Memory component and manufacturing method thereof

A technology for memory elements and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., capable of solving problems such as high contact resistance and limited process margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

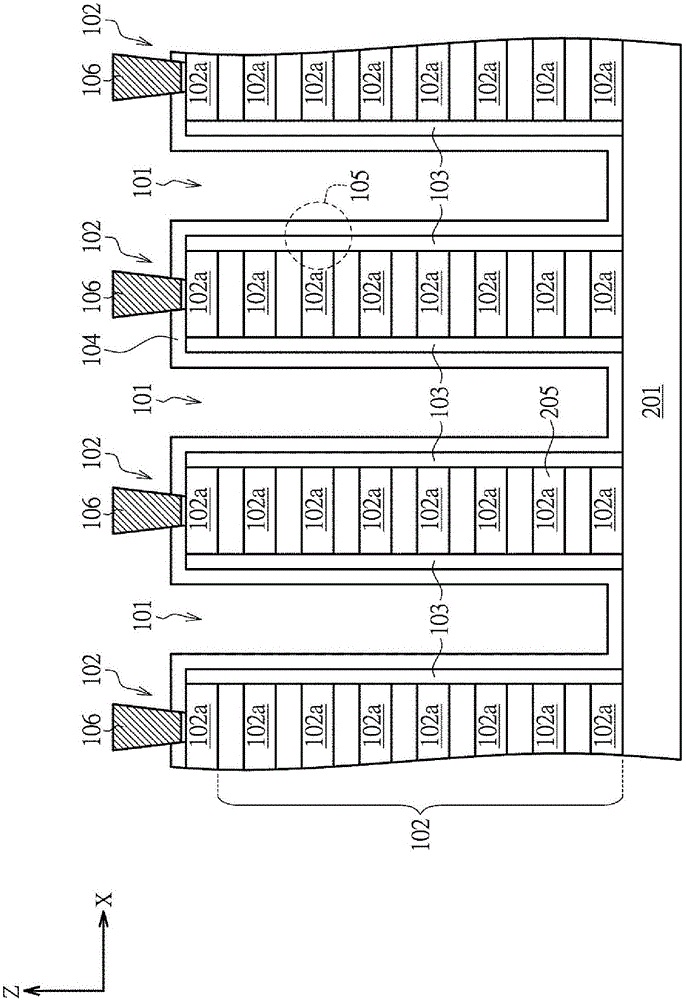

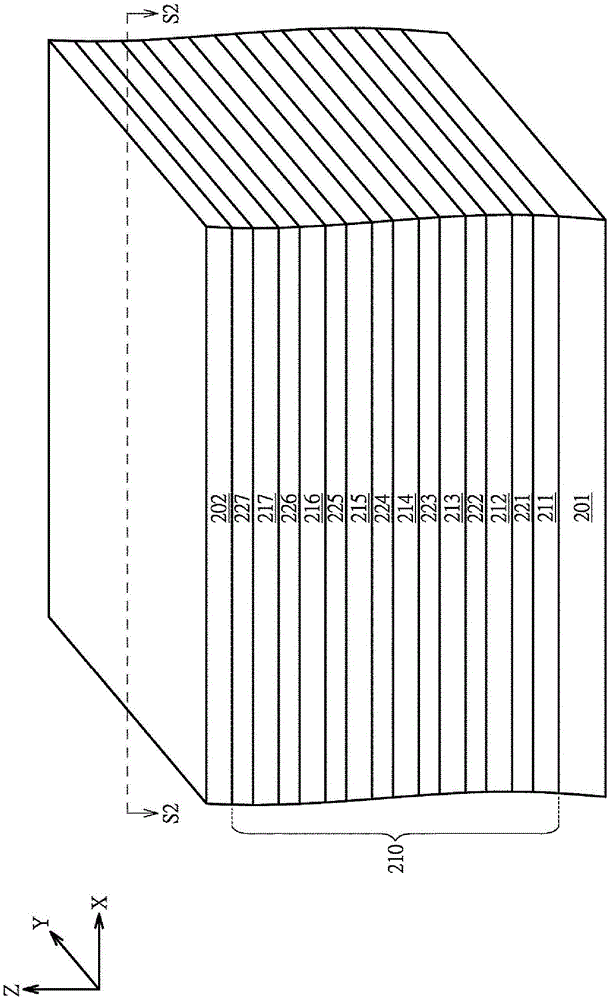

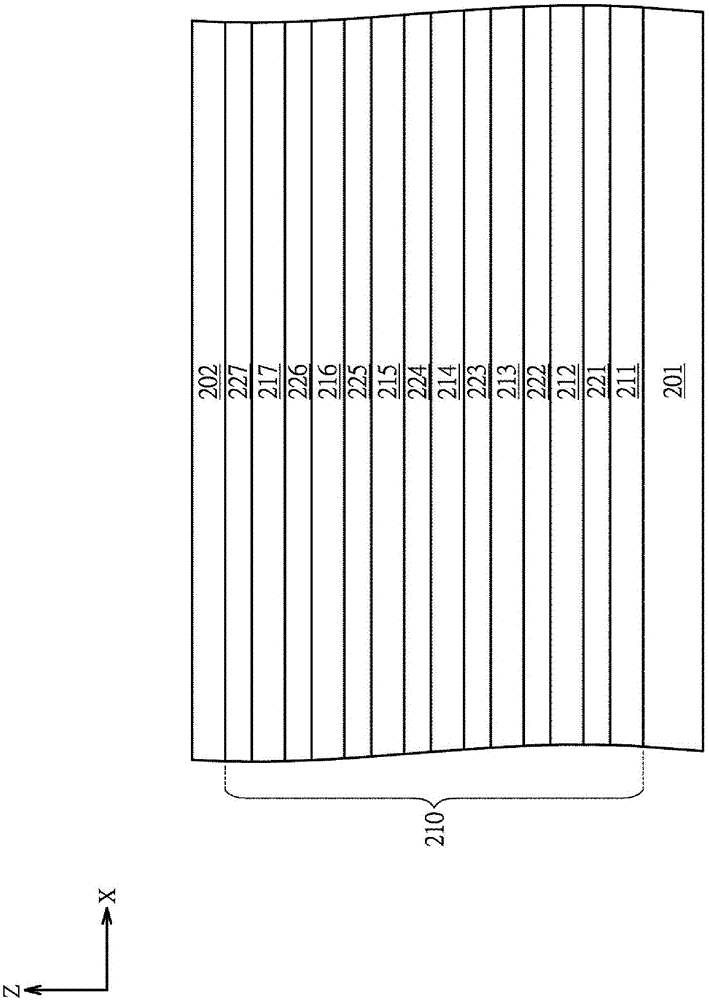

[0033] The invention provides a three-dimensional memory element and its manufacturing method, which can provide a large process margin for the three-dimensional memory element to form a metal contact structure, and at the same time reduce the contact resistance of the metal contact structure. In order to make the above-mentioned embodiments and other objects, features and advantages of the present invention more comprehensible, the digital 3D memory device and its manufacturing method are specifically cited below as preferred embodiments and described in detail with the accompanying drawings.

[0034] However, it must be noted that these specific implementation cases and methods are not intended to limit the present invention. The invention can still be implemented with other features, elements, methods and parameters. The proposal of the preferred embodiment is only used to illustrate the technical characteristics of the present invention, and is not used to limit the patent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com