Intelligent garbage smashing processing system

A garbage crushing and treatment system technology, which is applied in indoor sanitary pipeline installations, water supply installations, buildings, etc., can solve the problems of increasing domestic water consumption, difficult removal of residues, and low effective utilization of garbage processors, and achieves improved garbage disposal. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

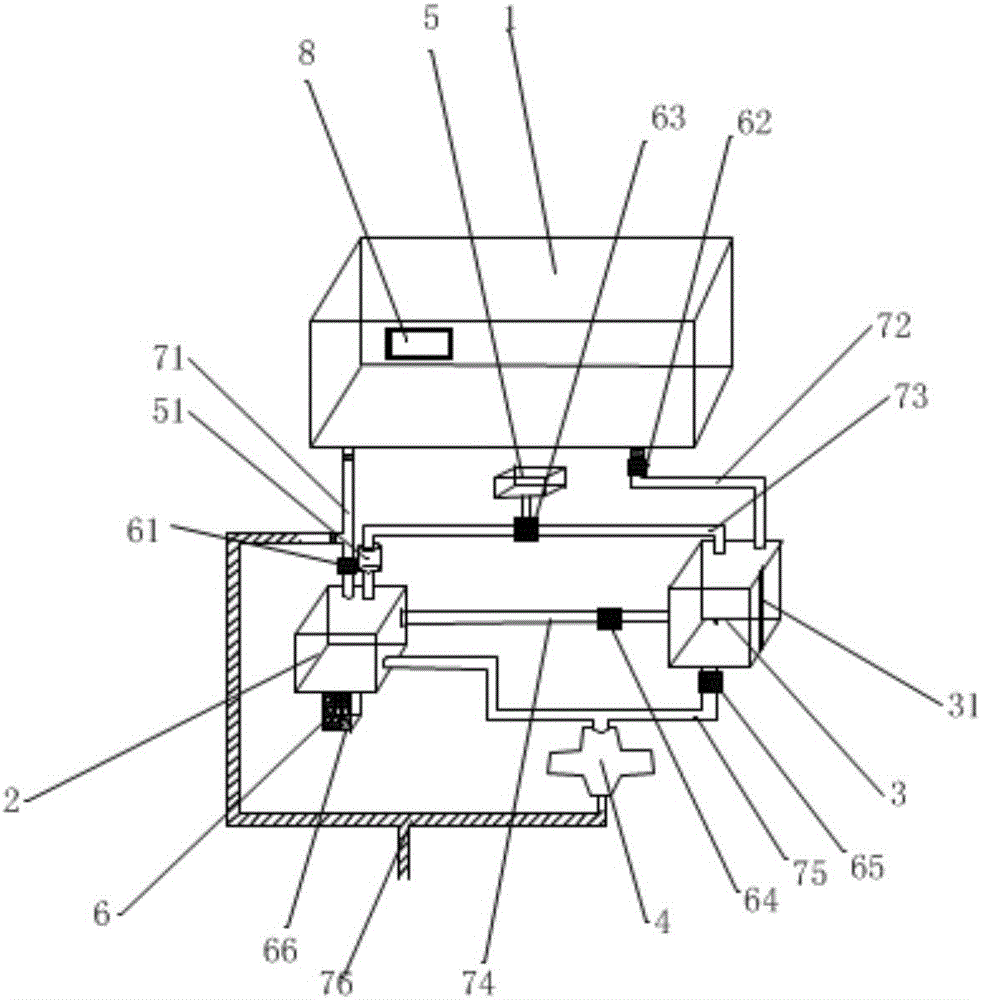

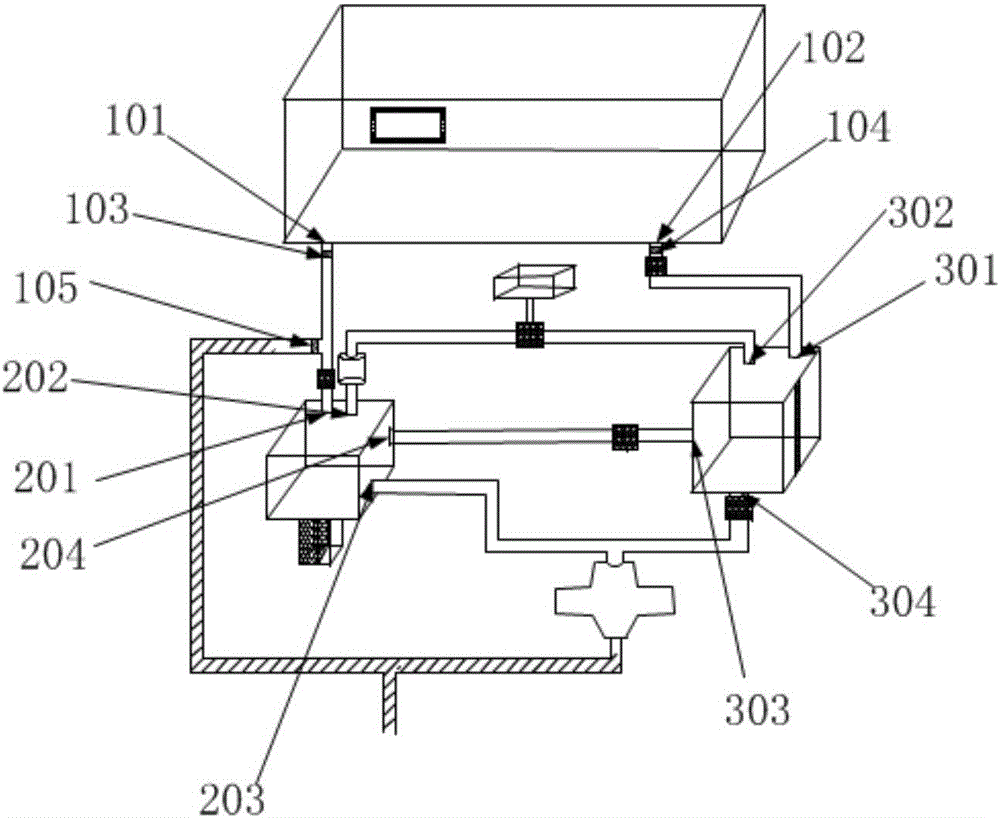

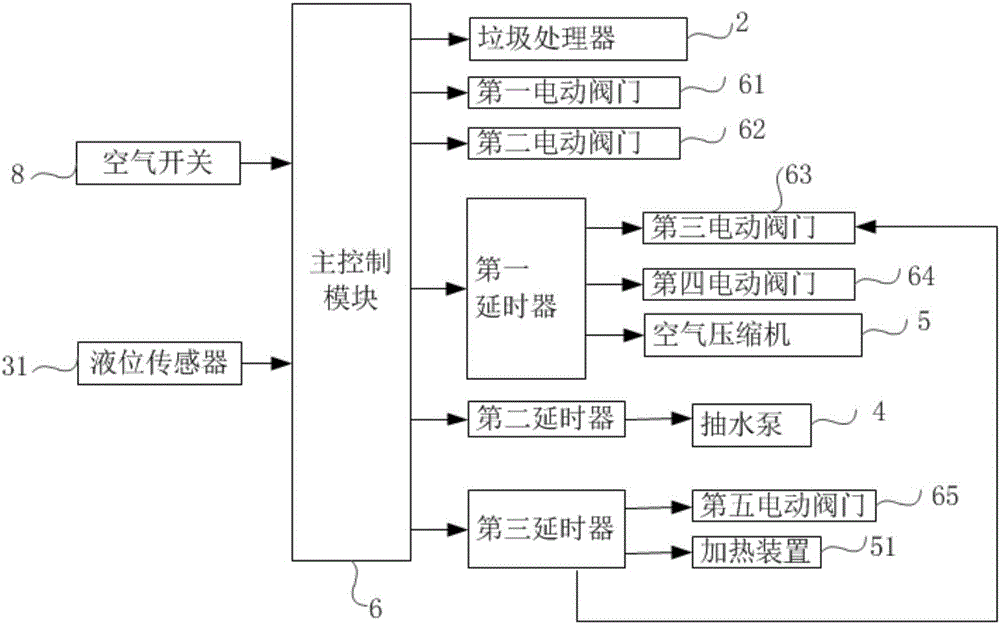

[0039] According to attached figure 1 And attached figure 2 As shown, a kind of intelligent rubbish pulverization processing system comprises water tank 1, garbage disposer 2, sewage pipeline 76, cleaning tank 3, water pump 4, air compressor 5, drainage system and control system; the bottom of described water tank 1 A first drain port 101 and a second drain port 102 are provided, a feed port 201 and a first air intake port 202 are provided on the top of the garbage disposer 2, and a discharge port 203 and a cleaning port 204 are provided on the side wall thereof, And the cleaning port 204 is arranged on the top of the discharge port 203, the top of the cleaning tank 3 is provided with a secondary water inlet 301 and a second air inlet 302, the side wall is provided with a first secondary water outlet 303, and the bottom is provided with a The second outlet 304 for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com