Method for reducing vomitoxin of wheat bran through extrusion

A technology of extruding and puffing wheat bran, which is applied in food mechanical processing, food science, application, etc., to achieve the effect of high dietary fiber content, simple operation steps, and low vomitoxin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

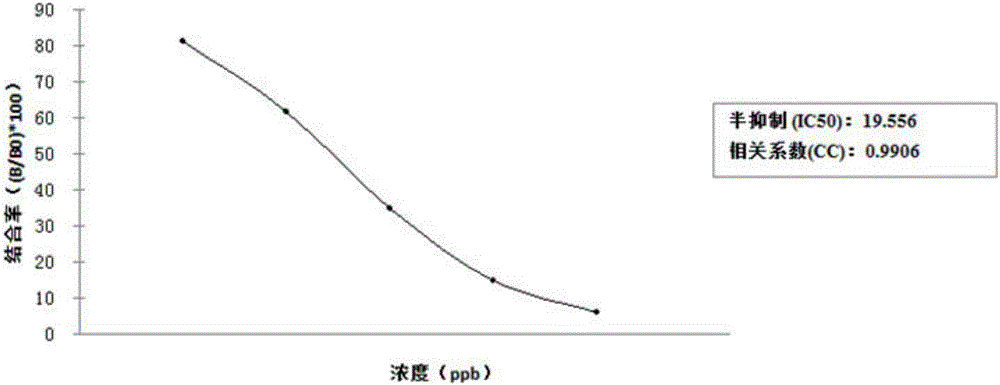

Image

Examples

Embodiment 1

[0047] A method for reducing wheat bran vomiting toxin by extrusion and puffing includes the following steps:

[0048] (1) Add 5 kg of wheat bran to 15 kg of water, stir evenly, add solid sodium hydroxide to adjust the pH to 10.23, soak for 20-30 minutes, press filter to obtain 9.2 kg of product;

[0049] (2) Put the 9.2kg product obtained in step (1) in a boiling dryer, and control the air volume at 1500m 3 / h, the inlet temperature is 80℃, and the drying is 15min, to obtain 5.2kg of dried wheat bran with a moisture content of 31.5%;

[0050] (3) Mix the dried wheat bran obtained in step (2) with 1.8kg starch uniformly;

[0051] (4) Put the wheat bran and starch mixture obtained in step (3) in an extruder, the screw speed is 10r / min, the extrusion temperature is 160℃, and the puffing detoxification process is performed to obtain wheat bran and Starch puffed product, and then put the wheat bran and starch puffed product in a pulverizer to smash to obtain 5.1 kg of detoxified wheat bra...

Embodiment 2

[0055] A method for reducing wheat bran vomiting toxin by extrusion and puffing includes the following steps:

[0056] (1) Add 5 kg of wheat bran to 15 kg of water, stir evenly, add solid sodium hydroxide to adjust the pH to 11.02, soak for 20-30 minutes, press filter to obtain 9.1 kg of product;

[0057] (2) Put the 9.1kg product obtained in step (1) in a boiling dryer, and control the air volume at 1500m 3 / h, the inlet temperature is 80℃, and the drying time is 15min, to obtain 5.1kg of dried wheat bran with a moisture content of 32.3%;

[0058] (3) Mix the dried wheat bran obtained in step (2) with 1.9kg starch uniformly;

[0059] (4) Put the wheat bran and starch mixture obtained in step (3) in an extruder, the screw speed is 10r / min, the extrusion temperature is 180℃, and the puffing and detoxification process is performed to obtain wheat bran and Starch puffed product, and then put the wheat bran and starch puffed product in a pulverizer to pulverize to obtain 4.95 kg of detoxi...

Embodiment 3

[0063] A method for reducing wheat bran vomiting toxin by extrusion and puffing includes the following steps:

[0064] (1) Add 5 kg of wheat bran to 17 kg of water, stir evenly, add solid sodium hydroxide to adjust the pH to 10.55, soak for 20-30 min, press filter to obtain 9.2 kg of product;

[0065] (2) Put the 9.2kg product obtained in step (1) in a boiling dryer, and control the air volume at 1500m 3 / h, the inlet air temperature is 80℃, and the drying time is 15min to obtain 5.3kg of dried wheat bran with a moisture content of 34.1%;

[0066] (3) Mix the dried wheat bran obtained in step (2) with 1.6kg starch uniformly;

[0067] (4) Put the wheat bran and starch mixture obtained in step (3) in an extruder, the screw speed is 15r / min, the extrusion temperature is 170℃, and the puffing and detoxification process is performed to obtain wheat bran and Starch puffed product, and then put the wheat bran and starch puffed product in a pulverizer to smash to obtain 5.1 kg of detoxified w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com