A kind of black dyeing process of fur

A fur and craft technology, applied in the field of leather processing, can solve the problems of low blackness, large amount of dye, low dye absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

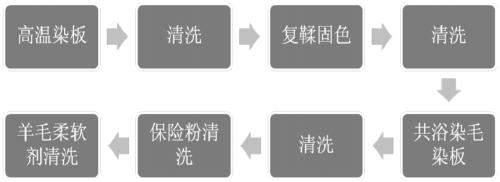

Method used

Image

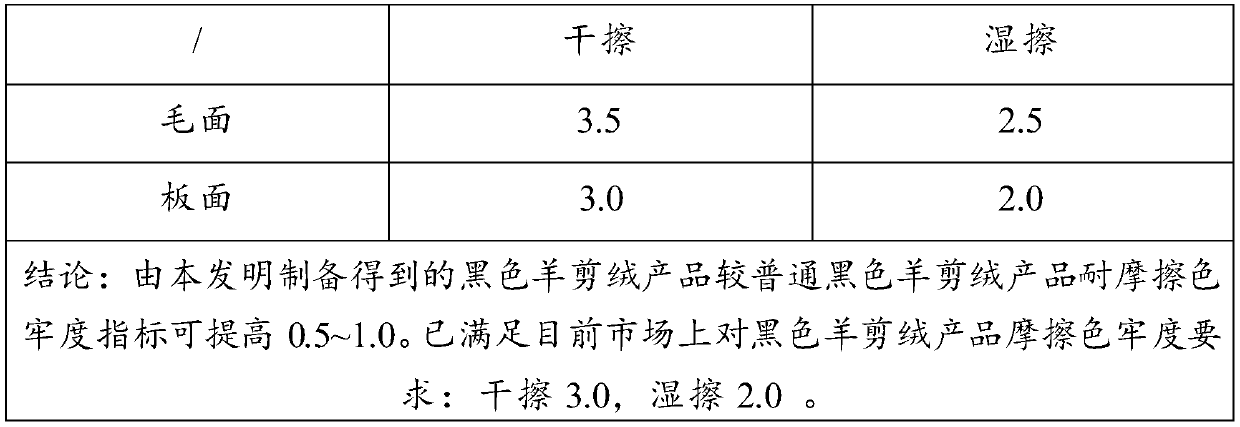

Examples

Embodiment 1

[0104] Put the hide into the inclined drum, liquid ratio 1:12, temperature 40°C, add 0.5g / L fatliquor CUTAPOL TIS, rotate for 60 minutes, add black dye SELLA FAST BLACK NT 2.5g / L, rotate for 60 minutes, add Formic acid 0.7g / L, rotate for 30 minutes, add fatliquor TRIANOL LC12, 1g / L, rotate for 60 minutes, then add formic acid 0.5g / L every 20 minutes, adjust the pH to 3.0-3.1. drain.

[0105] Add water at 25°C to the inclined drum with a liquid ratio of 1:12, wash for 10 minutes, and drain.

[0106]Add water at 40°C to the inclined drum, liquid ratio 1:12, add black dye SELLA FAST BLACK NT 2g / L, rotate for 60 minutes, add formic acid 0.5g / L, rotate for 30 minutes, add aluminum tanning agent PELLUTAX ALF 2g / L, rotate for 30 minutes, add chrome powder CHROMITAN B 2g / L, rotate for 30 minutes, add sodium bicarbonate 2g / L, rotate for 90 minutes, adjust the pH to 3.2-3.4, and drain.

[0107] Add water at 25°C to the inclined drum, the liquid ratio is 1:12, add 0.5g / L formic acid, ...

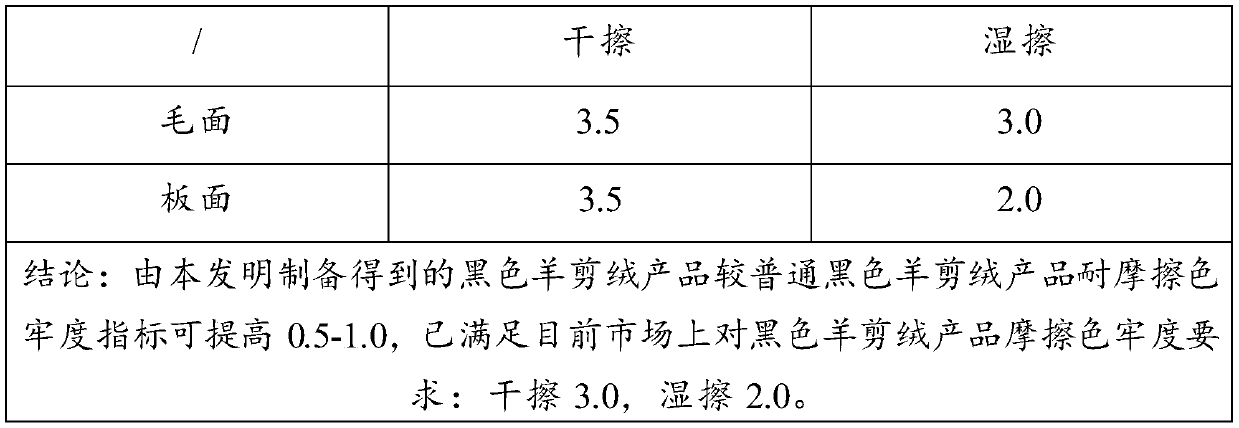

Embodiment 2

[0118] Put the hide into the inclined drum, liquid ratio 1:12, temperature 40°C, add 0.8g / L fatliquor CUTAPOL TIS, rotate for 60 minutes, add black dye SELLA FAST BLACK NT 2.6g / L, rotate for 60 minutes, add Formic acid 0.6g / L, rotate for 30 minutes, add fatliquor TRIANOL LC12, 1.1g / L, rotate for 60 minutes, then add formic acid 0.5g / L every 20 minutes, adjust the pH to 3.1~3.2. drain.

[0119] Add water at 25°C to the inclined drum with a liquid ratio of 1:12, wash for 10 minutes, and drain.

[0120] Add water at 40°C to the inclined drum, liquid ratio 1:12, add black dye SELLA FAST BLACK NT 2.1g / L, rotate for 60 minutes, add formic acid 0.5g / L, rotate for 30 minutes, add aluminum tanning agent PELLUTAX ALF 2.2g / L, rotate for 30 minutes, add chrome powder CHROMITAN B 2g / L, rotate for 30 minutes, add sodium bicarbonate 2g / L, rotate for 90 minutes, adjust the pH to 3.2-3.4, and drain.

[0121] Add water at 25°C to the inclined drum, the liquid ratio is 1:12, add 0.5g / L formic ...

Embodiment 3

[0132] Put the skin into the inclined drum, the liquid ratio is 1:12, the temperature is 42°C, add 0.5g / L fatliquor CUTAPOL TIS, rotate for 60 minutes, add black dye SELLA FAST BLACK NT 2.5g / L, rotate for 60 minutes, add Formic acid 0.8g / L, rotate for 30 minutes, add fatliquor TRIANOL LC12, 1.5g / L, rotate for 60 minutes, then add formic acid 0.5g / L every 20 minutes, adjust the pH to 3.0-3.1. drain.

[0133] Add water at 28°C to the inclined drum with a liquid ratio of 1:12, wash for 10 minutes, and drain.

[0134] Add water at 42°C to the inclined drum, liquid ratio 1:12, add black dye SELLA FAST BLACK NT 2g / L, rotate for 60 minutes, add formic acid 0.6g / L, rotate for 30 minutes, add aluminum tanning agent PELLUTAX ALF 2g / L, rotate for 30 minutes, add chrome powder CHROMITAN B 2g / L, rotate for 30 minutes, add sodium bicarbonate 2g / L, rotate for 90 minutes, adjust the pH to 3.2-3.4, and drain.

[0135] Add water at 25°C to the inclined drum, the liquid ratio is 1:12, add 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com