Integrated sheathing method for powder metallurgy plate

A powder metallurgy and wrapping technology is applied in the field of integrated wrapping of powder metallurgy sheets, which can solve the problems of low bonding strength and cumbersome process, and achieve the effects of good effect, simple process and strong designability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

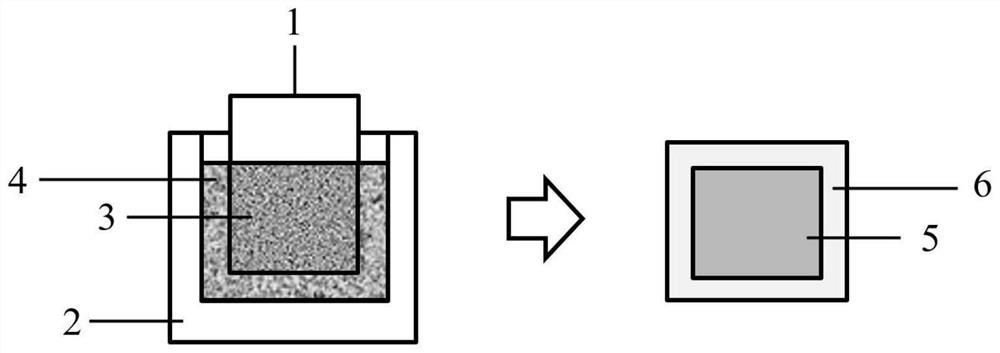

[0027] Embodiment 1: The integrated wrapping method of the powder metallurgy sheet in this embodiment is specifically carried out according to the following steps:

[0028] 1. Weigh the powder metallurgy billet powder and the wrapping material powder;

[0029] 2. Fill the bottom of the overall mold with the powder of the packaging material and shake it;

[0030] 3. Place the separating mold along the central axis of the overall mold on the upper part of the packaged material powder after vibration;

[0031] 4. Fill the powder metallurgy billet powder into the separation mold, and then fill the gap between the overall mold and the separation mold with the powder of the packaging material, and the whole is shaken;

[0032] 5. Take out the separation mold vertically upward, and perform the overall vibration again;

[0033] 6. Fill the powder of the coating material on the top of all the powders for capping, and then conduct the overall powder compaction to obtain a fully enclos...

specific Embodiment approach 2

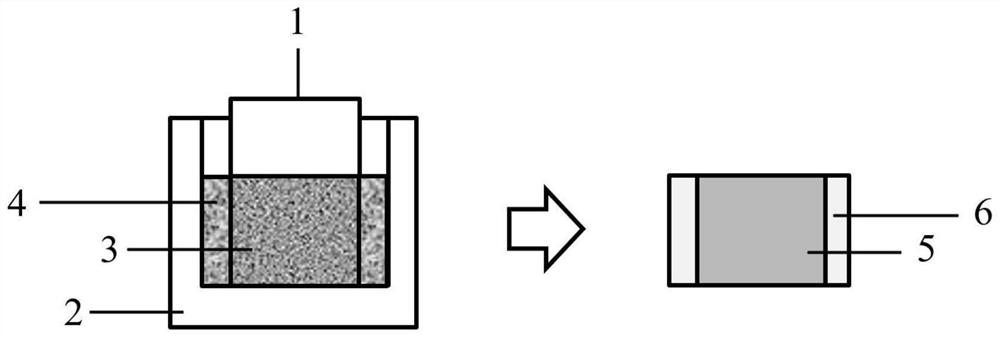

[0035] Specific embodiment 2: The integrated wrapping method of the powder metallurgy sheet in this embodiment is specifically carried out according to the following steps:

[0036] 1. Weigh the powder metallurgy billet powder and the wrapping material powder;

[0037] 2. Place the separating mold on the bottom surface of the overall mold along the central axis of the overall mold;

[0038] 3. Fill the powder metallurgy billet powder into the separation mold, and then fill the gap between the overall mold and the separation mold with the powder of the packaging material, and the whole is shaken;

[0039] 4. Take out the separating mold vertically upwards, and perform the overall vibration again to obtain the semi-closed envelope powder;

[0040] 5. Perform powder metallurgy, demoulding, and machining on the semi-closed envelope powder, and finally obtain an integrated closed envelope component of the powder metallurgy plate.

specific Embodiment approach 3

[0041] Embodiment 3: This embodiment differs from Embodiment 1 or 2 in that: the integral mold is a steel mold or a graphite mold, and the partition mold is an acrylic mold or a metal mold. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com