Novel steel-concrete composite bridge and construction method thereof

A concrete and bridge technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as urban traffic congestion, achieve the effect of novel materials, excellent quality, and solve the problem of urban traffic congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

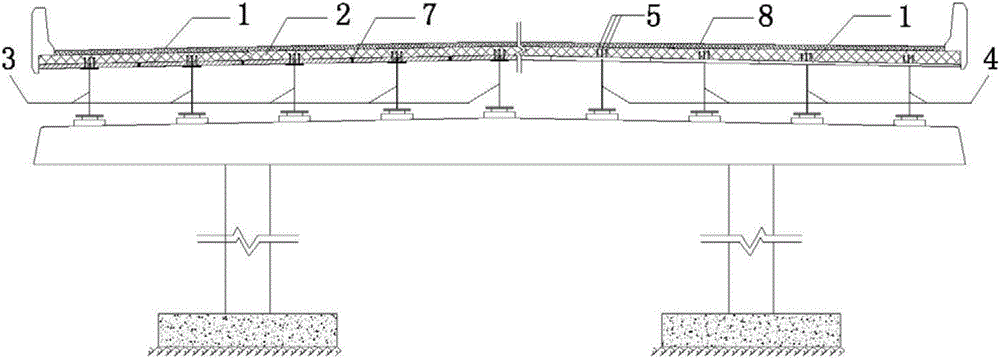

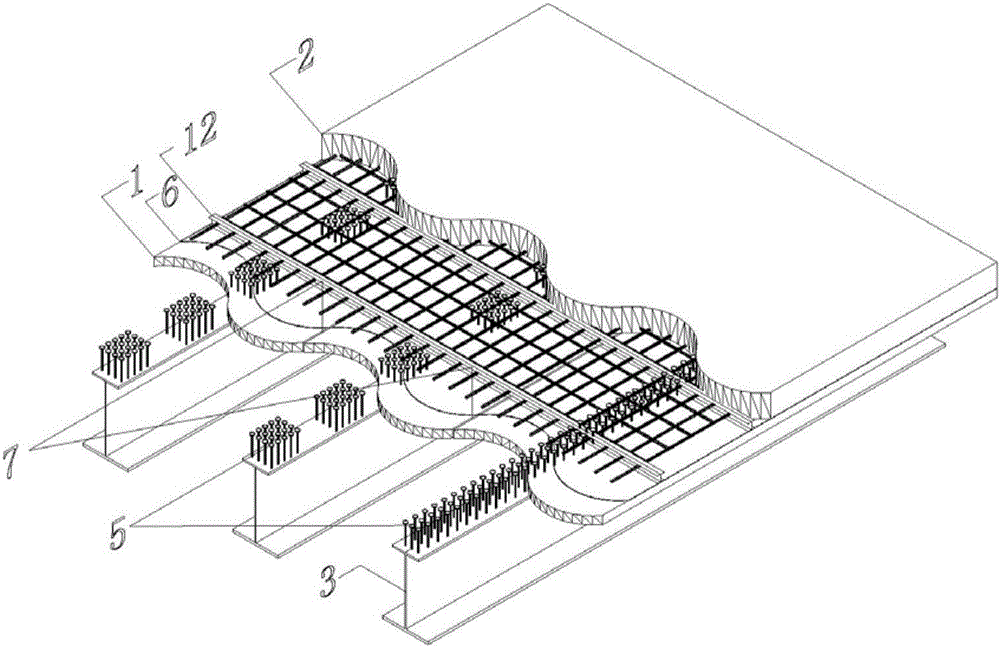

[0044] Such as figure 1 , 2 , 4-6, a new type of steel-concrete composite bridge, including the main girder, cast-in-place SAP internal curing concrete bridge deck 2 and shear nails 5. The main girder is formed by connecting the I-shaped steel beam 3 and the FRP plate 1, the upper flange plate of the I-shaped steel beam 3 is provided with shear nails 5, the FRP plate 1 is located on the top surface of the I-shaped steel beam 3, and the FRP plate 1 It is fixed by shear nails 5 and I-beam 3. A number of main girders (for example, 3 to 20 pieces) are assembled and erected along the transverse direction of the bridge, and all the main girders are connected by end connecting plates 11 along the longitudinal direction of the bridge to form a whole (the whole is formed by anchoring bolts of the end connecting plates along the longitudinal direction of the bridge to form a whole), forming a multi-hole joint. (the length of the porous primary girder is the bridge length between two a...

Embodiment 2

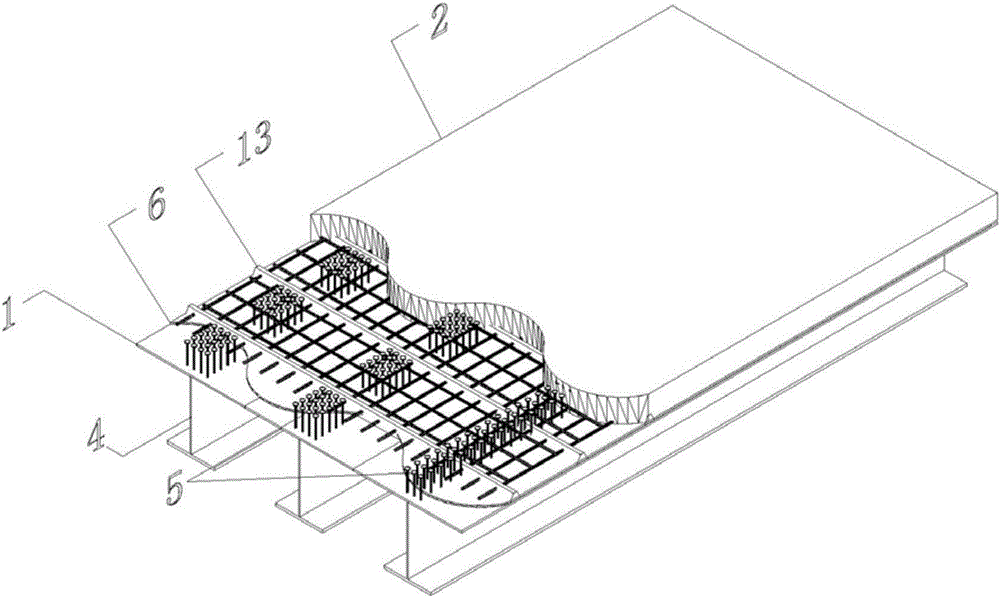

[0062] Such as figure 1 , 3 , 4-6, a new type of steel-concrete composite bridge, including the main girder, cast-in-place SAP internal curing concrete bridge deck 2 and shear nails 5. The main girder is a T-shaped steel girder 4, and the upper flange steel plate of the T-shaped steel girder 4 is provided with shear studs 5. The prefabricated T-shaped steel girder 4 is the main girder structure, and the whole is hoisted and placed on the temporary support 10, and several pieces (such as 3 to 20 pieces) are assembled and erected along the transverse bridge direction, and connected in sequence along the longitudinal direction of the bridge through the end connecting plate 11, The longitudinal seams of the upper flange steel plates (steel plates) of the T-shaped steel beam 4 are welded to form a whole prefabricated main girder to form a porous joint (the length of the porous single joint main girder is the length of the bridge between two adjacent expansion joints), Such as i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com