Water storage method at the bottom of open pit or subsidence area in mine reclamation

A technology for open-pit pits and mines, which is applied in the fields of land preparation methods, botanical equipment and methods, and ground mining. It can solve the problems of easy evaporation of square pond water storage, inability to guarantee reclamation water, and no guarantee of water sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

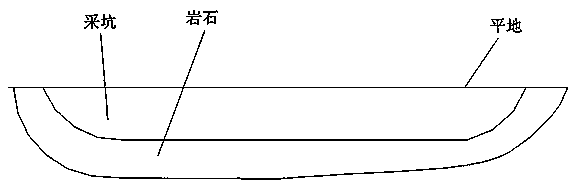

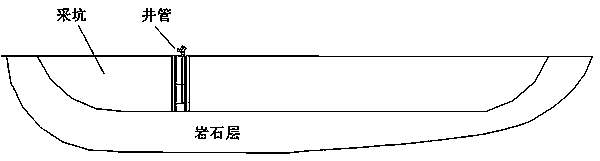

[0022] 1. Select an open pit with a flat surface in an arid or semi-arid area (see figure 1 ); Utilize the non-cracked groove shape at the bottom of the open pit to backfill the waste ore (see Figure 5 ), the backfilled waste ore will fill the closed pit to a height of 40-60cm from the adjacent surface, which is the thickness of the reserved structural surface layer; choose waste ore with a particle size range of 20-50cm to fill the open pit At the bottom of the pit, there is a structure-like underground aquifer through the gap of the waste ore.

[0023] 2. see image 3 , 4 Select the "well position" before filling the waste rock. While filling the waste ore, pre-bury multi-section cast iron well pipes, from the bottom of the pipe to the bottom of the pit. The outer diameter of the cast iron well pipe is 440mm. The pressure is used as the reference, and the anti-oxidation layer 2 is applied; the multi-section cast iron well pipes from the bottom of the pit to the surface a...

Embodiment 2

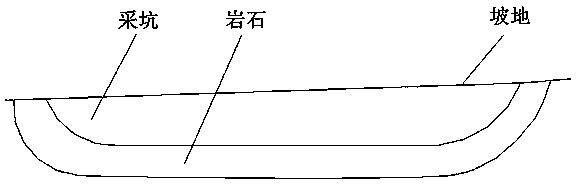

[0028] Select an open pit on a slope in an arid or semi-arid region (see figure 2 ).

[0029] Steps 1, 2, and 3 are as above, and Step 4: After the pit is filled with waste rock, a clay fixed layer 9 is laid on the upper layer with a thickness of 10-20 cm, compacted and fixed, and an iron tailings sand layer is laid with a thickness of 5-10 cm. The uppermost layer is guest soil layer 7, with a thickness of 25-30cm, made of high-quality cultivated land. At the same time, terraces are built to prevent water and soil erosion, and play the role of water storage, soil conservation and production increase. Irrigation facilities adopt drip irrigation or sprinkler irrigation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com