Water-coal-slurry low-nitrogen combustion steam-injection boiler and low-nitrogen combustion mode thereof

A low-nitrogen combustion and steam injection boiler technology, which is applied to combustion equipment, lighting and heating equipment, etc., can solve the problems of affecting combustion efficiency and energy waste, and achieve the effect of suppressing the formation of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

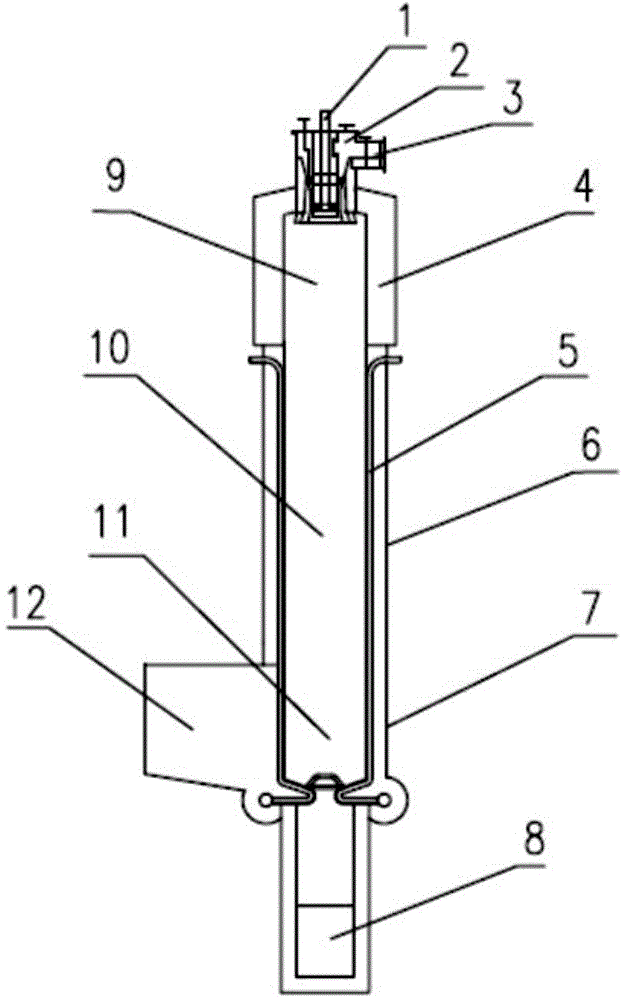

[0020] Attached below figure 1 , to illustrate the specific implementation of the present invention.

[0021] The low-nitrogen combustion method of the coal-water slurry steam injection low-nitrogen boiler includes the low-nitrogen burner of the coal-water slurry, moderate low-oxygen combustion technology, air classification air distribution technology, etc.

[0022] The ignition and stable combustion of coal-water slurry requires a certain heat-insulating area to increase the ambient temperature in the area. The upper half of the modified coal-water-slurry steam-injected low-nitrogen boiler is the heat-insulating area where the heat-insulating layer 4 is installed, and no water-cooled wall is arranged. It is beneficial to the ignition of the coal-water slurry, and the lower half is the heating area where the water-cooled wall pipe 5 is installed around the furnace body. From top to bottom, the furnace is divided into ignition pre-combustion zone 9, stable combustion zone 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com