Rolling bearing fault identification and trend prediction method

A rolling bearing and fault identification technology, applied in mechanical bearing testing, etc., can solve problems such as weak early fault features, submerged characteristic signals, and low signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

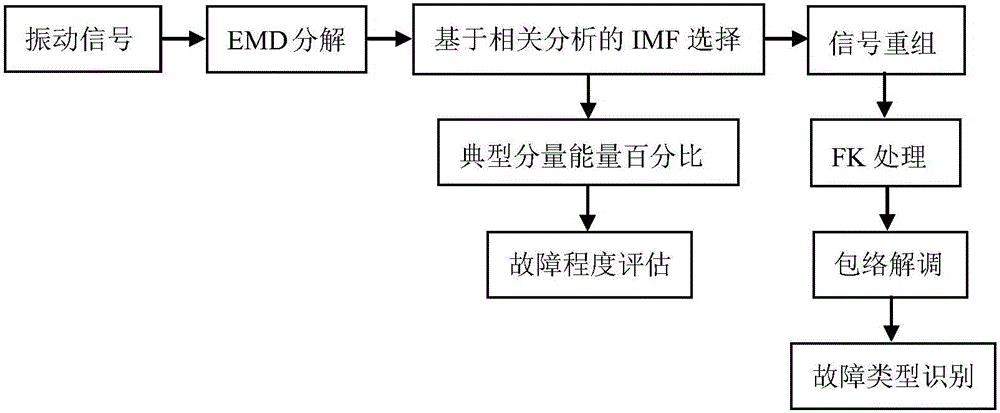

[0070] The present invention is a bearing fault diagnosis algorithm, which includes two parts: fault type identification and fault degree evaluation. The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0071] Take SKF's 6205-2RS deep groove ball bearing in part of the experimental data of the bearing vibration database of Case Western Reserve University in the United States as an example.

[0072] The overall step flow chart of the rolling bearing fault diagnosis method disclosed in the present invention is as follows: figure 1 As shown, the specific steps are as follows:

[0073] S1. Select the vibration signal

[0074] Select the vibration signal of the bearing under normal and different degrees (0.1778 mm, 0.3556 mm, 0.5332 mm) of single-point inner ring fault, outer ring fault and rolling element fault as the original signal x(t).

[0075] S2. Using EMD to decompose the original signal

[0076] Empirical mode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com