Organic processing system for poultry and livestock manure and organic fertilizer preparation method

A livestock manure, organic treatment technology, applied in the preparation of organic fertilizer, organic fertilizer equipment, organic fertilizer and other directions, can solve the problems of low cleaning efficiency, harsh working environment, high labor intensity, etc., to reduce labor intensity, eliminate side effects, The effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

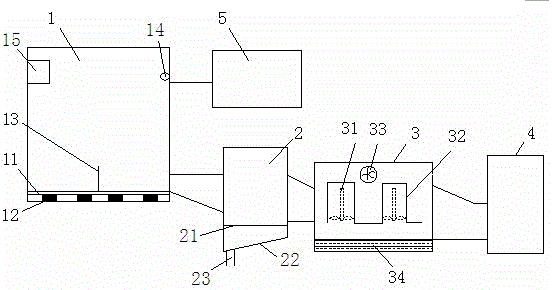

[0032] like figure 1Shown, a kind of poultry, livestock manure organic processing system, comprises poultry or livestock captive area 1, control unit 5, manure excretion amount detection unit, manure scraping unit 13, manure liquid filtering unit 2 and fermentation unit 3, wherein, all The poultry or livestock breeding area includes several captive units, each captive unit is arranged parallel to each other, and there is a passageway for people to walk between two adjacent captive units, and several captive units are collected to the No. A conveying pipeline, the first conveying pipeline is connected with the feces liquid filtering unit 2, the fecal liquid filtering unit 2 is connected with the fermentation unit 3 through the second conveying pipeline, and the ground of the poultry or livestock breeding area 1 is provided with feces excretion capacity Detection unit, poultry or livestock breeding area 1 opposite wall is provided with said excrement scraping unit 13, and said f...

Embodiment 2

[0041] like figure 1 Shown, a kind of poultry, livestock manure organic processing system, comprises poultry or livestock captive area 1, control unit 5, manure excretion amount detection unit, manure scraping unit 13, manure liquid filtering unit 2 and fermentation unit 3, wherein, all The poultry or livestock breeding area includes several captive units, each captive unit is arranged parallel to each other, and there is a passageway for people to walk between two adjacent captive units, and several captive units are collected to the No. A conveying pipeline, the first conveying pipeline is connected with the feces liquid filtering unit 2, the fecal liquid filtering unit 2 is connected with the fermentation unit 3 through the second conveying pipeline, and the ground of the poultry or livestock breeding area 1 is provided with feces excretion capacity Detection unit, poultry or livestock breeding area 1 opposite wall is provided with said excrement scraping unit 13, and said ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com