Quantitative analysis method for acrylic fibers

A technology for quantitative analysis of acrylic fibers, applied in the field of quantitative analysis of acrylic fibers, can solve problems such as large limitations and unsuitable quantitative analysis of acrylic fiber mixtures, and achieve high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

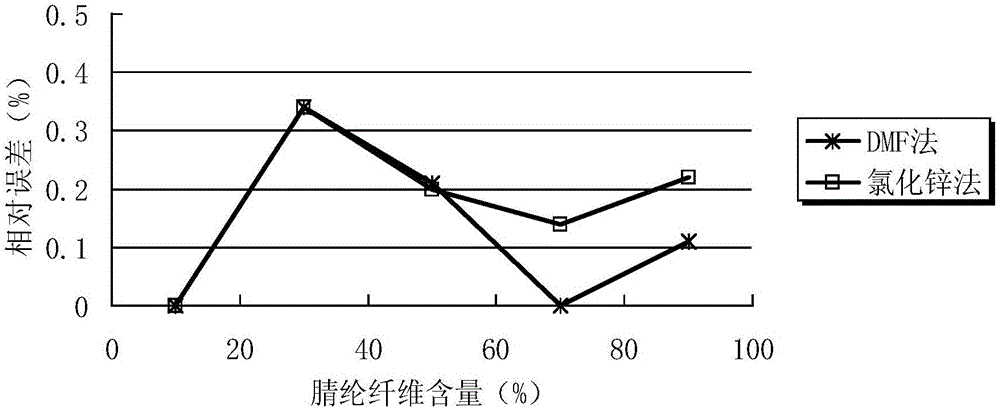

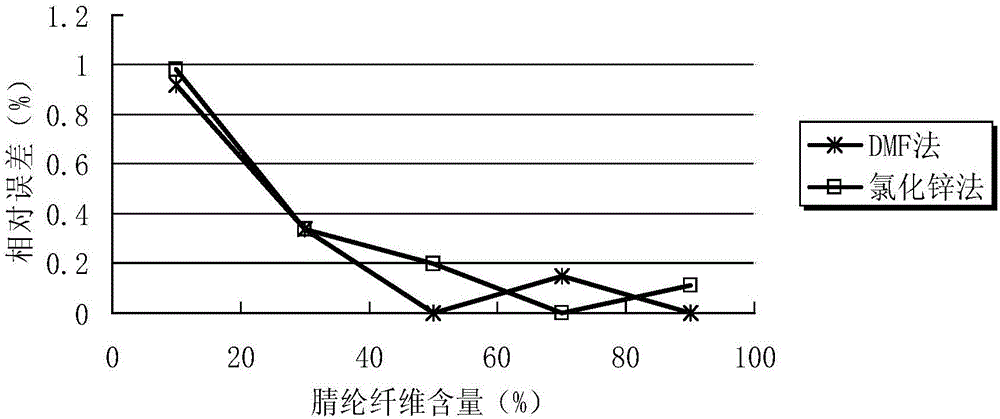

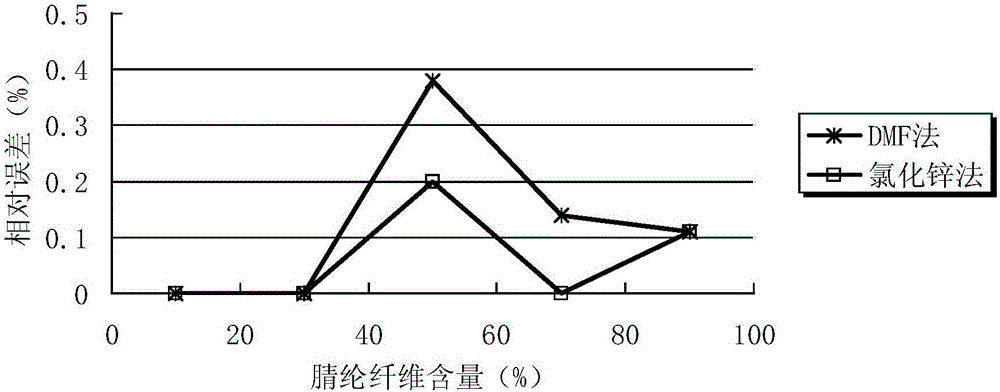

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment;

[0038] This embodiment provides a kind of quantitative analysis method of acrylic fiber, is used for the quantitative analysis of acrylic fiber and polyamide fiber, acrylic fiber and polyester fiber, acrylic fiber and viscose, acrylic fiber and tencel fiber blending quantitative analysis, comprises the following steps:

[0039] a) Put the acrylic fiber blended sample into a constant temperature oven to dry, cool, and then weigh. In one embodiment, put the acrylic fiber blended sample into a weighing bottle and dry it in a constant temperature oven at (105±3)°C. After two hours, take out the weighing bottle and put it in a desiccator. Cool for 30 minutes; then weigh the acrylic fiber blended sample.

[0040] b) Put the acrylic fiber blended sample into the Erlenmeyer flask, add 100mL of 6.5mol / L zinc chloride solution per gram of the sample, plug t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com