Antibacterial and deodorant finishing agent for footgear and preparation method thereof

A technology of finishing agent and footwear, which is applied in the field of antibacterial and deodorant finishing agent for footwear and its preparation, which can solve the problems of skin sterilization and achieve the best deodorizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

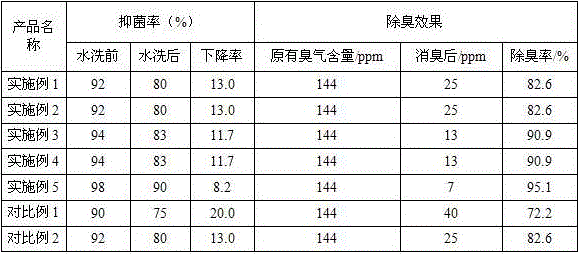

Examples

Embodiment 1

[0015] An antibacterial and deodorizing finishing agent for footwear, prepared by parts by weight of the following ingredients: 0.05 parts of chitosan, 1.2 parts of acetic acid, 0.1 parts of ethanolic extract of Chinese cylindrica, 0.2 parts of ethanolic extract of willow leaves, and Sorbus 4 parts of alcohol oleate, 8 parts of coco-betaine, 0.15 parts of decanol, 0.05 parts of Agastache vulgaris ethanol extract, 0.05 parts of ginger ether extract, 1.5 parts of white cardamom 30wt% ethanolic water extract, 6 parts of flavor, 100 parts of high purity water.

[0016] The preparation method of the above-mentioned antibacterial and deodorizing finishing agent for footwear is: (1) Chitosan, acetic acid, and high-purity water are stirred at a temperature of 20°C for 10 minutes, and then left to stand for defoaming; , Willow leaf ethanol extract, sorbitan oleate, coco betaine, stirring for 30 minutes; (3) Add decyl alcohol, Agastache vulgaris ethanol extract, ginger ether extract, white...

Embodiment 2

[0018] An antibacterial and deodorizing finishing agent for footwear, which is prepared by weight of the following ingredients: 0.12 parts of chitosan, 0.5 parts of acetic acid, 0.5 parts of ethanol extract of green leaves, 0.8 parts of ethanol extract of willow leaves, and Sorbus 8 parts of alcohol oleate, 4 parts of coco-betaine, 0.05 parts of decanol, 0.15 parts of Agastache vulgaris ethanol extract, 0.15 parts of ginger ether extract, 0.5 parts of white cardamom 30wt% ethanolic water extract, 2 parts of flavor, 150 parts of high purity water.

[0019] The preparation method of the above-mentioned antibacterial and deodorizing finishing agent for footwear is: (1) Chitosan, acetic acid, and high-purity water are stirred at a temperature of 40°C for 30 minutes, then stand still for defoaming; , Willow leaf ethanol extract, sorbitan oleate, coco betaine, stirring for 60 minutes; (3) Add decyl alcohol, Agastache vulgaris ethanol extract, ginger ether extract, white cardamom 30wt% ...

Embodiment 3

[0021] An antibacterial and deodorizing finishing agent for footwear, which is prepared by weight of the following ingredients: 0.07 parts of chitosan, 0.7 parts of acetic acid, 0.45 parts of ethanolic extract of cylindracea, 0.4 parts of ethanolic extract of willow leaves, and Pear 7 parts of alcohol oleate, 7 parts of coco-betaine, 0.12 parts of decanol, 0.12 parts of Agastache vulgaris ethanol extract, 0.12 parts of ginger ether extract, 1.1 parts of white cardamom 30wt% ethanol water extract, 5 parts of flavor, 120 parts of high purity water.

[0022] The preparation method of the above-mentioned antibacterial and deodorizing finishing agent for footwear is: (1) Chitosan, acetic acid, and high-purity water are stirred for 15 minutes at a temperature of 40°C, then stand still for defoaming; , Willow leaf ethanol extract, sorbitan oleate, coco-betaine, stirring for 45 minutes; (3) Adding decanol, ageratum ethanol extract, ginger ether extract, white cardamom 30wt% ethanol water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com