Optical fiber gas cascaded Raman laser capable of realizing 3-5-micron band tuning

A Raman laser and Raman laser technology, applied in the field of lasers, can solve the problem of low Raman conversion efficiency, achieve high Raman conversion efficiency, low loss, and improve conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

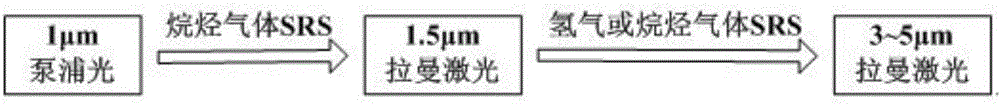

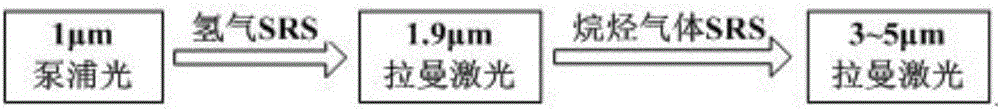

[0043] As shown in Figure 3(a), a fiber gas cascade Raman laser that can be tuned in the 3-5 μm band includes a pump laser 300, a first-stage Raman laser generator and a second-stage Raman laser generator , wherein both the first-stage Raman laser generating device and the second-stage Raman laser generating device are ring-cavity feedback structure laser generating devices. The first-stage gas Raman laser generating device converts the 1 μm pump laser 301 generated by the pump laser 300 into the first-stage Raman scattered laser 320, and the first-stage Raman scattered laser 320 is in the 1.5 μm or 2 μm wave band laser. The first-level Raman scattering laser 320 is used as the pumping laser of the second-level Raman laser generating device. The first-stage Raman laser generating device includes a first high reflection mirror 302, a second high reflection mirror 303, a first half-wave plate 304, a 1# polarizing beam splitter prism 305, a second half-wave plate 306, 1# coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com