A high-temperature heating device applied to a small mocvd system

A high-temperature heating and small-scale technology, applied in the field of high-temperature heating devices, can solve problems affecting the life and stability of heating equipment, oxidation or corrosion of heating elements, adverse effects of material growth, etc., and achieve low processing technology difficulty, prevent oxidation or corrosion, Effects that are easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

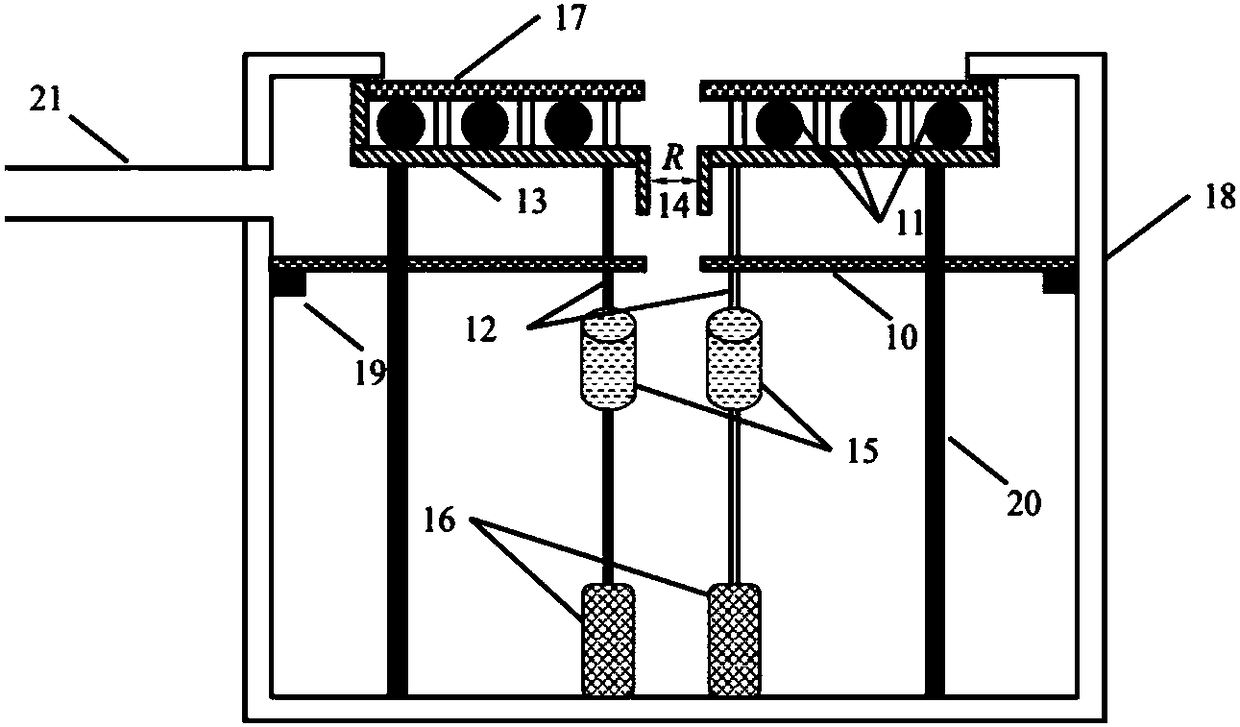

[0030] Such as figure 1 As shown, a high-temperature heating device applied to a small-scale MOCVD system according to the present invention includes a heating body in which a heating resistance wire 11, an electrode connecting wire 12 and an electric hob 13 are arranged. In this embodiment, the resistance wire The material is tungsten wire, the electric hob is 95 porcelain, the shape is circular, the diameter is 10cm, and it is supported by the support rod 20 fixed on the base inside the cavity. There is a hole 14 (marked with diameter R at the same time) in the middle of the electric stove, and the diameter of the hole is 1.2cm, which can be used for the rotation shaft to pass through. The upper part of the electrode connection line first passes through a stainless steel sleeve with a length of 2cm and a diameter of 0.4cm, and welds them together. The outside of the stainless steel sleeve is protected by a ceramic tube 15 to prevent short circuit. The lower part is welded to...

Embodiment 2

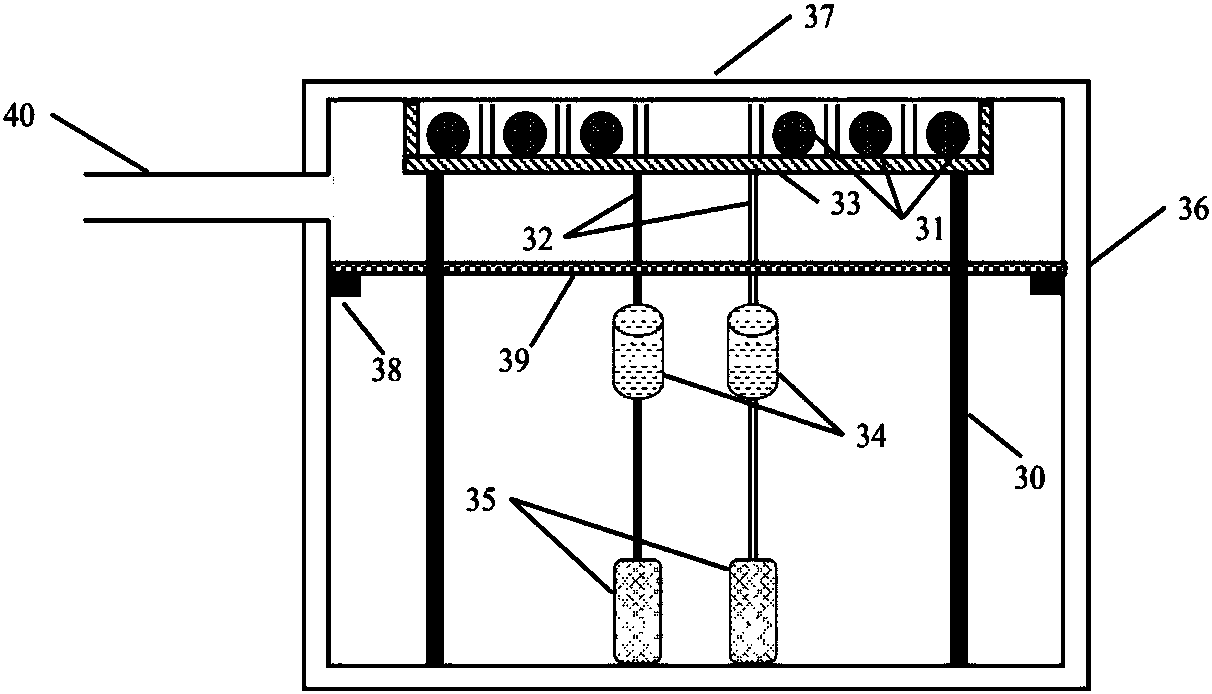

[0033] Such as image 3 As shown, a high-temperature heating device of a small-sized MOCVD system according to the present invention includes a heating body in which a heating resistance wire 31, an electrode connecting wire 32, and an electric hob 33 are fixed on a base inside the cavity. Supported by the support rod 30. In this embodiment, the material of the resistance wire is tungsten wire, the electric hob is 95 porcelain, the shape is circular, and the diameter is 8cm. The upper part of the electrode lead is first passed through a stainless steel sleeve with a length of 3 cm and a diameter of 0.4 cm, and welded together. The stainless steel sleeve is protected by a ceramic tube 34 outside to prevent short circuits. The lower part is welded together with a metal screw whose diameter is the same as that of stainless steel. The bushings are equivalent, and are closely connected with the terminal 35 through nuts to ensure good contact of the electrodes. The exterior of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com