A kind of processing method of air heater injector

An air heater and processing method technology, applied in the field of air heaters, can solve problems such as gas and fuel atomization of easy-to-burn equipment, uneven fuel atomization, damage to heating equipment, etc., achieve good swirl and atomization effects, and reduce processing technology Difficulty, effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

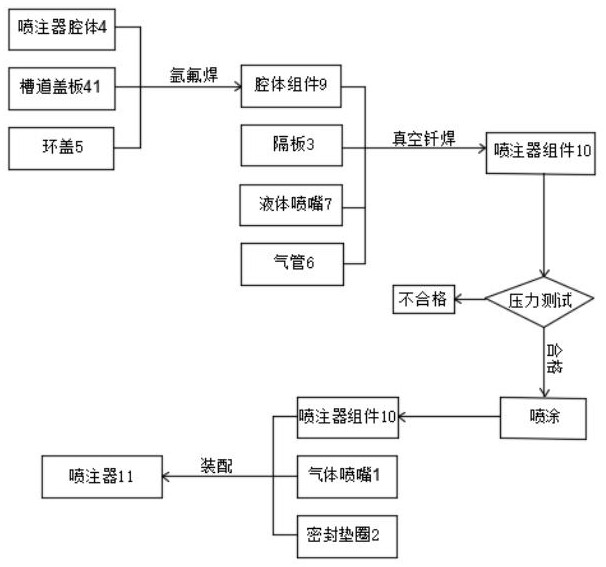

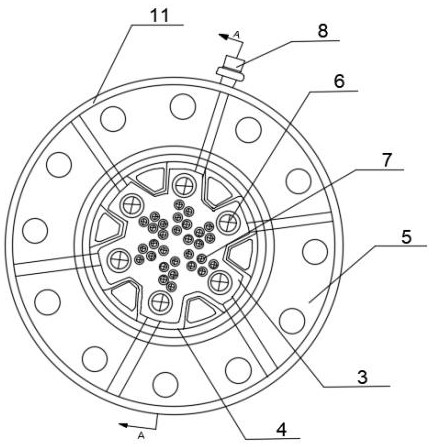

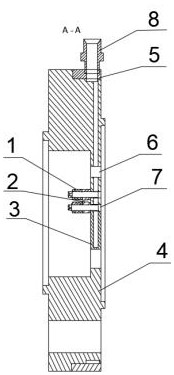

[0051] using as image 3In the method shown, a square groove is milled on the injector cavity 4 by milling, and then the channel cover 41 is welded on the square groove by argon arc welding to form a square hole.

[0052] using as Figure 4 In the method shown, a sinking table 42 is washed and processed on the partition plate 3 by washing and processing. The size of the sinking table is 14 mm in diameter and 1 mm in height. The solder blocks the liquid flow hole during soldering.

[0053] The liquid nozzle 7 and the gas pipe 6 need to pass through the holes of the injector cavity 4 and the partition plate 3 at the same time to be matched on the machining center to reach the position of the hole between the two parts of the injector cavity 4 and the partition plate 3 In the same way, it can reduce the difficulty of assembly and improve the quality of the brazing seam.

[0054] The ring cover 5 is welded on the injector cavity 4 by argon arc welding to form a cavity assembly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com