Biomass comprehensive utilization system and biomass comprehensive utilization method

A biomass and biomass boiler technology, used in biofuels, special forms of dry distillation, gasification processes, etc., can solve problems such as transportation and maintenance supply constraints, low energy density, and difficulty in collection, and achieve high comprehensive utilization value and activity. Good, the effect of suppressing the generation of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

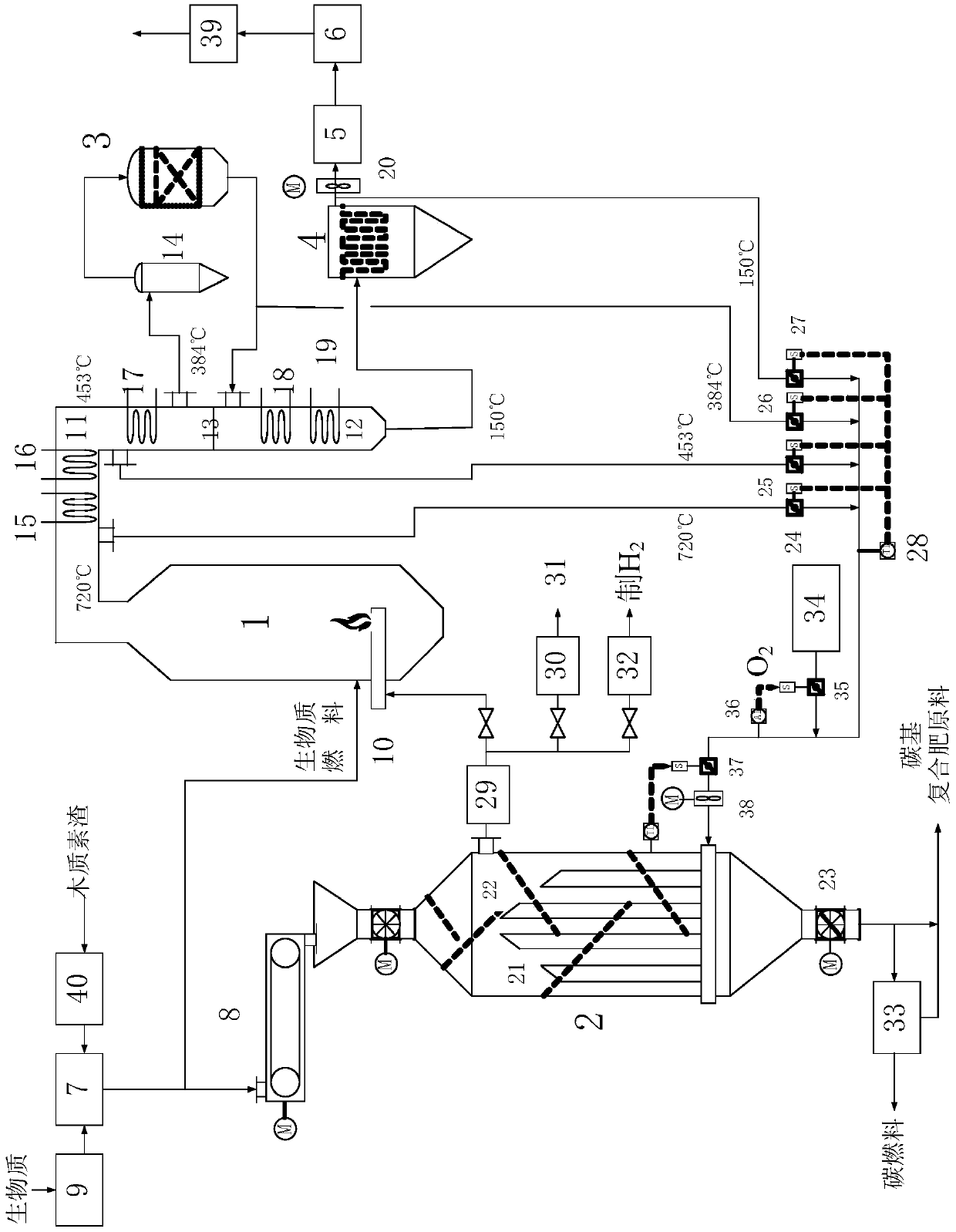

[0102] This embodiment provides a system for comprehensive utilization of biomass, wherein the schematic structural diagram of the system is as figure 1 Shown from figure 1 It can be seen that the system includes crushing equipment 9, drying equipment 40, molding equipment 7, conveying system 8, biomass boiler 1, biomass gasification / carbonization furnace 2, SCR denitrification device 3, and bag dust removal device 4 , Desulfurization device 5 and wet electric dust removal device 6, of which,

[0103] The crushing device 9 is a crushing device for crushing biomass raw materials;

[0104] The molding equipment 7 is a molding equipment for compression molding the pulverized biomass raw material;

[0105] When the biomass raw material is lignin residue, the drying device 40 is a drying device for drying the lignin residue;

[0106] The conveying system 8 is a conveying system for conveying the compressed and molded biomass to the biomass gasification / carbonization furnace 2;

[0107] Th...

Embodiment 2

[0122] This embodiment provides a method for comprehensive utilization of biomass, which is implemented by adopting the system for comprehensive utilization of biomass provided in Example 1. The method includes the following steps:

[0123] (1) After the used biomass is processed for impurity removal, coarse crushing, pulverization, etc., according to the desired shape of the biomass after compression molding, different molding machines are selected for compression molding to obtain rods, pellets, etc. Type or hollow rod type biomass fuel block;

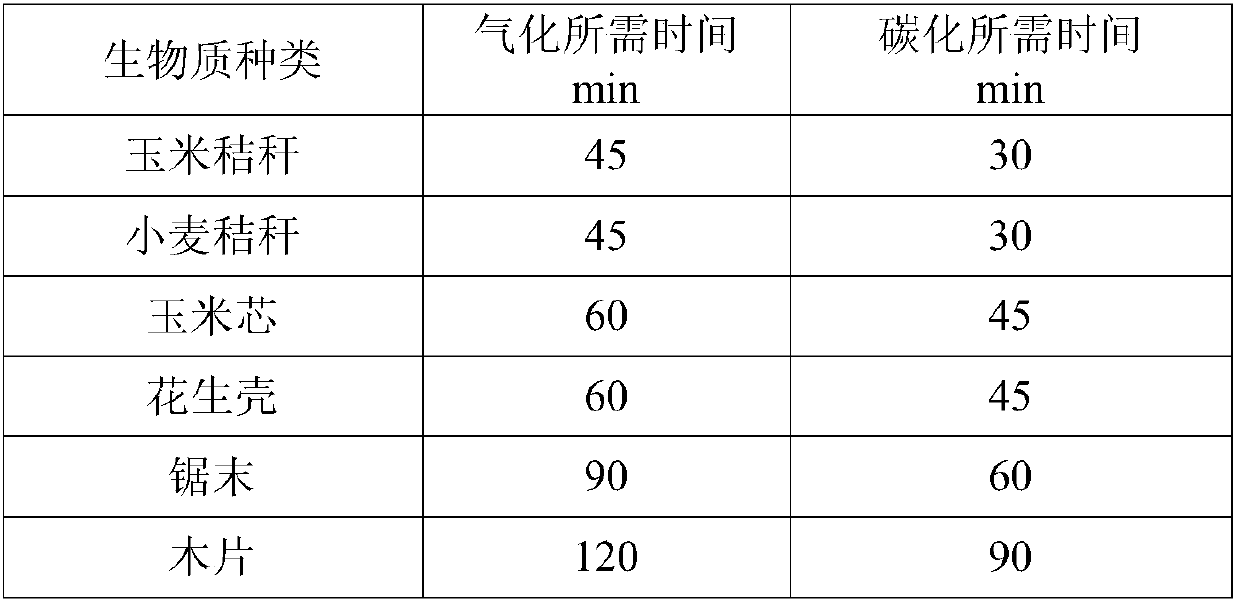

[0124] Wherein, the biomass includes, but is not limited to, corn cobs, corn stalks, wheat stalks, straw, branches, tree trunks, sawdust, peanut shells, and lignin residue; if lignin residue is selected, the lignin residue is required before compression Carry out preliminary drying (the flue gas of biomass power plant can be used for preliminary drying) to control its moisture content to 10-20%;

[0125] (2) Burn a part of the biomass fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com