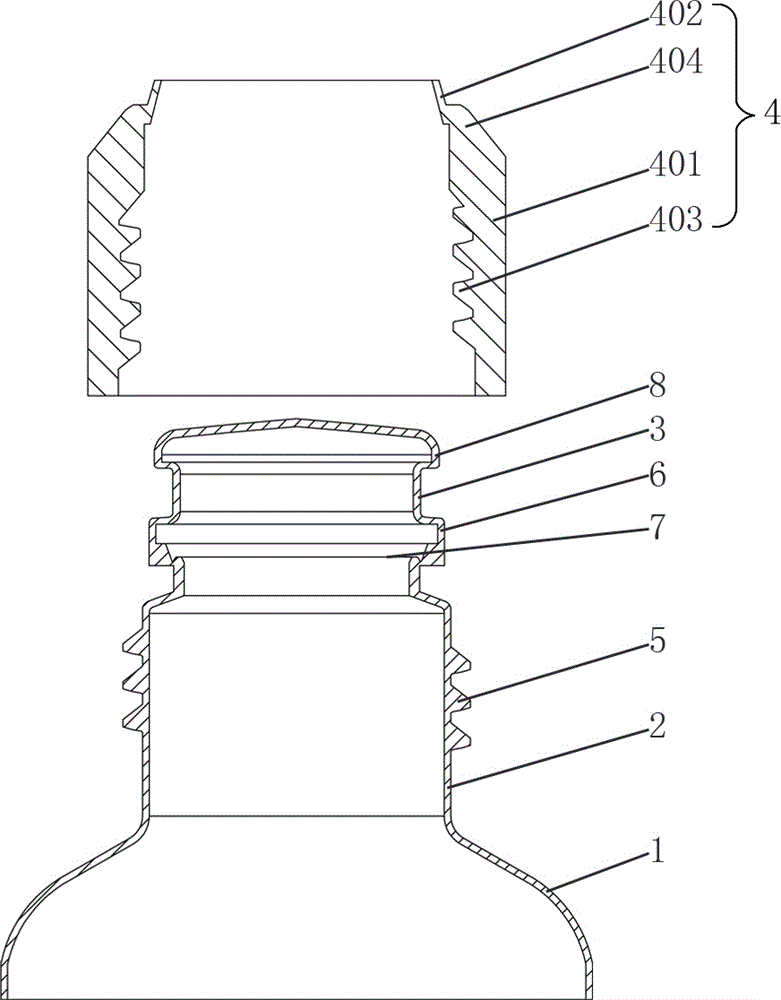

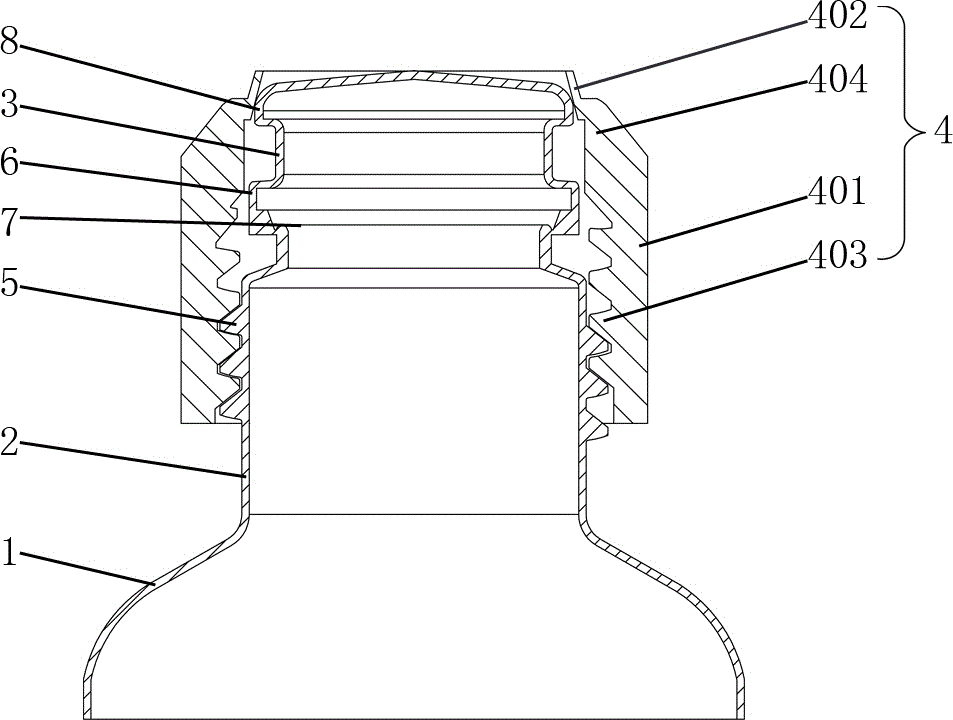

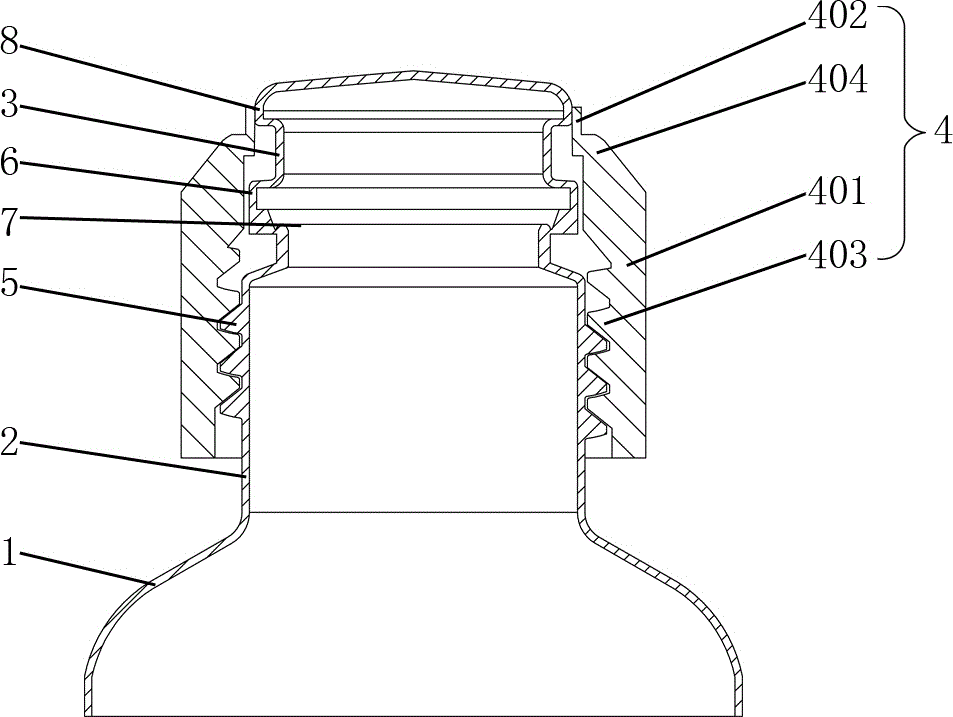

[0023] Such as figure 1 , figure 2 , Figure 6 As shown, this liquid medicine bottle includes a bottle body 1 made of plastic, a bottleneck 2, a sealing end cap 3 and a screw sleeve 4; the bottleneck 2 is arranged on the upper end of the bottle body 1, and the outer surface of the bottleneck 2 is provided with external threads 5. The lower end of the sealing end cap 3 protrudes outward to form an annular connecting portion 6, the sealing end cap 3 is connected to the upper end of the bottle neck 2 through its annular connecting portion 6, and an annular cut line 7 is provided between the sealing end cap 6 and the bottle neck 2 The bottle body 1, the bottleneck 2, and the sealing end cap 3 are integrally blow-molded; the upper end of the sealing end cap 3 is provided with an outwardly protruding annular convex portion 8; body 401...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com