A multi-process accumulative error control method for large-scale curved circular steel pipes in space

A technology of accumulative error and control method, which is applied in the direction of instruments, geometric CAD, calculation, etc., can solve problems affecting space bending pipeline, residual stress, increasing time cost and labor cost, etc., to reduce operation difficulty, realize control error, The effect of reducing the difficulty of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

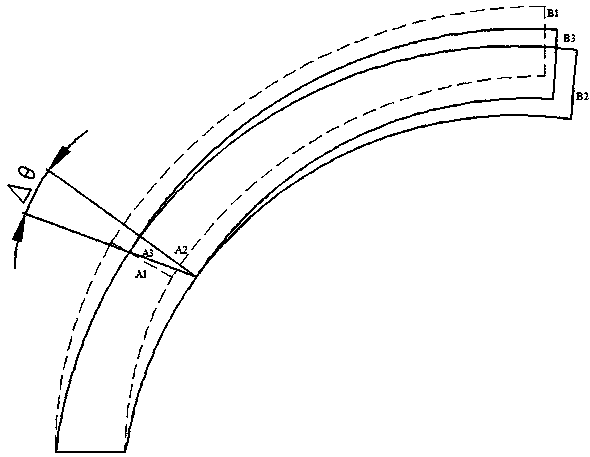

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0045] The manufacturing method of space bending round steel pipe is carried out according to the following steps:

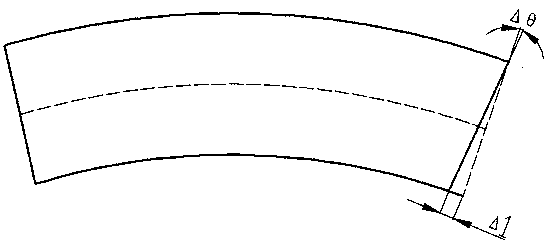

[0046] The first step of lofting: On the basis of computer modeling, the actual shape of the component is intercepted from the model, and the stakeout is carried out with the help of the computer. The divided components are taken out separately on the computer, and the chord length and sagittal height are measured as the processing values. After the lofting inspection is qualified, make the necessary angles, notches, production templates and tire frame templates according to the process requirements.

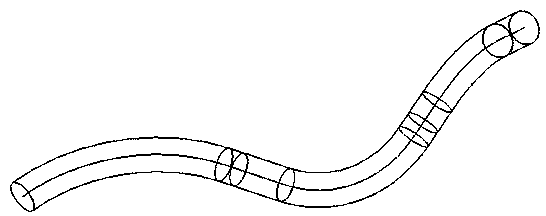

[0047] The second step of bending and forming: use a large hydraulic press to perform mechanical cold processing on a special mold or use an intermediate frequency pipe bending machine for thermal processing to process and shape each sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com