A preparation method of modified heu-type zeolite and its application as nitrogen selective adsorbent

A modification and zeolite technology, which is applied in the direction of sodium zeolite, chemical instruments and methods, and other chemical processes, can solve the problems of artificially synthesized HEU-type zeolite such as long synthesis period and poor repeatability, and achieve N2 selective adsorption performance improvement, crystallization Shorter chemical cycle and better composition stability

Active Publication Date: 2017-03-22

LUOYANG JALON MICRO NANO NEW MATERIALS CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is to provide a preparation method of modified HEU-type zeolite and its application as a nitrogen selective adsorbent, so as to solve the technical problems of artificially synthesized HEU-type zeolite with long synthesis period and poor repeatability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

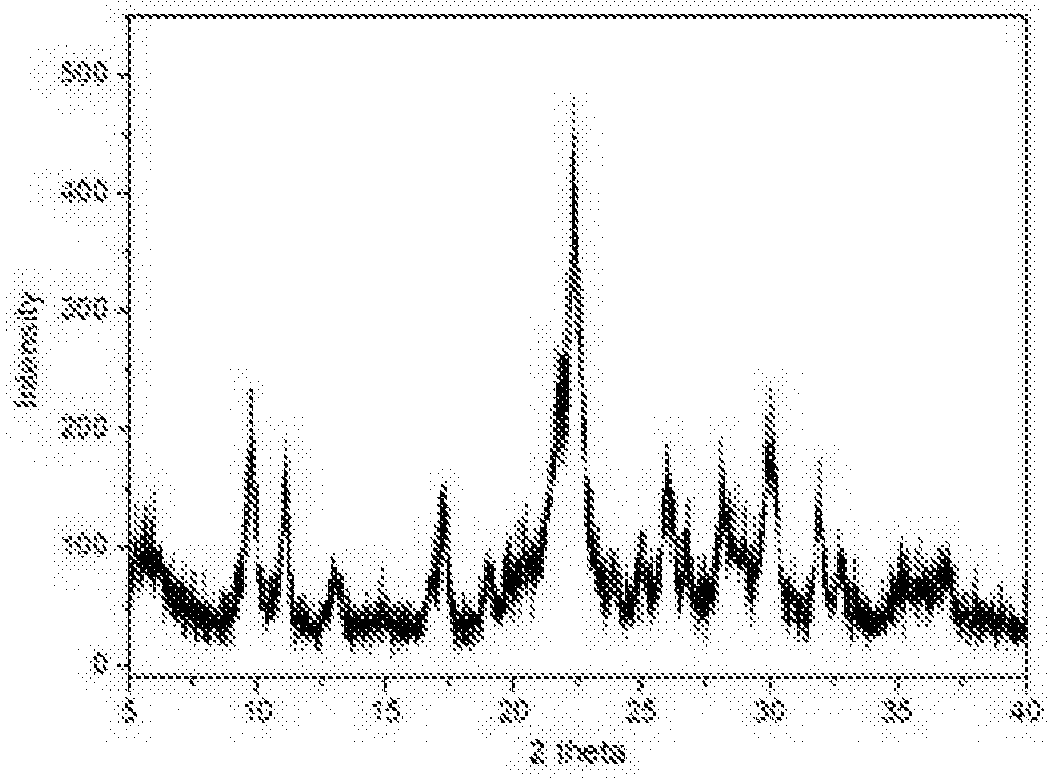

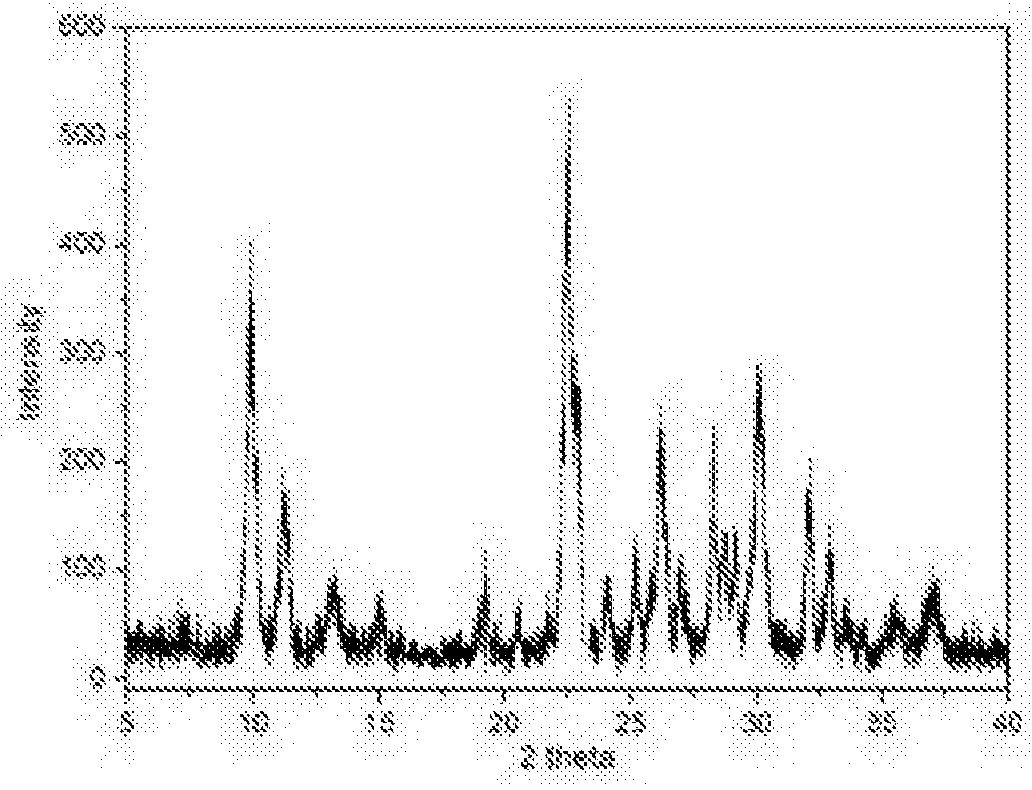

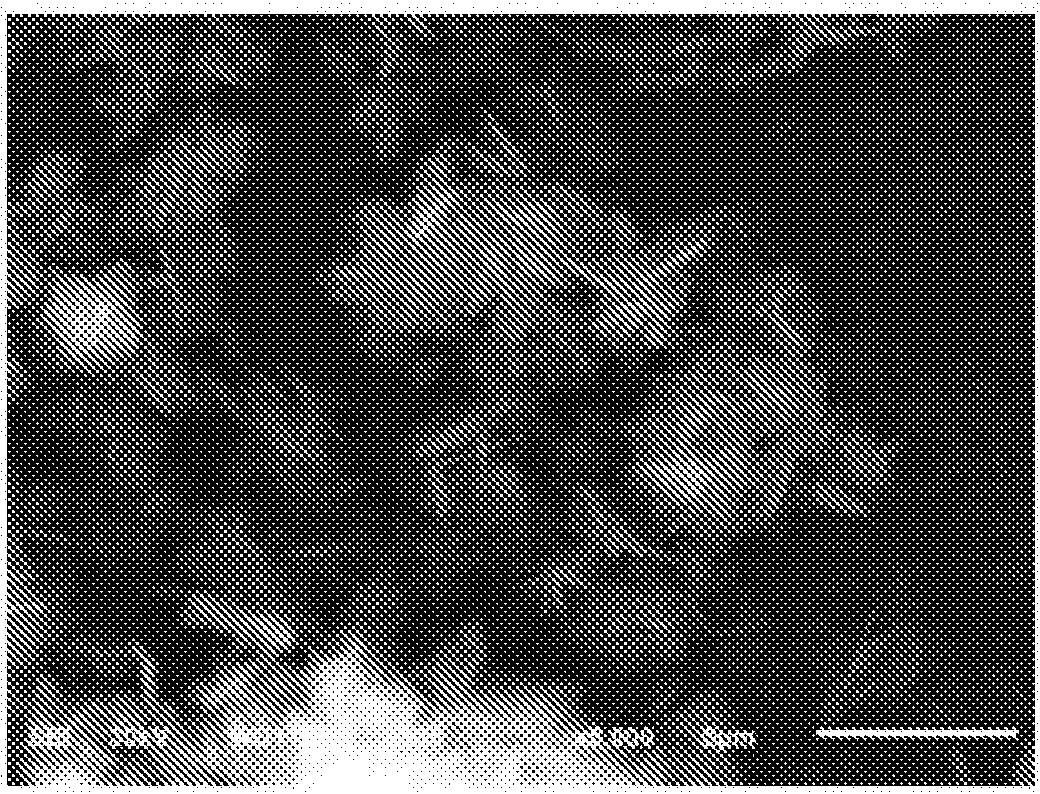

The invention introduces a preparation method of modified HEU type zeolite and an application of the modified HEU type zeolite as a nitrogen selection adsorbent. The preparation method comprises the following steps of uniformly mixing SiO2 with Al2O3, Na2O, K2O and H2O according to the mole ratio of the SiO2 to the Al2O3, to the Na2O, to the K2O and to the H2O being (8-20) to 1 to (0.5-3) to (0.5-3) to (300-800) to obtain initial aluminosilicate sol, then adding artificial synthesis structure induction species of which the mass percentage is about 1-20%, performing low-temperature ageing, performing high-temperature crystallization, performing solid-liquid separation, and performing drying so as to obtain high-crystallinity HEU type zeolite. According to the preparation method disclosed by the invention, the crystallization period can be greatly shortened and can be shortened to 12h, and besides, the synthesized HEU type zeolite can be guaranteed to have small and uniform grain size (1-3[mu]m); and after ion exchange modification, different ion exchange modified adsorbents can be obtained, and the selective adsorption capacity of the adsorbents to N2 in N2 / CH4 mixed gas is obviously improved and can be improved by 2-15 times.

Description

A kind of preparation method of modified HEU type zeolite and its application as nitrogen selective adsorbent technical field The invention relates to a technology in the field of chemical adsorbents, in particular to a preparation method of a modified HEU type zeolite and its application as a nitrogen selective adsorbent. Background technique Natural clinoptilolite with HEU-type framework structure is the most widely existing zeolite molecular sieve in nature. There are two kinds of HEU-type structure zeolite materials: heulandite and clinoptilolite. Natural clinoptilolite can be used as a gas adsorbent in industry, and its cation composition and quantity can be changed by ion exchange technology, so as to realize artificial regulation of natural clinoptilolite's selective adsorption performance. Natural clinoptilolite can be widely used in the field of water treatment to remove impurities such as heavy metal ions and ammonia nitrogen in wastewater. However, due to the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B39/52C01B39/50B01J20/18

CPCB01J20/18C01B39/50C01B39/52C01P2002/72C01P2004/03C01P2004/61C01P2006/80

Inventor 闫文付余成磊魏渝伟白璞

Owner LUOYANG JALON MICRO NANO NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com