Current detecting circuit based on bi-directional saturation current sensor and driving method thereof

A technology of current detection circuit and current sensor, which is applied in the direction of measuring current/voltage, only measuring current, instruments, etc., can solve the problem that the detection current temperature has a large influence and it is difficult to meet the reliable high-temperature working ability and high-precision isolation of SiC-based high-temperature resistant converters. And AC/DC detection ability, Hall element is difficult to withstand high temperature environment above 200 ℃, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

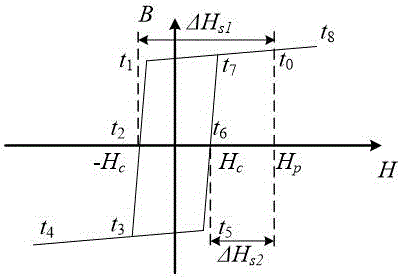

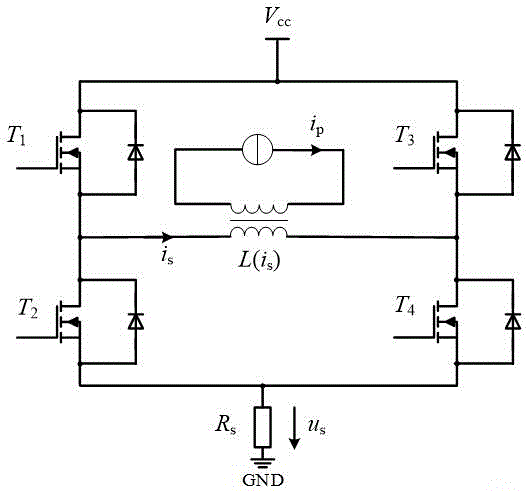

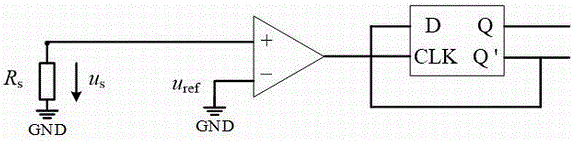

[0038] The operating principle of the circuit of the present invention is: the primary side current i p and primary magnetic field strength H p The relationship is: H p =(i p ·N p ) / l m ; H-bridge power device T 1 , T 4 Secondary current i at turn-on s1 , T 2 , T 3 Secondary current i at turn-on s2 The relationship with the magnetic field strength of the secondary side is: ΔH s1 =(i s1 ·N s ) / l m , ΔH s2 =(i s2 ·N s ) / l m . It can be seen from the hysteresis loop of the secondary side of the current sensor: H p =(ΔH 1 +ΔH 2 ) / 2. Therefore, the source current to be measured can be represented by two secondary currents: i p =N s (i s1 + i s2 ) / 2N p .

[0039] From the hysteresis loop of the secondary side of the current sensor, it can be seen that the remanence of the positive half axis and the negative half axis are H c and -H c . When the temperature rises, the size of the positive and negative remanence will drift with temperature, but the magnit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com