Processing and screening equipment for multi-flavor dried sweet potatoes, with heat-insulating and mixing mechanism

A screening device and sweet potato drying technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problem that the mixing amount cannot reach the mixing amount, and achieve the effects of improving efficiency, simple structure, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

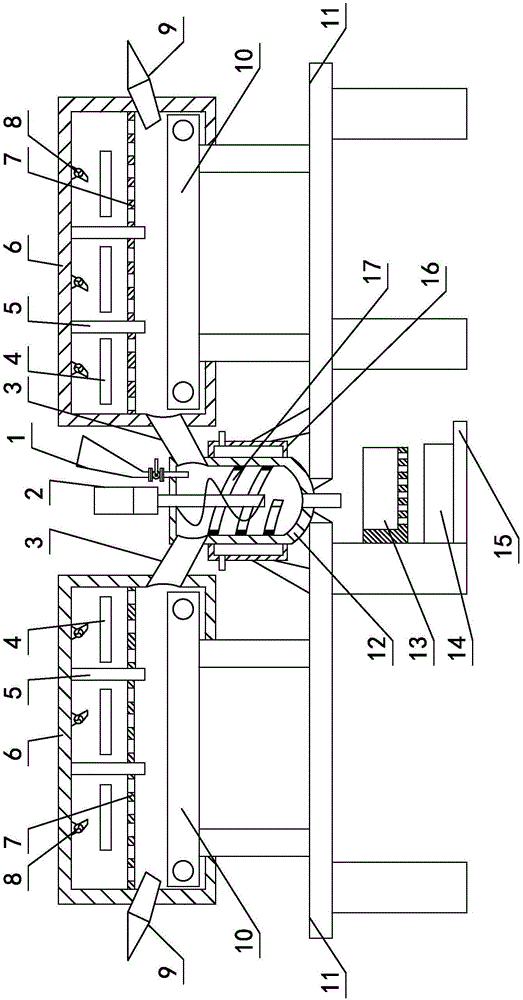

[0022] like figure 1 As shown, the multi-flavor sweet potato dry processing and screening device with heat preservation and mixing mechanism includes a mixing tank 12, an agitator 2 is installed on the mixing tank 12, a workbench 11 and a heating box 6 are arranged on the left and right sides of the mixing tank 12, and the working A high-temperature-resistant belt conveyor 10 is horizontally installed on the platform 11. The conveying part of the belt conveyor 10 is arranged in the heating box 6, and the side wall of the heating box 6 away from the mixing tank 12 is provided with a feed inlet 9. The side wall of the heating box 6 near the mixing tank 12 is provided with a discharge port 3, and the upper half of the heating box 6 is sequentially provided with two partitions 5 from left to right. The upper half is divided into three heating zones with different temperatures, and an electric heater 4 for individually controlling the temperature is installed in each heating zone, ...

Embodiment 2

[0026] Further change on the basis of Embodiment 1, the distance between the lower end of the partition 5 and the belt conveyor 10 becomes 70mm; the thickness of the partition 5 becomes 30mm; the thickness of the second insulation layer becomes 50mm. Others are the same as embodiment one.

Embodiment 3

[0028] Further change on the basis of Embodiment 1, the distance between the lower end of the partition 5 and the belt conveyor 10 becomes 60mm; the thickness of the partition 5 becomes 25mm; the thickness of the second insulation layer becomes 40mm. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com