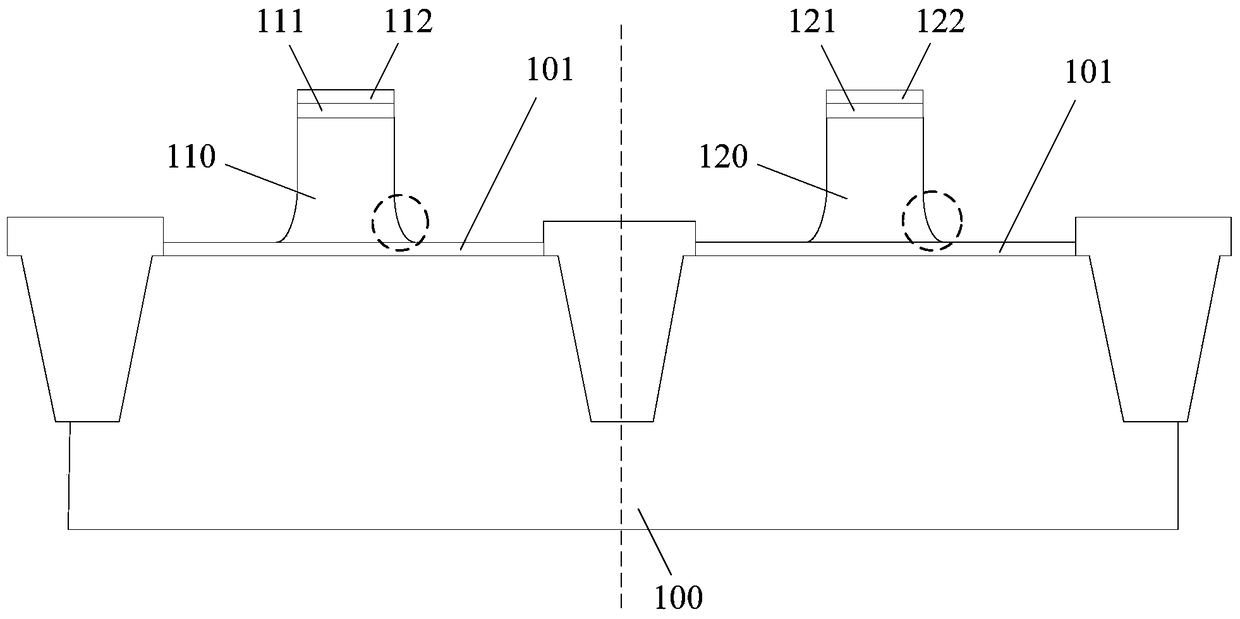

How to form a mos transistor

A MOS transistor and layer-forming technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of MOS transistor carrier mobility decrease, device performance impact, etc., to prevent metal diffusion, improve performance, and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

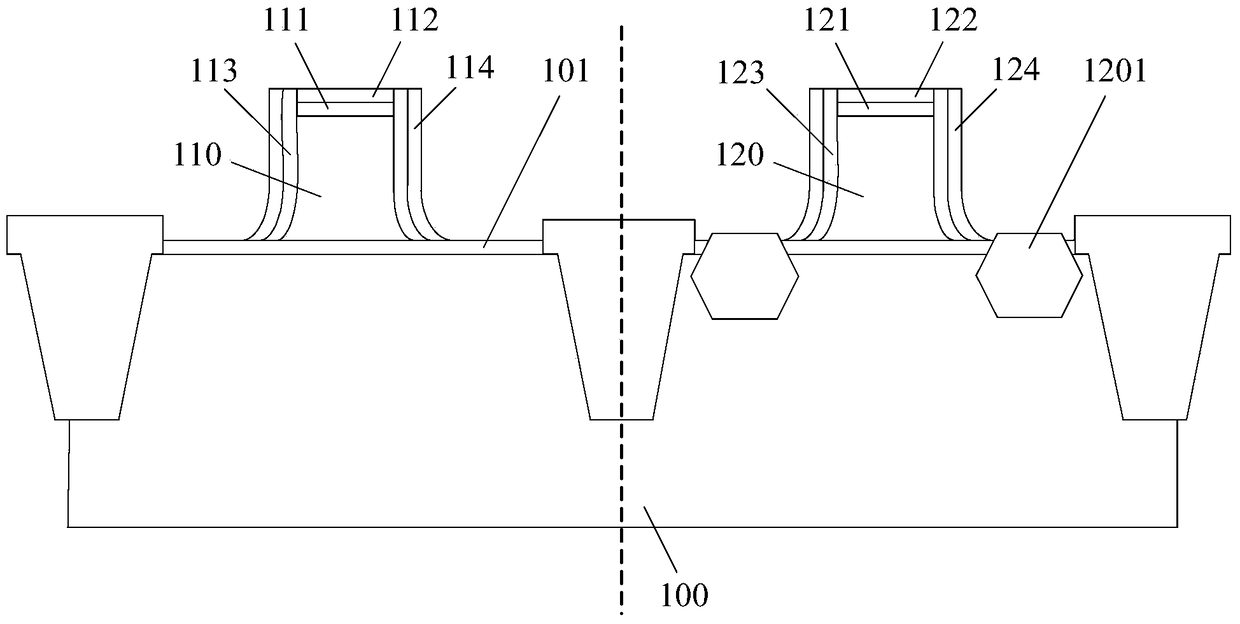

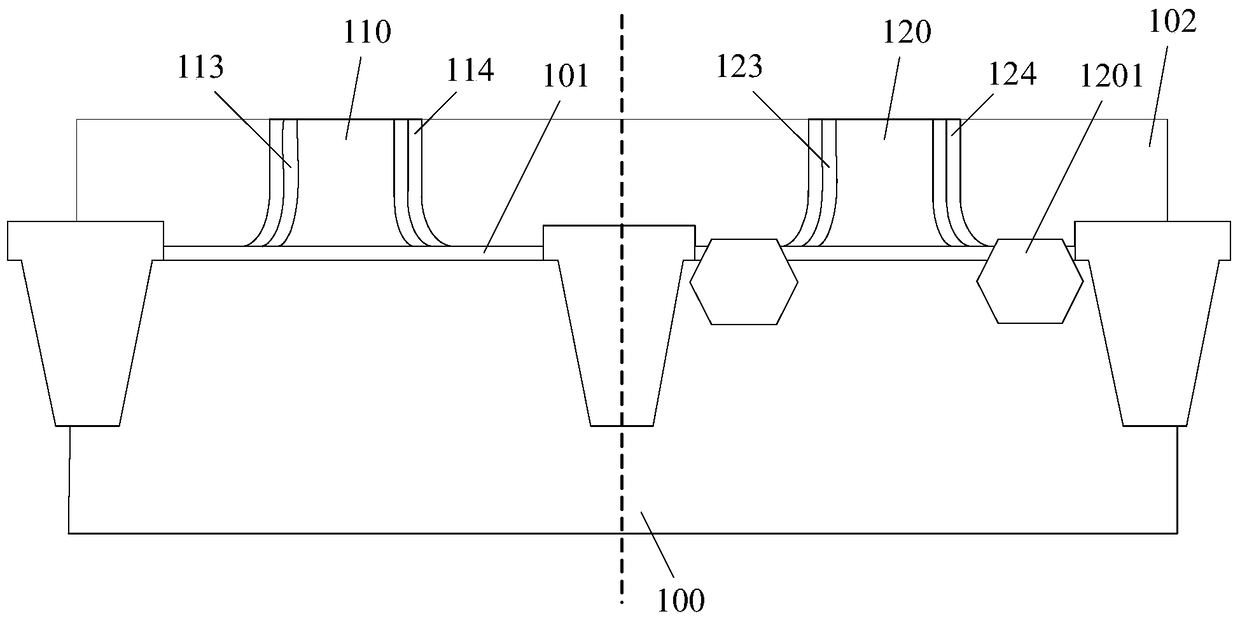

Embodiment Construction

[0031] The inventors found that the aluminum in the metal gate has two diffusion routes, one is to diffuse downward through the bottom of the metal aluminum gate (that is, it diffuses downward through the top of the channel region), and the other is to diffuse through both sides of the metal aluminum gate. diffusion. Although, in the existing MOS transistor formation method, a diffusion barrier layer is first formed in the groove for filling the metal gate before making the metal gate to prevent aluminum from diffusing, however, the diffusion barrier layer produced by the existing method usually There will be a large shrinkage stress (especially the diffusion barrier layer formed by physical vapor deposition method, the stress is relatively large), under the action of stress, the diffusion barrier layer will appear thick at the center of the bottom of the groove, and the two sides of the groove will be thick. In the case where the thickness of the side bottom corner part gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com