Building method for tailings warehouse

A construction method and technology for tailings ponds, applied in filling, construction, soil protection, etc., can solve the problem of waste of space resources in the middle and upper part of tailings ponds, insufficient utilization of land resources, and failure to improve storage capacity utilization, etc. problems, to achieve the effect of increasing effective storage capacity, high construction efficiency, and eliminating mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

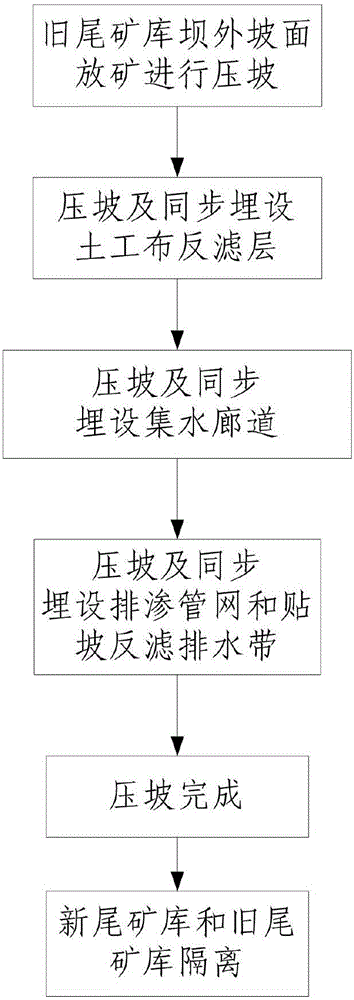

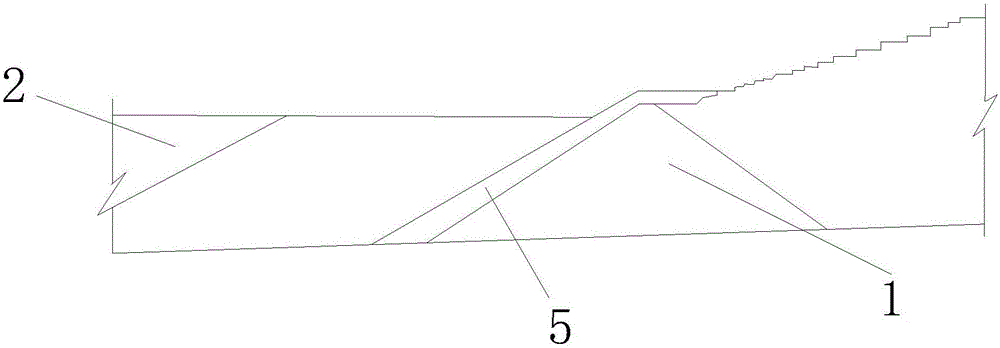

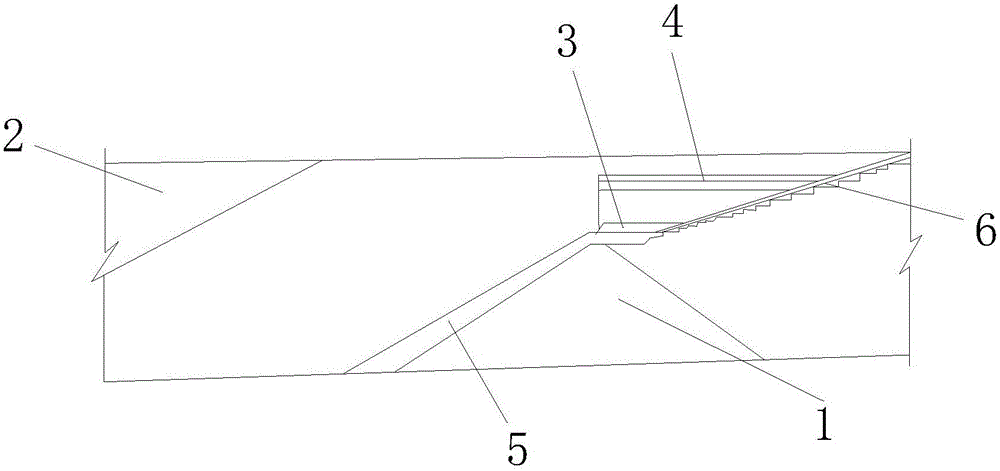

[0033] Such as figure 1 , figure 2 with image 3 The construction method of a tailings pond shown includes building a new tailings pond 2 downstream of the old tailings pond 1, when the water level in the new tailings pond 2 is greater than 7m from the bottom of the old tailings pond 1 , draw ore along the outer slope of the old tailings pond 1 dam to form a slope pressure body, and simultaneously complete the geotextile anti-filter layer 5, water collection corridor 3, and seepage drainage pipe network 4 during the slope pressure process And the embedding of the slope anti-filtration drainage belt 6 until the height of the top of the slope body from the design flood level in the new tailings pond 2 is not less than 10m, so that the new tailings pond 2 and the old tailings pond 1 are isolated, and the specific steps include :

[0034] When the design flood level of the new tailings pond 2 is lower than the height of the initial dam of the old tailings pond 1, select the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com