Patents

Literature

66results about How to "Evenly seasoned" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

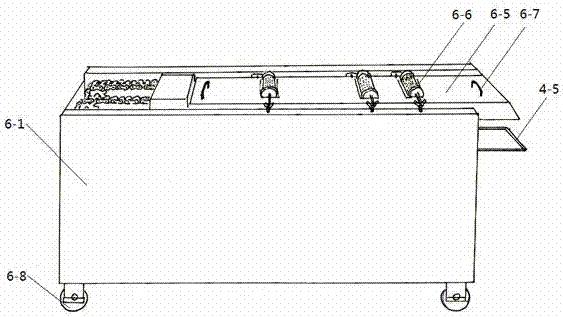

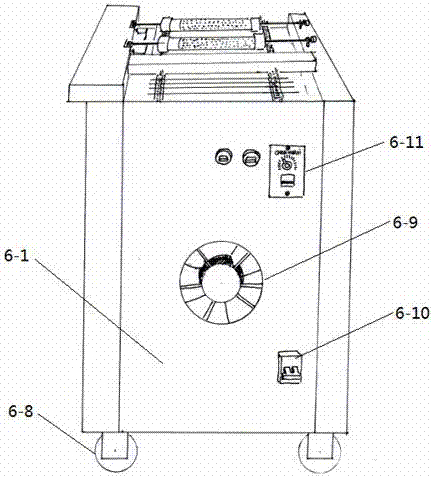

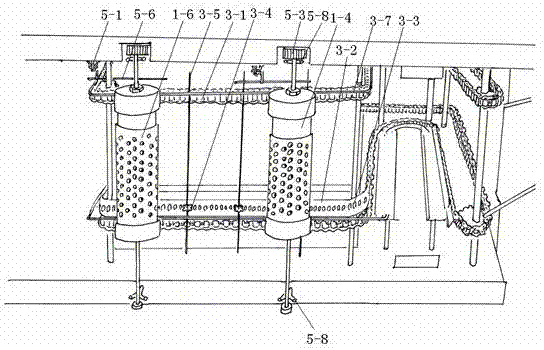

Environmentally friendly barbecue oven

ActiveCN107080470AIngenious structural designReduce baking timeClimate change adaptationRoasters/grillsProcess engineeringMechanical engineering

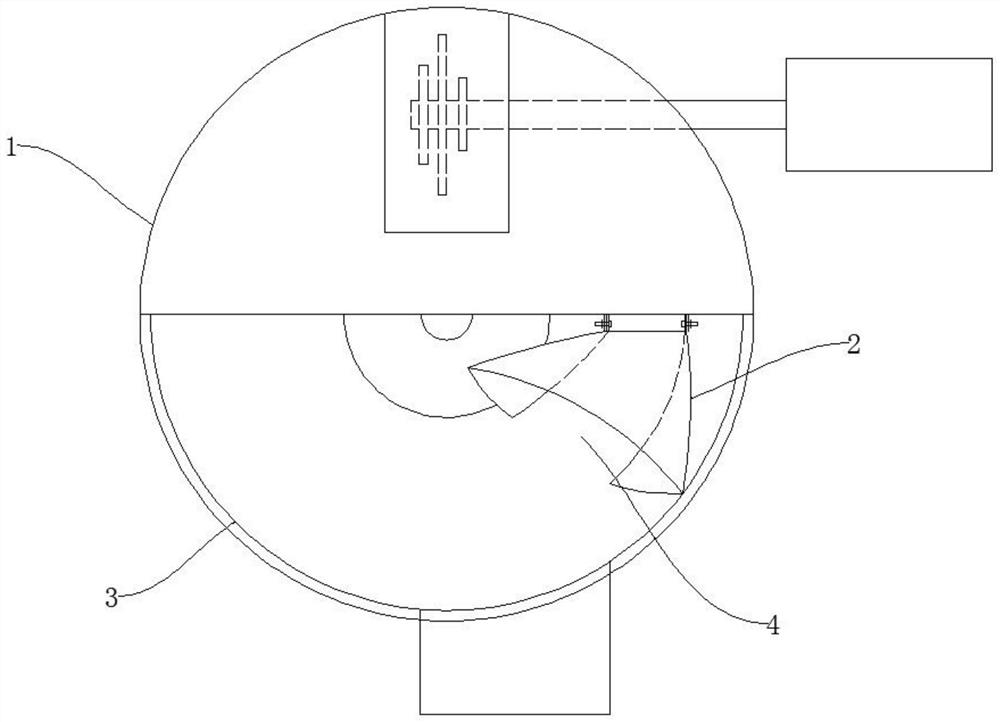

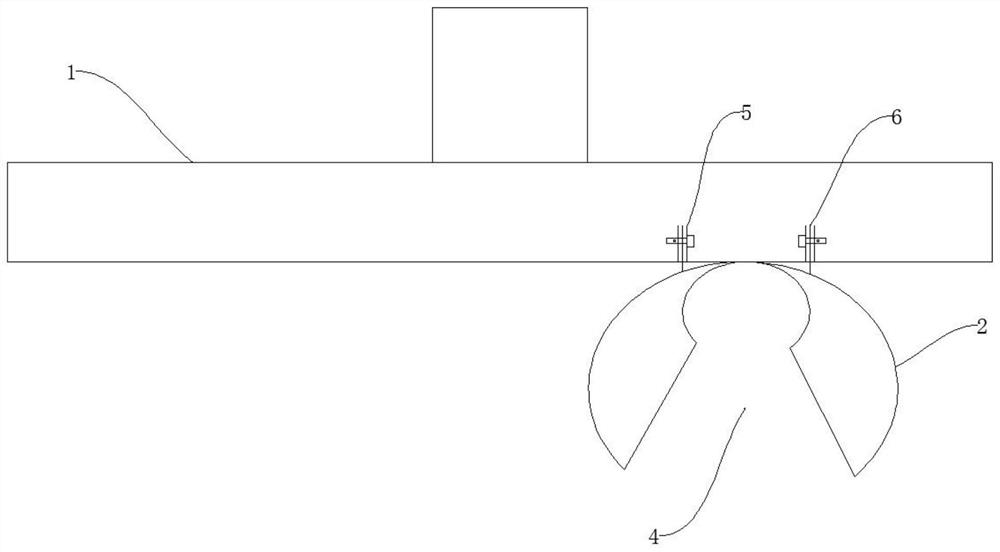

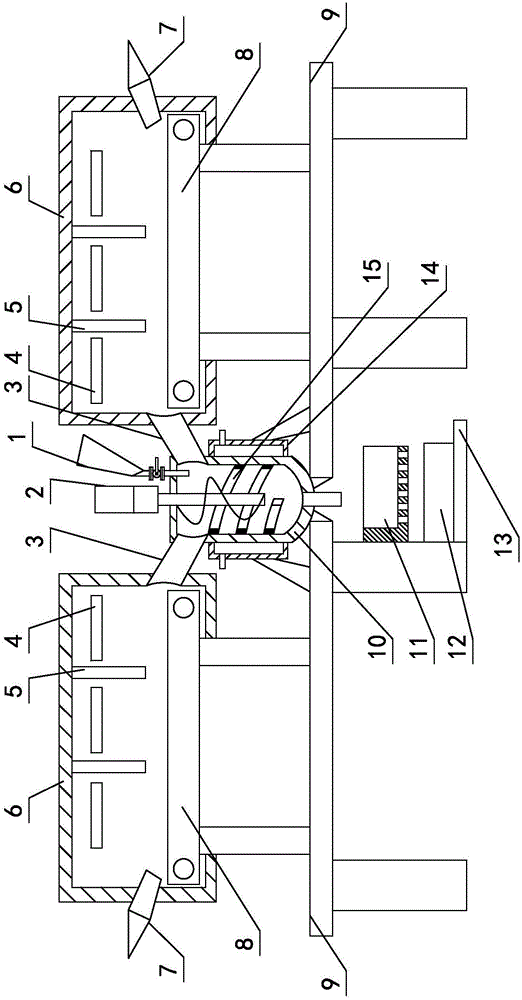

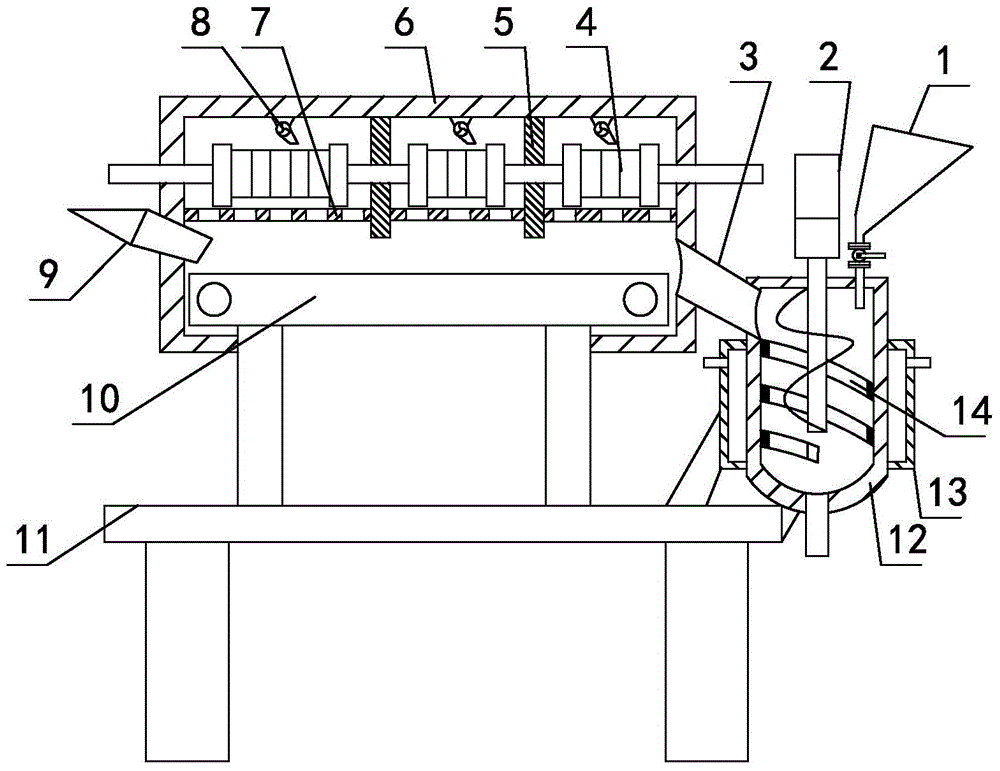

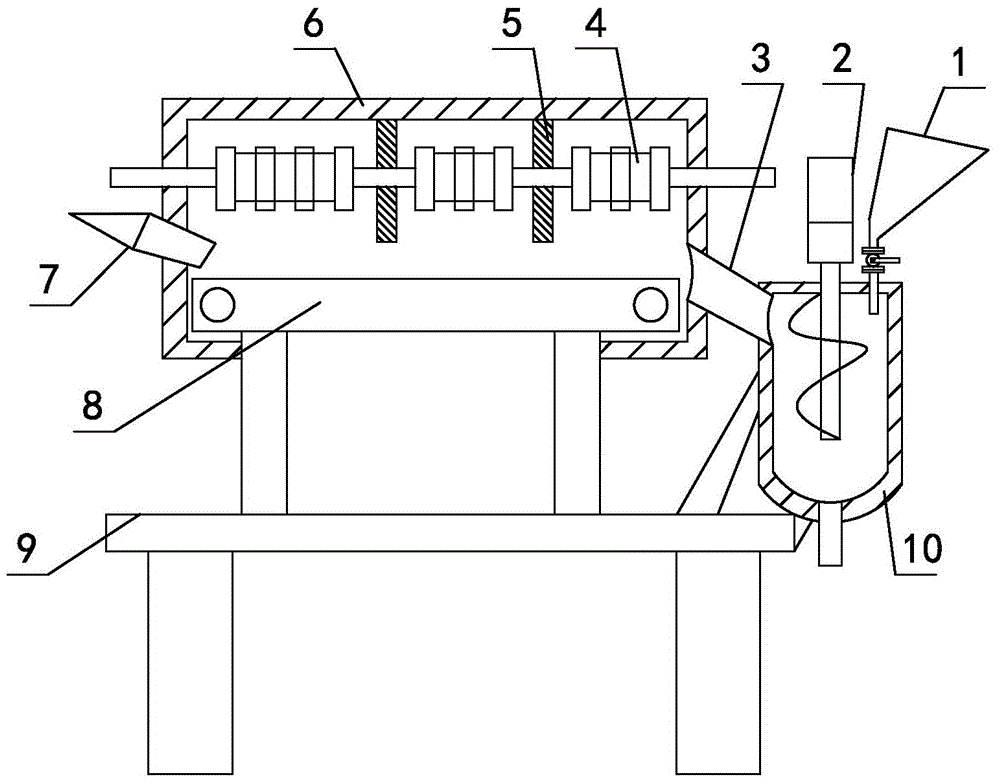

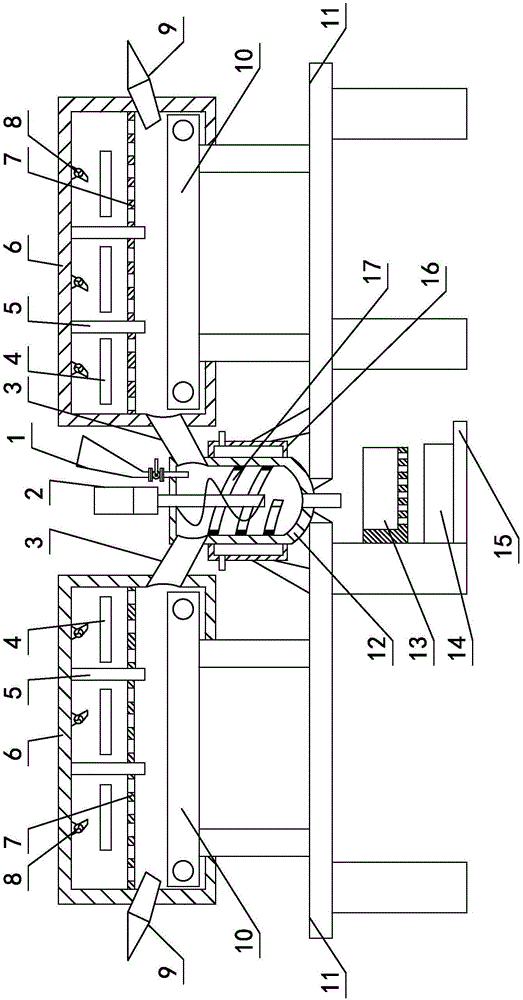

The invention relates to an environmentally friendly barbecue oven, and relates to the technical field of barbecue equipment structures. The barbecue oven comprises a barbecue oven body, and a plurality of carbon boxes at intervals are perpendicularly installed in the barbecue oven body; a skewer conveying device which can convey skewers and drive the skewers to rotate at 360 degree is arranged in the barbecue oven body, the skewer conveying device starts from one end of the barbecue oven body, winds the outer surfaces of the carbon boxes and extends to the other end of the barbecue oven body, and the skewer conveying device is driven by a driving mechanism in a connected mode; a plurality of seasoning adding devices which can rotate at 360 degree are arranged above the barbecue oven body, and an automatic skewer discharging device is arranged in the tail portion of the barbecue oven body. By means of the environmentally friendly barbecue oven, even roasting of skewers and even seasoning adding can be achieved, and the barbecue oven is energy-saving, environmentally friendly and healthy.

Owner:烟台陈工环保设备有限公司

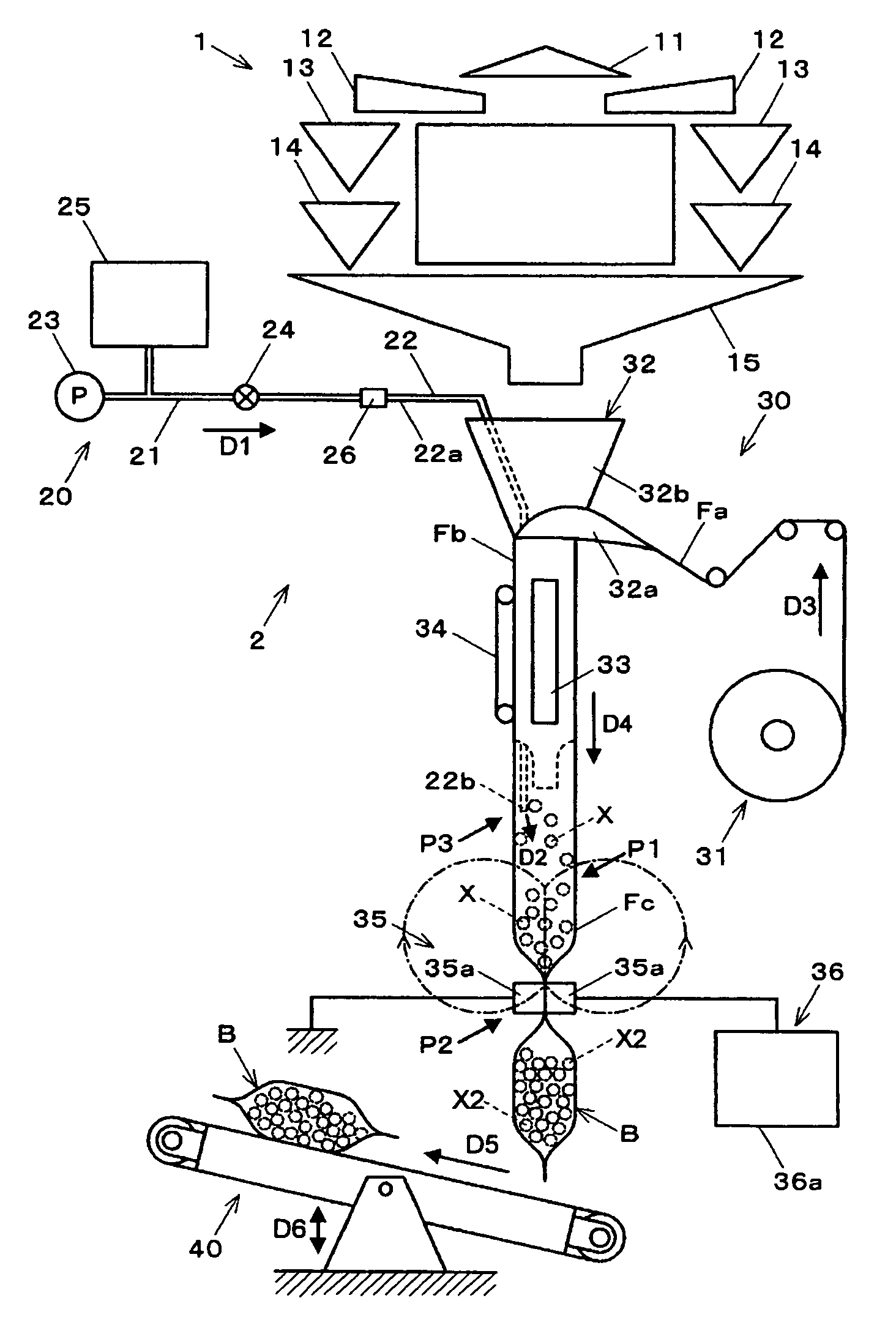

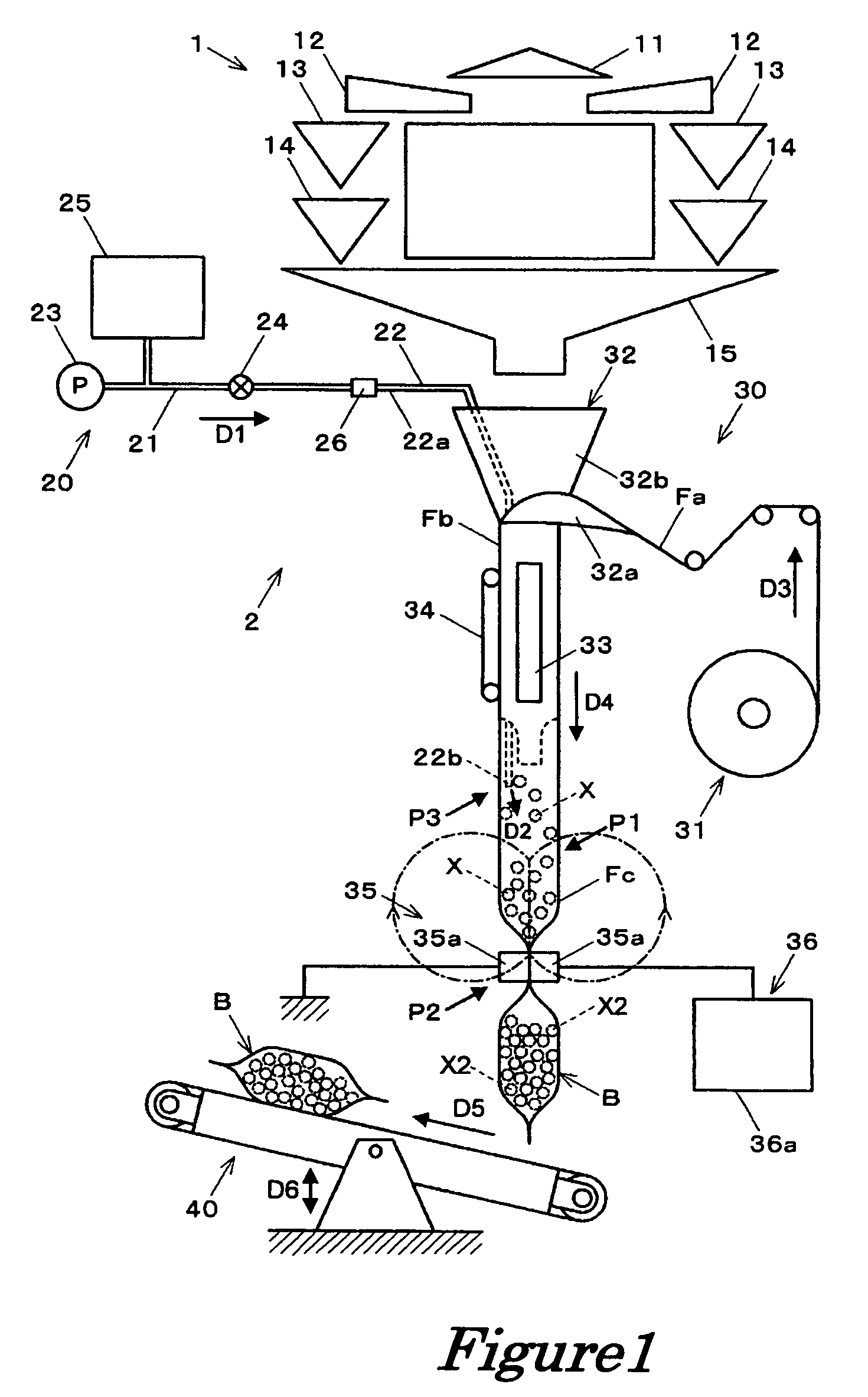

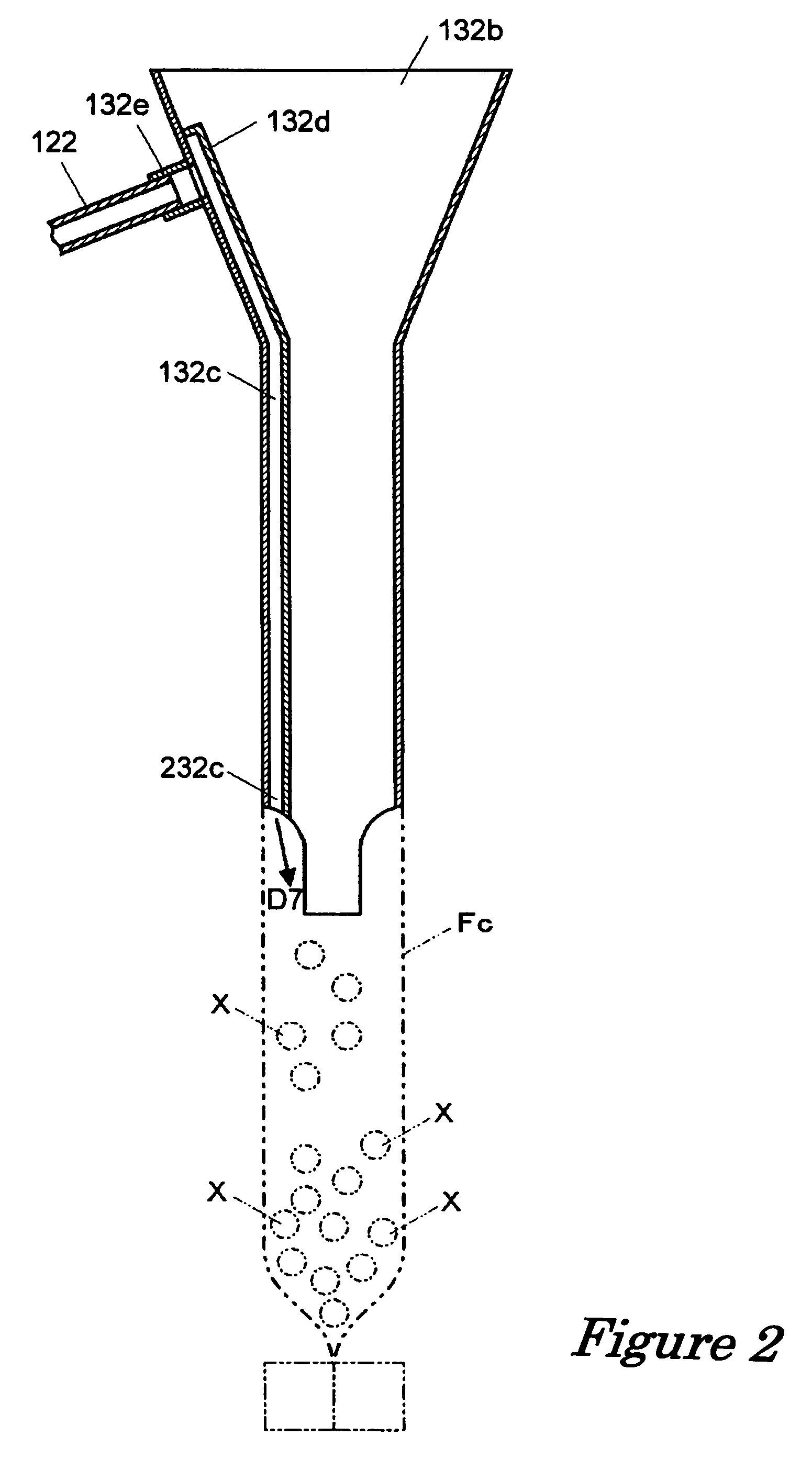

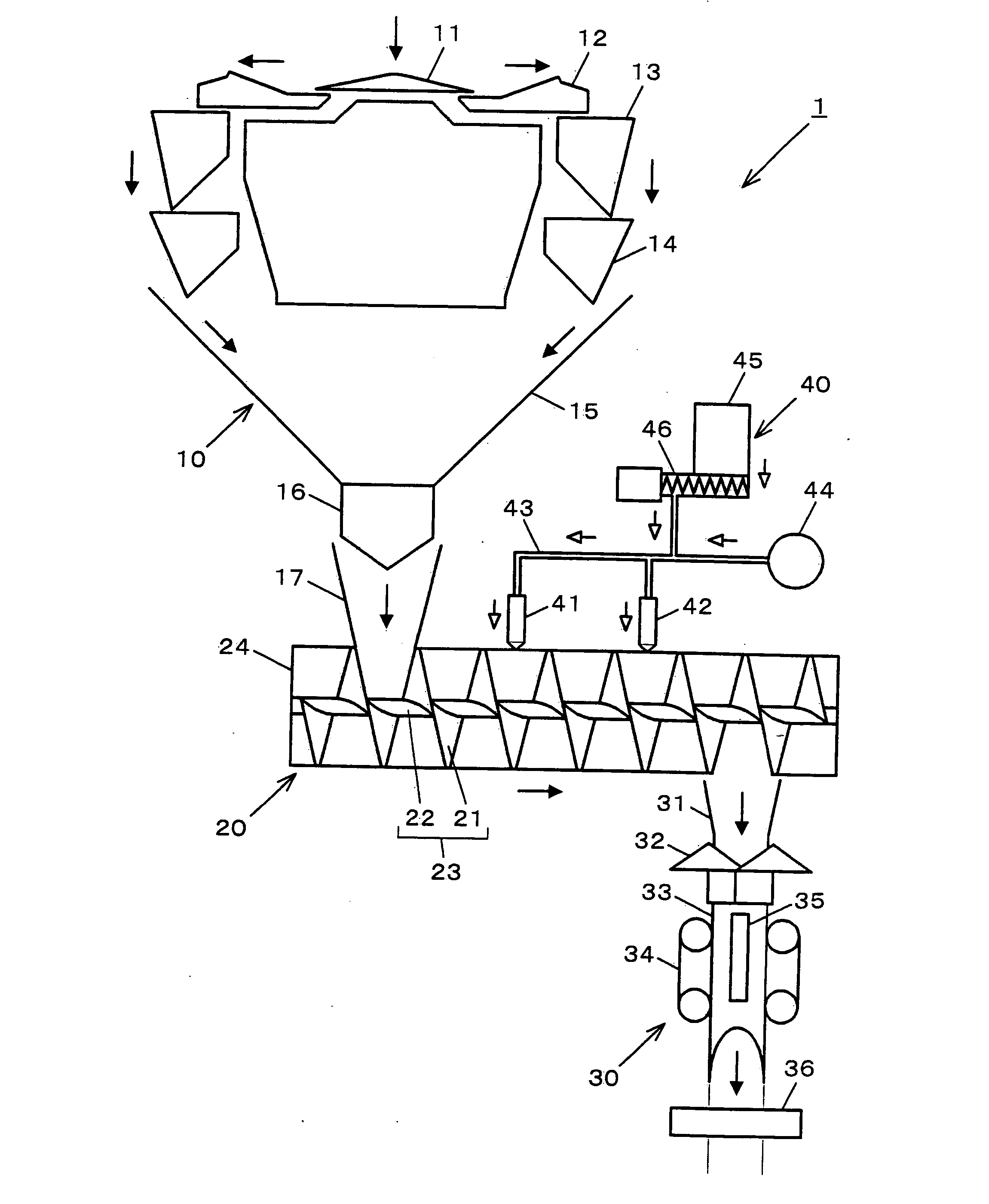

Seasoning treatment system

InactiveUS7228673B2Uniform processingEasy to cleanReady-for-oven doughsConfectioneryElectrical polarityEngineering

The present invention provides a seasoning processing system capable of uniform seasoning and, moreover, having superior cleanability. A seasoning processing system (2) according to the present invention comprises a seasoning dispersion apparatus (20) and a vertical pillow-type bag manufacturing and packaging apparatus (30). The seasoning dispersion apparatus (20) disperses powdered seasoning to be adhered to supplied intermediate articles (X . . . X) from an end part (22b), which is a dispersing mouth, of a second conduit (22). The vertical pillow-type bag manufacturing and packaging apparatus (30) introduces and packages inside a bag shaped packaging material (Fc) seasoned articles (X2. . . X2) to which the powdered seasoning has been adhered. Furthermore, the end part (22b), which is the dispersing mouth,of the second conduit (22) is provided and arranged so that it is positioned inside the bag shaped packaging material (Fc). A first electrical charging mechanism is provided to charge the seasoning with a polarity and a second electrical charging mechanism is provided to a transverse sealing mechanism of the packaging material to charge the packaging material with the same polarity as the seasoning. In this manner the seasoning and the packaging material repel each other during the sealing operation.

Owner:ISHIDA CO LTD

Method for processing sea-tangle sauce product

The invention discloses a kelp paste product processing method, which comprises immersing cut kelp material into acetic acid, pulling and placing, so as to soften the kelp and eliminate the odor; rinsing by brine, eliminating acetic acid and pollutant residual on the surface; rinsing with clean water, placing into a laminated cooker after water absorption, charging sodium carbonate according to aweight ratio of 1:1, boiling under microboiling state and agitation, modifying the kelp meat into paste; mixing the seasoning product uniformly, stirring while charging, and boiling continuously to make seasoning in uniform and permeable into the kelp; meanwhile, dissolving the composite thickening agent uniformly, charging citric acid and grinding, stirring while charging, and evaporating continuously to make seasoning in uniform and permeable into the kelp; finally, vessel filling according to a predetermined amount, draining little bulb by vacuum-pumping, filling the vessel and vacuum sealing for sterilizing in high temperature. The method eliminates odor of the kelp paste product, increases flavor, and enhances water keeping property and consistency, makes fluidity better.

Owner:厦门新阳洲水产品工贸有限公司

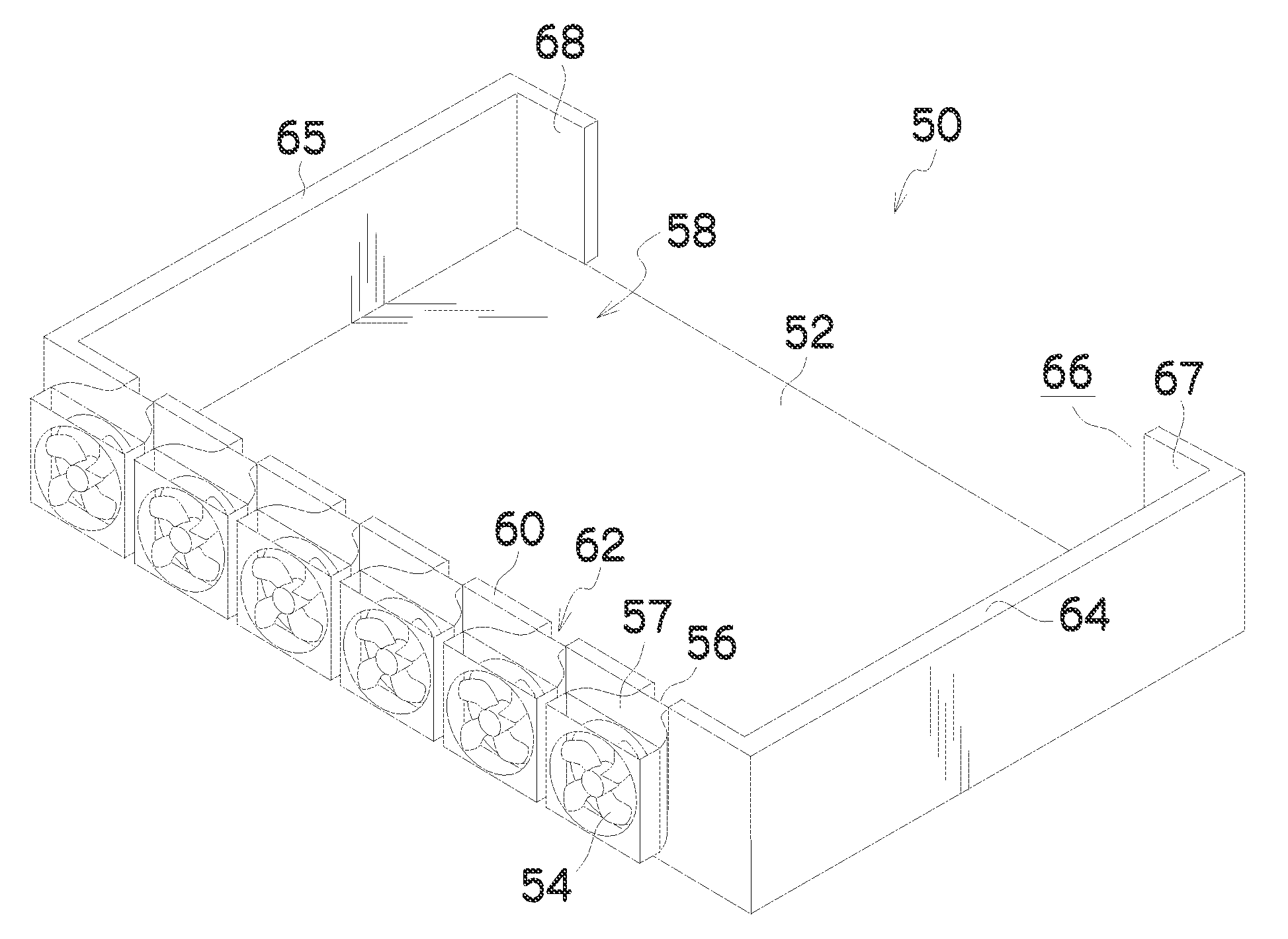

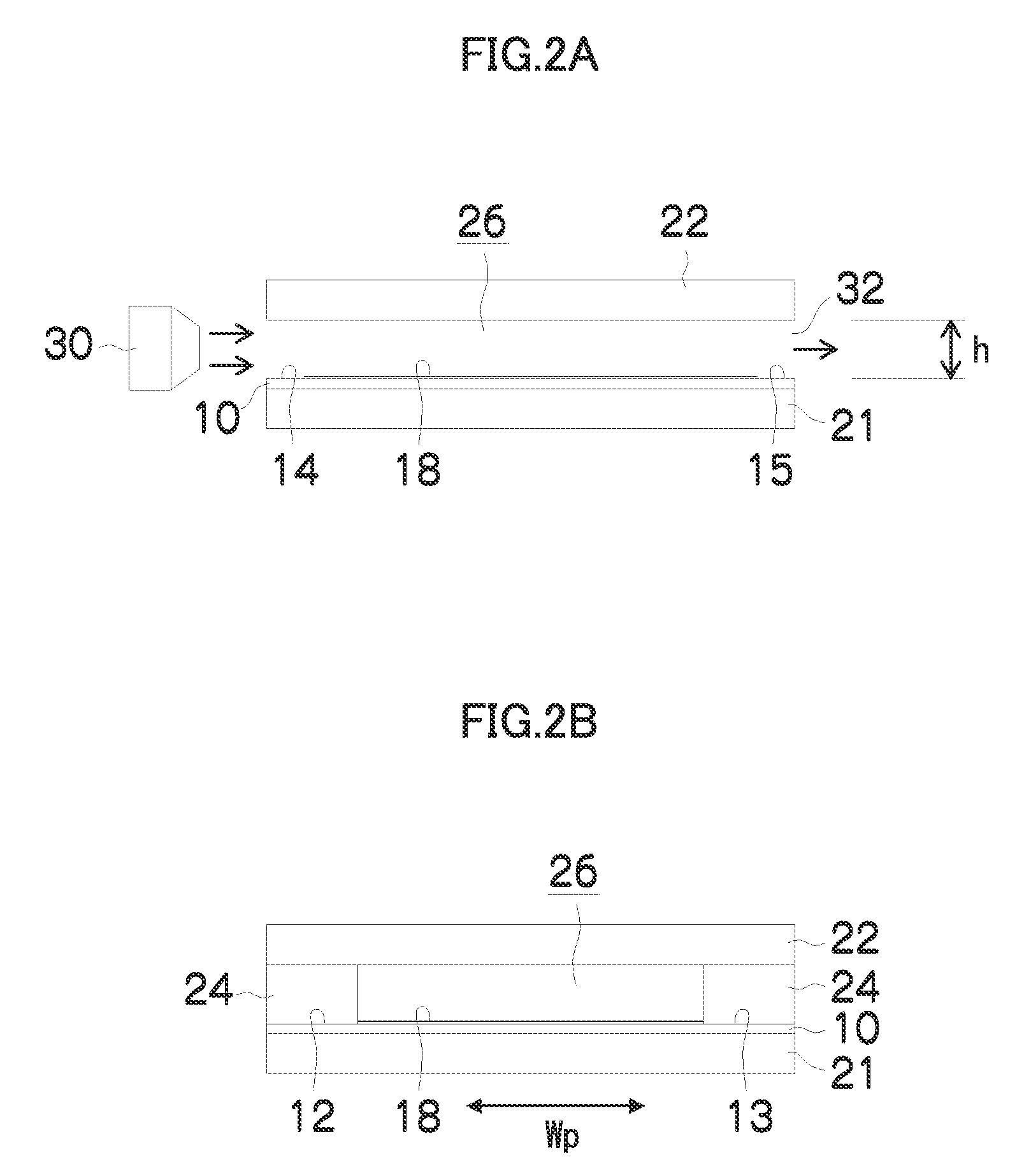

Printed matter seasoning apparatus and method, and inkjet recording apparatus

ActiveUS8297748B2Short processEvenly seasonedTypewritersPile receiversEngineeringElectrical and Electronics engineering

The printed matter seasoning apparatus includes: a table on which a plurality of sheets of printed paper are placed in a stack, ink having been deposited on at least one surface of each sheet of the printed paper; and an air blowing device which blows air toward at least one of end sides of the stack on the table to supply the air simultaneously between the respective sheets in the stack. The air blowing device blows the air at an air flow volume of at least 0.02 m3 / (min·m) per sheet of the printed paper and per unit length of the printed paper in a width direction thereof perpendicular to a direction from the air blowing device to the stack on the table.

Owner:FUJIFILM CORP

Production method of spicy deep-fried peanut kernels

InactiveCN103653065AEvenly seasonedInhibition of growth and reproductionFood preparationMicroorganismDeep frying

The invention discloses a production method of spicy deep-fried peanut kernels, belonging to the technical field of food finishing. The process flow comprises the following steps: selecting peanut kernels; decocting seasoning liquor; soaking peanuts; draining off; airing; deep-frying; draining oil; cooling; and vacuum packaging. The production method specifically comprises the following steps: (1) selecting peanut kernels; (2) decocting seasoning liquor; (3) soaking peanuts; (4) draining off; (5) airing; (6) deep-frying; (7) draining oil; (8) cooling; and (9) vacuum packaging. The spicy deep-fried peanut kernel product produced by the method is not only uniform in seasoner and different in taste due to different people, but also can inhibit growth and reproduction of microorganisms because of being soaked in the seasoning liquor, so that the expiration date of the product is prolonged.

Owner:QINGDAO BAOQUAN PEANUTS PRODS

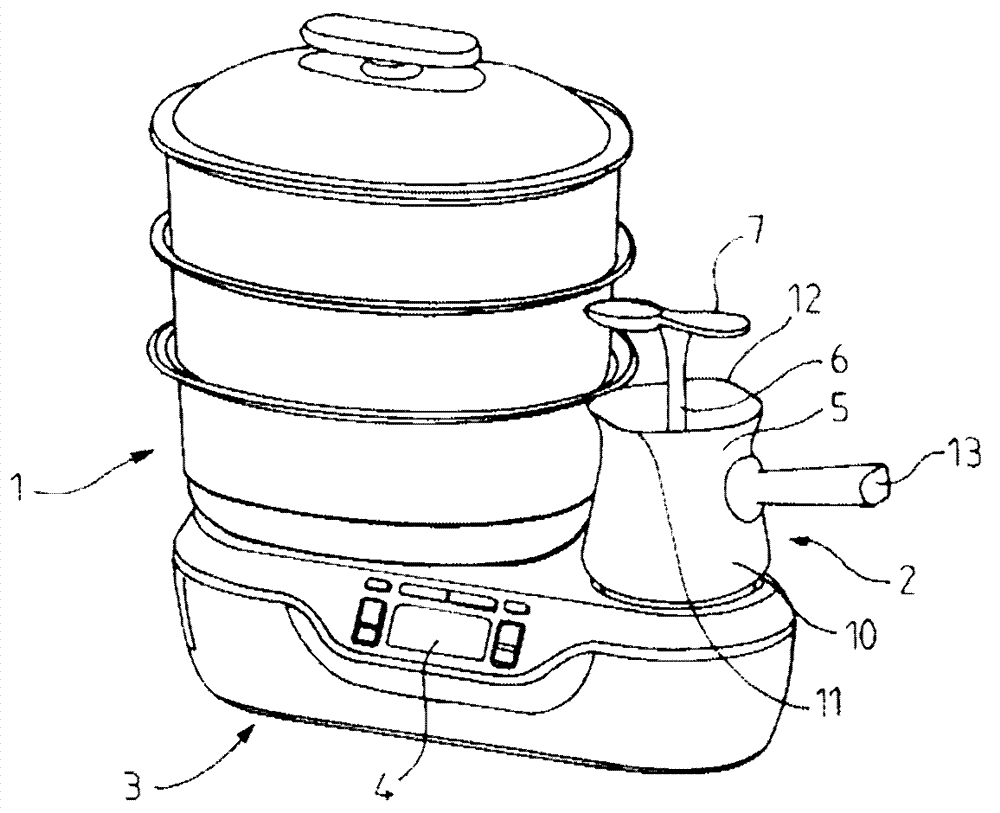

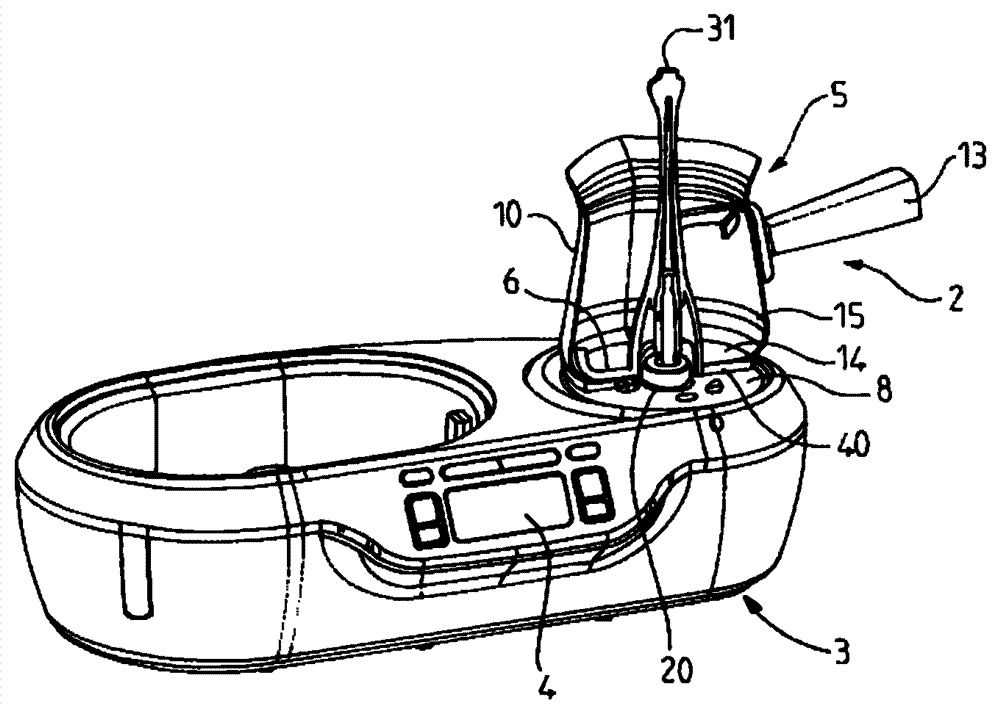

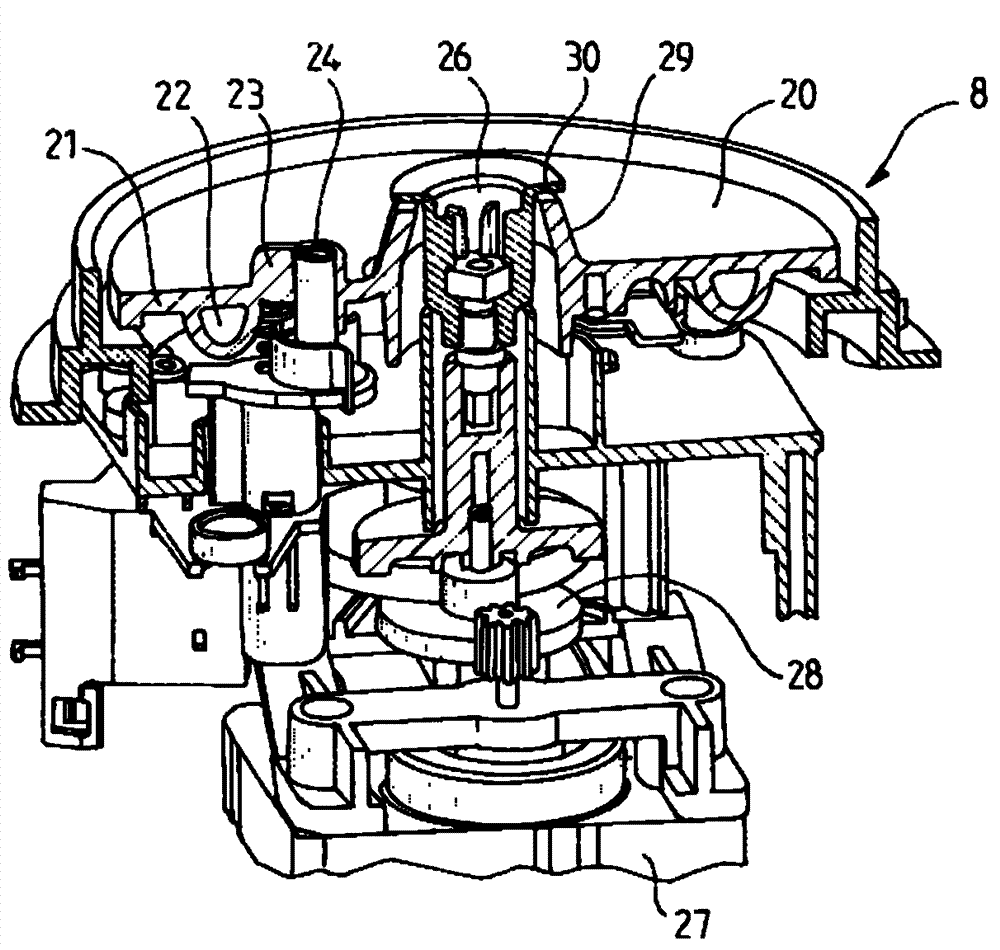

Household appliance for preparing smooth sauces

ActiveCN102764087AGood dispersionEvenly seasonedVessels with intergral heatingMechanical engineeringFood preparation

The invention relates to an electrical household appliance for hot food preparation, comprising a tank (5) having a bottom (14) and a side wall (15), and also a blade (6) that is driven in rotation in the tank (5), the blade (6) having a lower arm (62) that extends above the bottom (14) of the tank (5), the lower arm (62) comprising a turned-up end (64) that forms a peripheral passage (70) with the side wall (15) of the tank (5). - According to the invention, the peripheral passage (70) has an upper narrowing (71).

Owner:SEB SA

Production method of salty fried peanuts

The invention discloses a production method of salty fried peanuts and belongs to the technical field of peanut food processing. The preparation method comprises the following steps: selecting peanuts, preparing a saline solution, soaking the peanuts, draining, drying, frying the peanuts with oil, draining oil, cooling and vacuumizing. The fried peanuts produced through the above steps not only has even and good taste but also can inhibit growth and propagation of microbes to extend the shelf life of the product, due to immersion in saline solution.

Owner:QINGDAO BAOQUAN PEANUTS PRODS

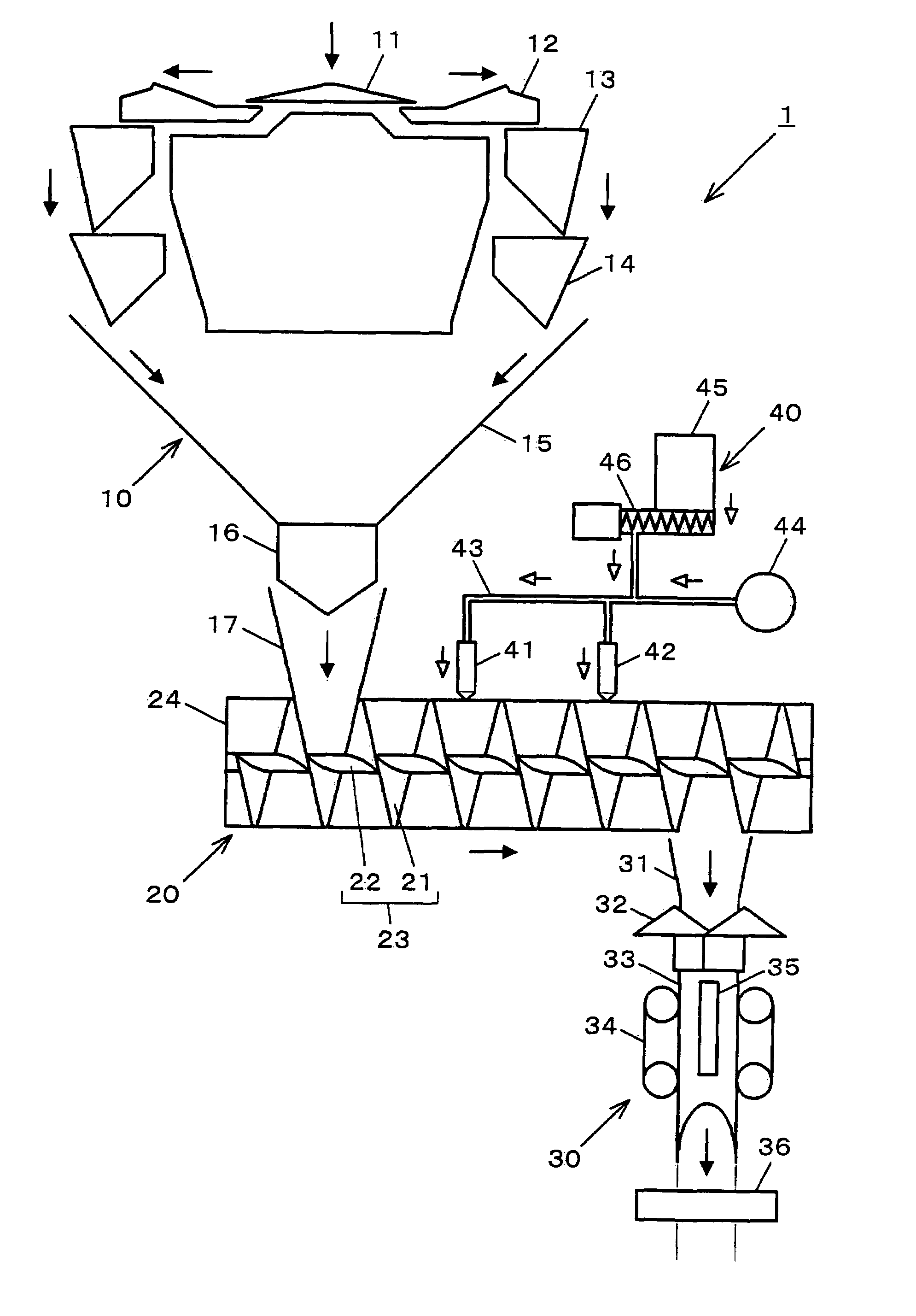

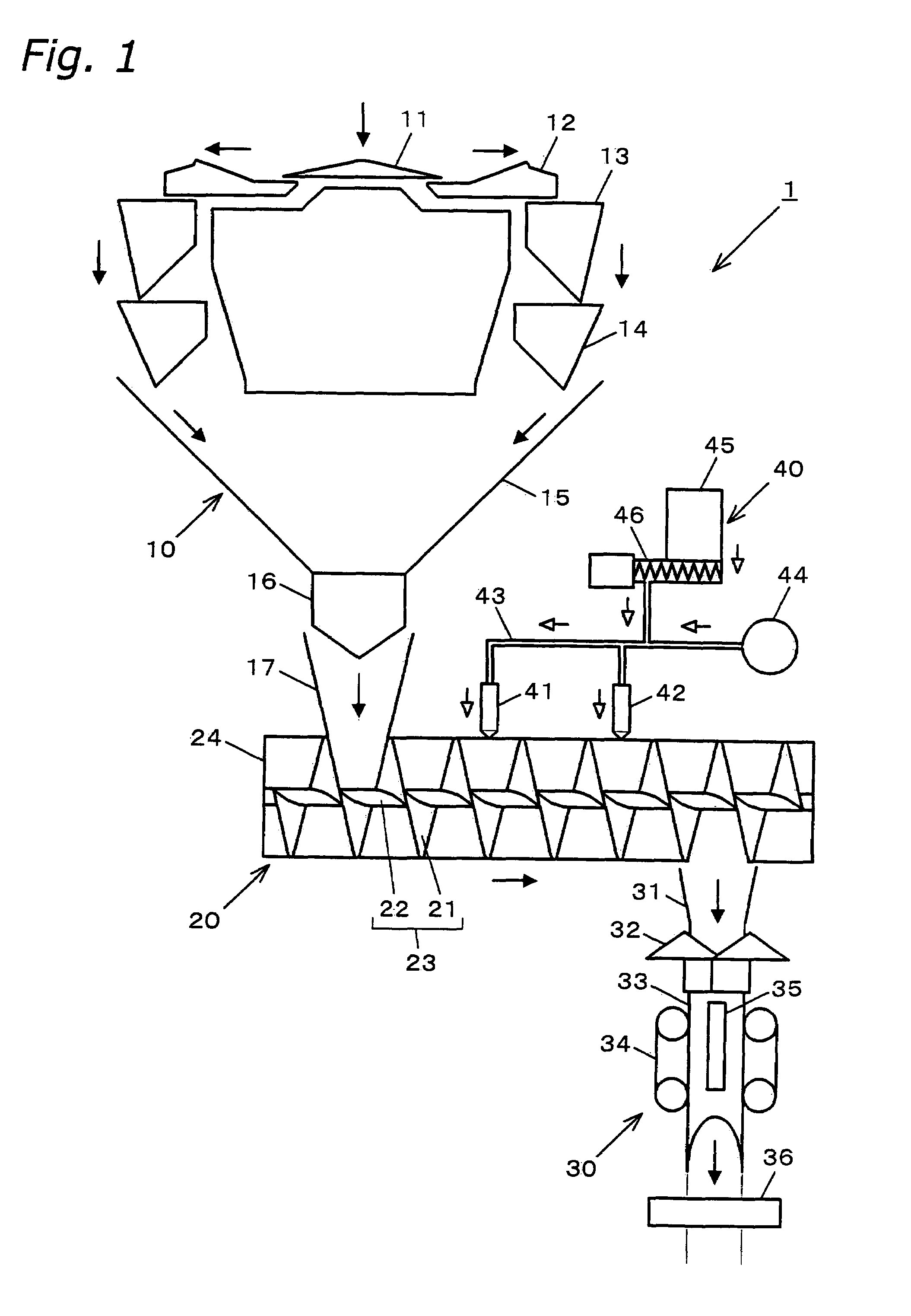

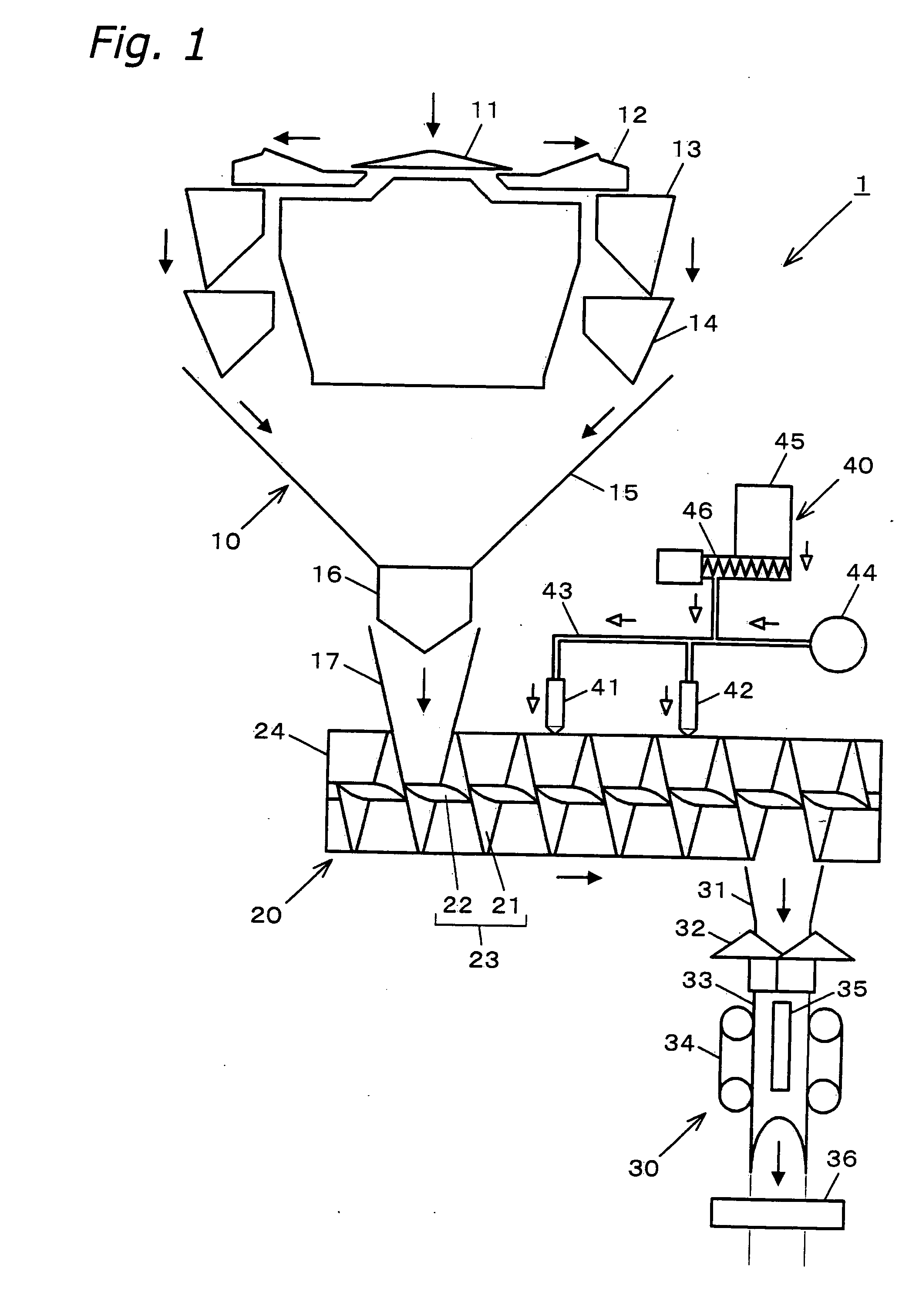

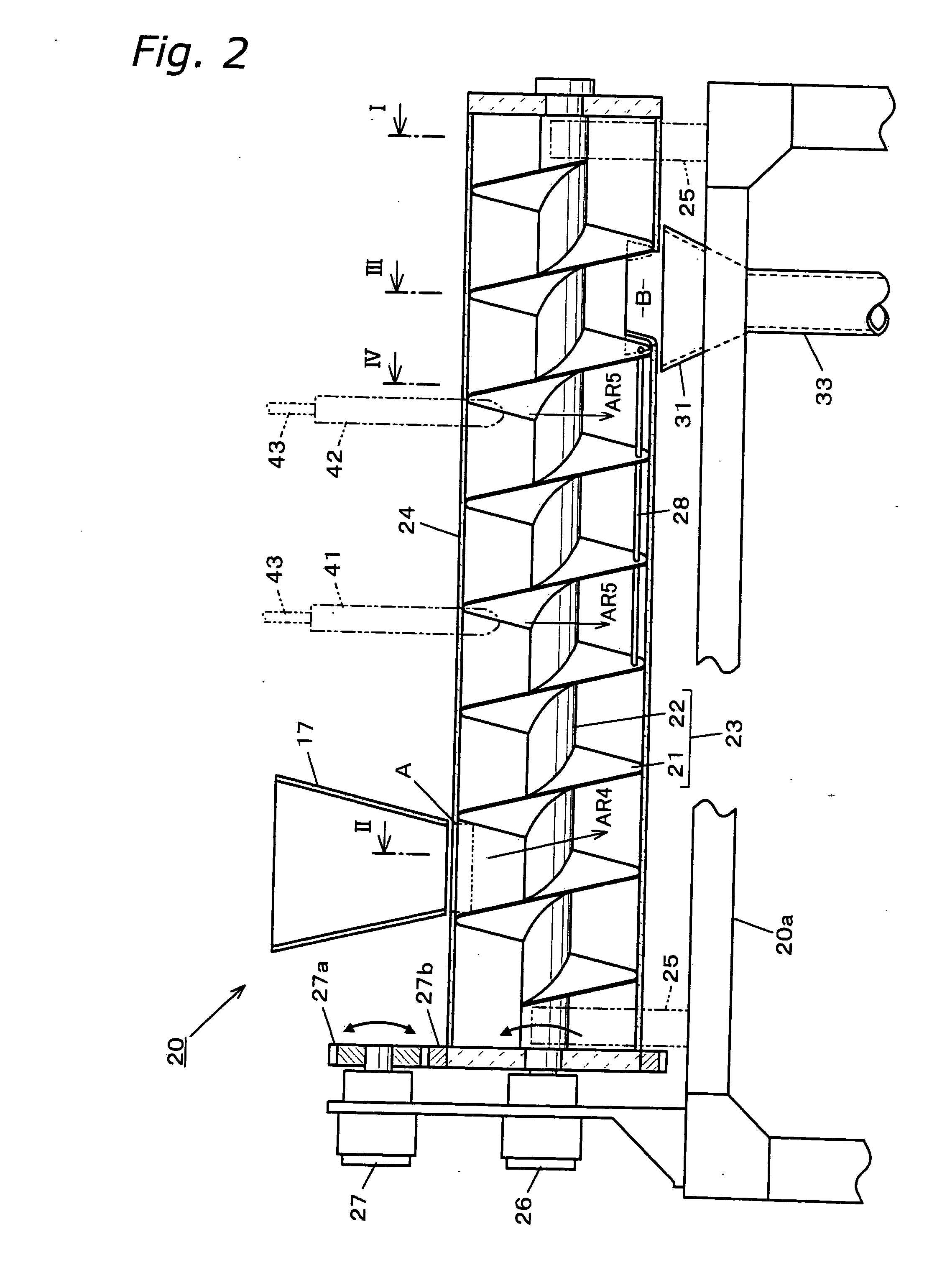

Seasoning apparatus, and product manufacturing system provided therewith

The present invention provides a seasoning apparatus capable of evenly seasoning each individual article, without seasoning any too heavily or too lightly. Therein, a screw having a helical blade is installed in a tube. The helical blade provides partitions that are provided upright between an article supply port and a discharge port. An article group, before seasoning, is accommodated in a section partitioned by the partitions, the motor rotates the screw, and the article group is transported from the supply port to the discharge port. Therein, each article group is transported to the discharge port separated from other article groups, and each individual article in the article group is seasoned evenly with the same seasoning processing time and the same seasoning supply ratio. In addition, the constitution of the seasoning apparatus is simplified because the screw simultaneously serves the two functions of separating and transporting the article groups.

Owner:ISHIDA CO LTD

High-temperature sterilized low-salt instant minced fish product

InactiveCN104432222AEasy to digest and absorbHigh nutritional valueFood preservationFood preparationChemistryFlavor

The invention relates to the field of food processing and storage, in particular to a high-temperature sterilized low-salt instant minced fish product and a preparation method thereof. The instant minced fish product is heated and formed through microwave to form a gel or porous structure and is subjected to high-temperature sterilization to keep the high-elasticity gel or porous texture; the instant minced fish product is prepared from the following steps: chopping the minced fish; drying the minced fish blocks, wherein the drying mode is cold air drying or hot air drying, and the minced fish blocks are dried until the moisture content is 50-60 percent; performing microwave heating until the minced fish is gel-shaped or porous; placing the product in flavor liquid to soak; packaging the product and then performing high-temperature sterilization to obtain a finished product. The product is heated and formed by the microwave to form the gel or porous structure, is soaked by the flavor liquid and is subjected to high-temperature sterilization to obtain the high-elasticity normal temperature circulation instant minced fish new product, so the minced fish product requirements of consumers on conditioning, convenience and gel food feature can be met better, and the defects of the prior art are made up.

Owner:WEIFANG MEDICAL UNIVERSITY

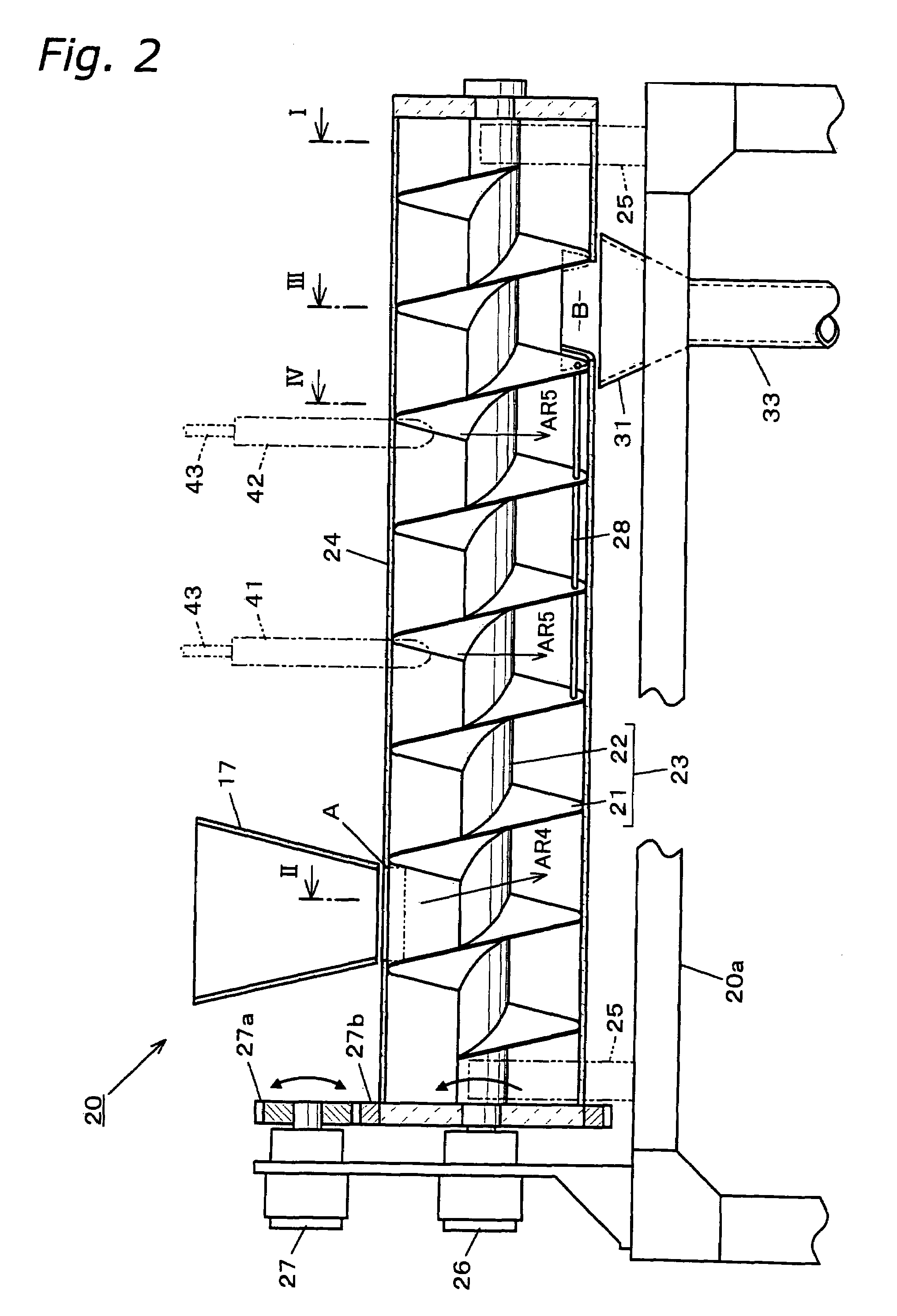

Seasoning device and commodity production system with the device

InactiveUS20040244681A1Evenly seasonedStir wellLiquid surface applicatorsConfectioneryHelical bladeI e ratio

The present invention provides a seasoning apparatus (20) capable of evenly seasoning each individual article, without seasoning any too heavily or too lightly. Therein, a screw (23) having a helical blade (21) is installed in a tube (24). The helical blade (21) provides partitions that are provided upright between an article supply port (A) and a discharge port (B). An article group, before seasoning, is accommodated in a section partitioned by the partitions, the motor (26) rotates the screw (23) in that state, and the article group in the section is thereby transported from the supply port (A) to the discharge port (B). Therein, each article group is transported to the discharge port (B) separated from other article groups, and each and every individual article in the article group is seasoned evenly with the same seasoning processing time and the same seasoning supply ratio. In addition, the constitution of the seasoning apparatus (20) is simplified because the screw (23) simultaneously serves the two functions of separating and transporting the article groups.

Owner:ISHIDA CO LTD

Processing technology of spiced peanut kernels

The invention discloses a processing technology of spiced peanut kernels. The processing technology comprises the following steps: preparing raw materials, namely selecting high-quality peanut kernels which are full in kernels, do not have skin damages and cannot cause mildew and rancidity, and storing in a dry place for later use; blanching, namely completely cleaning the peanut kernels by using clean water, then pouring into boiling water, and blanching for 2-3 minutes; pickling, namely putting a seasoning which is prepared from anise, pricklyash peel, bark of Japanese cinnamon, ginger, table salt, dark soybean sauce, monosodium glutamate and white sugar into a pot, adding a proper amount of water, boiling to prepare flavoring liquid, adding the peanut kernels into the flavoring liquid, and pickling for 2-4 hours; bagging and sealing, namely weighing and sub-packaging the pickled peanut kernels according to specifications, and sealing by using a vacuum packaging machine after bagging, wherein the sealing conditions are that the vacuum degree is 0.085-0.095MPa and the heat-sealing voltage is 28-32KV; and sterilizing, namely putting the bagged and sealed peanut kernels into a high-pressure sterilization cooker, and sterilizing for 25-35 minutes at 120-122 DEG C. The spiced peanut kernels disclosed by the invention are simple in process, good in taste and uniform in flavoring, also have storage tolerance, are convenient to carry, and are ready-to-eat.

Owner:QINGDAO XIUXIAN FOODS

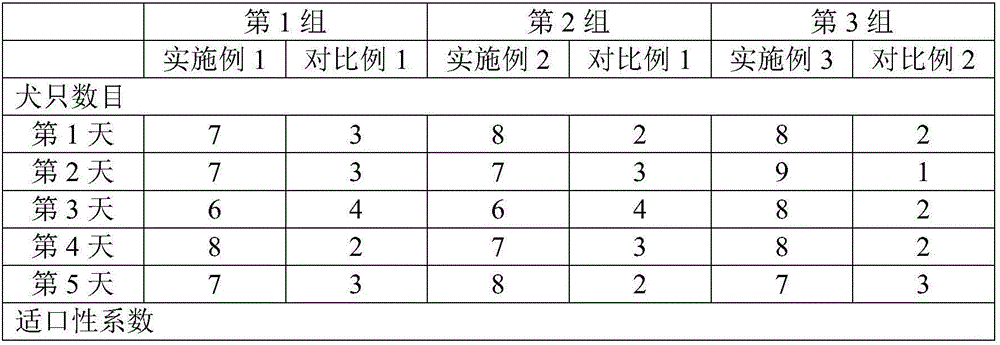

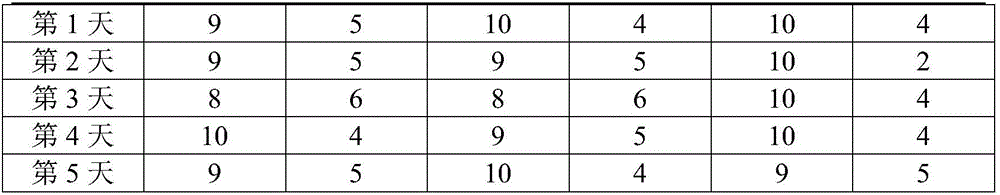

Sausage for pets, and making method thereof

InactiveCN106578569AUnique flavorImprove palatabilityAnimal feeding stuffBiotechnologyFood flavorings

The invention discloses a sausage for pets. The sausage comprises a casing and a sausage material canned in the casing, and the sausage material comprises, by weight, 50-100 parts of meat, 2-12 parts of modified starch, 0.1-1 part of white sugar, 1-8 parts of a food flavoring, and 0.5-4 parts of mashed garlic. The sausage for pets has the advantages of unique flavor, good palatability, improvement of the eating interest of pets, balanced nutrition, facilitation of the health of bodies of the pets, and convenience in carrying and storage. The invention also discloses a making method of the sausage for pets. The method has the advantages of few steps, simple flow, and safety in operation.

Owner:SHANDONG HAICHUANG IND & TRADE CO LTD

Dried meat floss production method

The invention belongs to the technical field of meat product processing, and specifically relates to a dried meat floss production method, which comprises the following steps: carrying out oil removing, fascia removing, finishing and classification on fresh qualified pork hind leg lean; observing the meat fiber direction, and carrying out block cutting; washing to remove blood, and draining; carrying out boiling three times according to the lean classification and the individual heating degree characteristics, slowly boiling for 1 h with mild fire after boiling with strong fire, removing floating oil, foams and impurities on the surface of the soup every 1 h, and flipping the lean in the soup so as to achieve uniform heating; mincing and beating loosely the obtained meat blocks into the filamentous meat; and the like. Compared with the traditional dried meat floss production process, the production process of the present invention has the following characteristic that: the produced dried meat floss has characteristics of high moisture content, uniform seasoning and storage resistance. Particularly the boiling stage of the production process of the present invention is divided into the three boiling, such that the dried meat floss production method of the present invention is reasonable.

Owner:陈祥萍

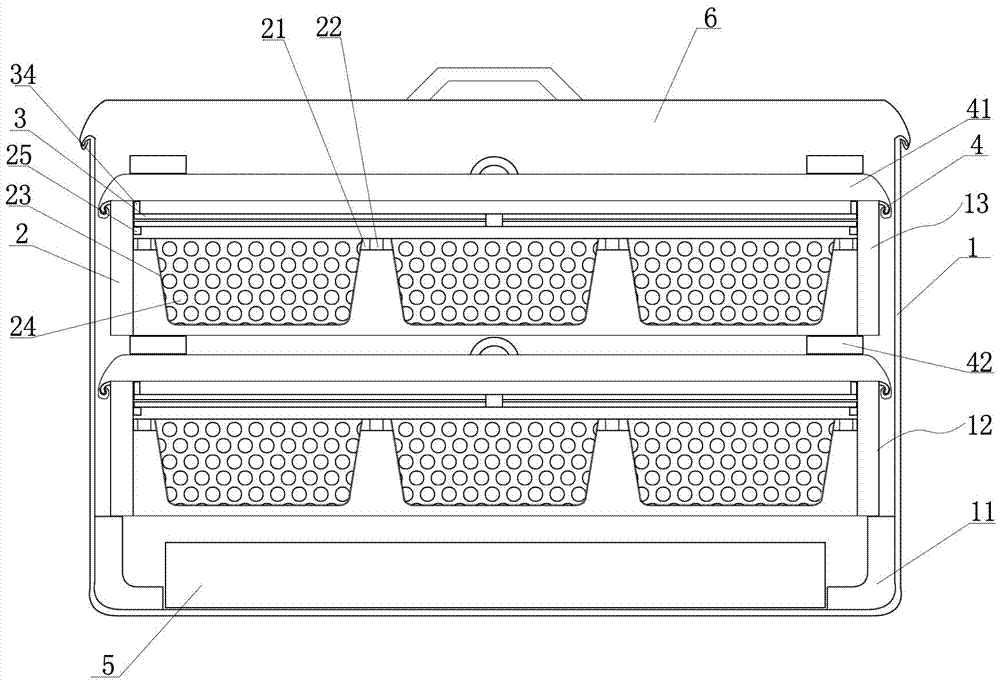

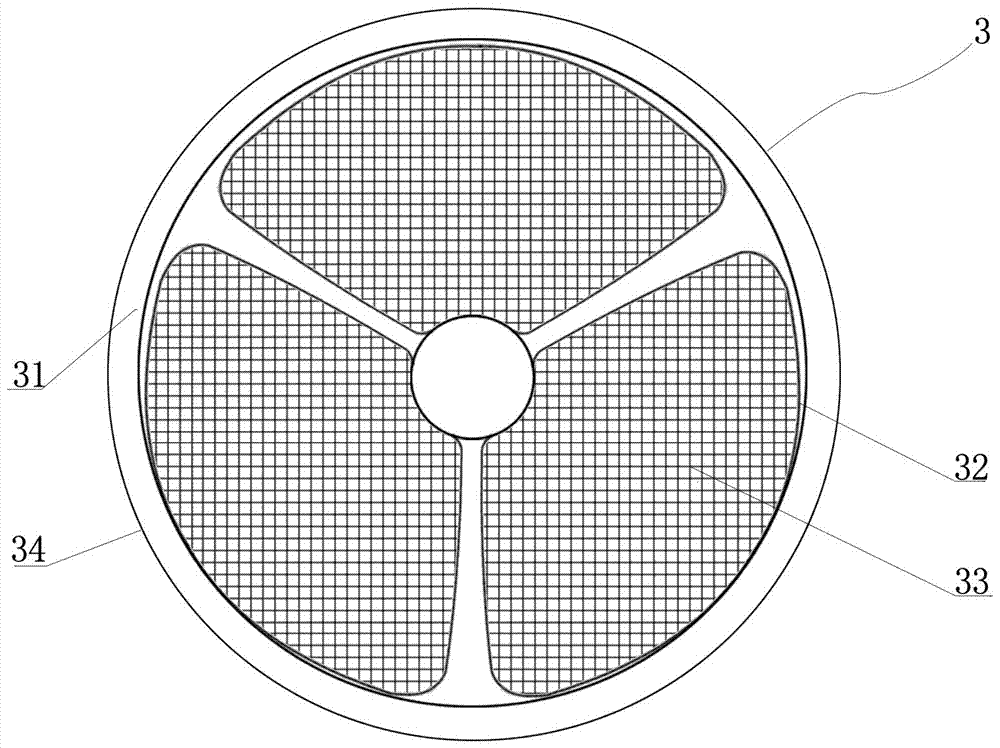

Steaming device for crabs

InactiveCN107157308AEven heat cookingGreat tasteSteam cooking vesselsCooking insertsEngineeringMechanical engineering

The invention discloses a steamer for crabs, which comprises a hollow cylindrical casing, and a plurality of "L"-shaped brackets are arranged on the outer end of the bottom of the casing, and a lower storage plate is placed on the bracket, and the lower container The upper part of the storage tray is placed with an upper storage tray, the lower storage tray and the upper storage tray both include a circular support ring, a support plate is horizontally connected to the support ring, and the support plate is arranged at a circular equidistant distance from the bottom. A circular accommodating cavity for placing crabs. The accommodating cavity is in the shape of a large and small cone. The sides of the accommodating cavity are provided with a number of through holes. The supporting ring is provided with a connecting ring on the upper part of the supporting plate. A seasoning tray is placed on the connecting ring, and the top of the support ring is provided with a flipped arc-shaped card edge outward. The top of the support ring is provided with a top cover, and the top cover is clamped on the card edge. A plurality of shelves are provided, and the upper accommodating tray rests on the shelf of the lower accommodating tray.

Owner:KUNSHAN FUZONE NETWORK TECH

Meatloaf with flavor of salted egg yolk and making method of meatloaf

The invention discloses meatloaf with the flavor of salted egg yolk and a making method of the meatloaf. The meatloaf is prepared from, by weight, 900-1,000 parts of fish, 400-500 parts of streaky meat, 300-400 parts of water, 500-600 parts of starch, 6-10 parts of fresh ginger, 1-2 parts of sesame oil, 2-3 parts of chicken essence, 80-100 parts of egg white, 80-100 parts of salted egg yolk, 8-10parts of soy sauce, 20-25 parts of edible salt, 6-8 parts of white sugar, 4-5 parts of table vinegar, 6-8 parts of rice wine and 50-60 parts of egg yolk. The meatloaf with the flavor of salted egg yolk is gray white in appearance and has yellow laying pulp on the surface and is attractive in color and luster, the profile of the meatloaf is of a loose and porous structure, meat particles are addedinto the meatloaf, and the meatloaf is elastic and easy to eat, has both freshness and deliciousness of fish and meat and the unique salty flavor of the salted egg yolk, is delicious but not greasy, and palatable in freshness and saltness.

Owner:HUBEI SHENDAN HEALTHY FOOD

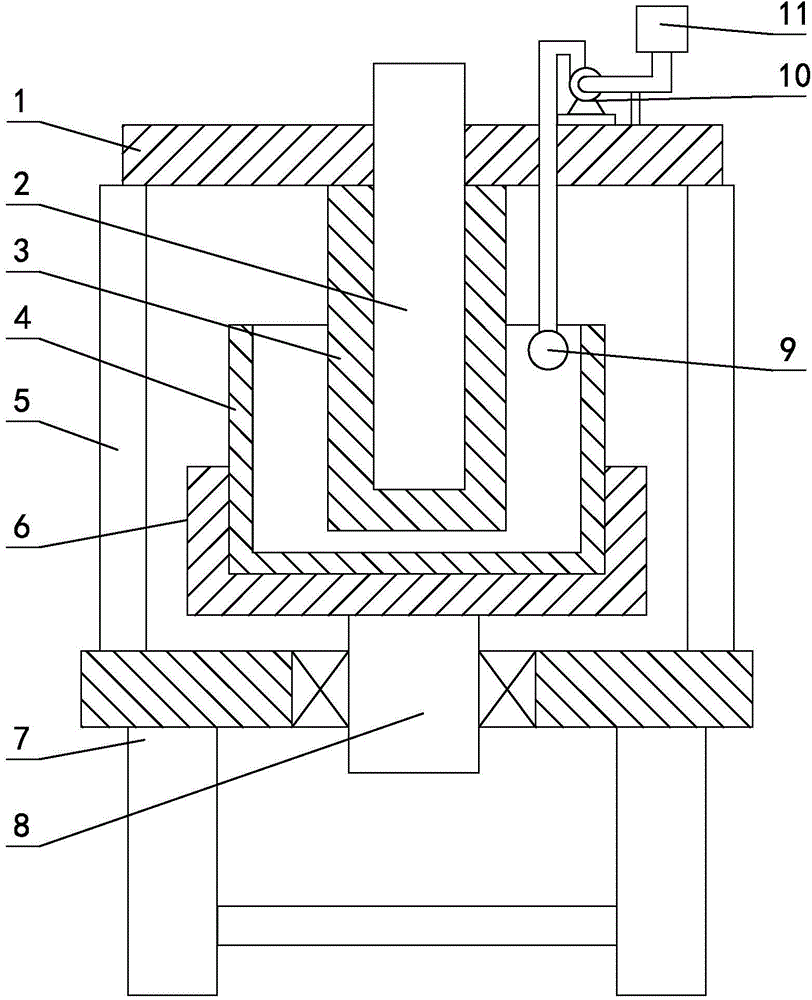

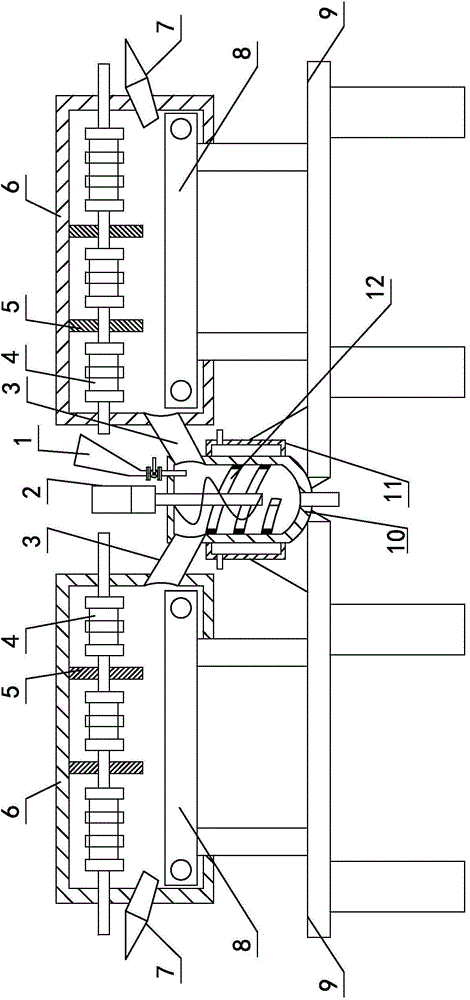

Quick-seasoning household seed and nut frying machine

The invention relates to a quick-seasoning household seed and nut frying machine and belongs to the technical field of seed and nut frying machines. The quick-seasoning household seed and nut frying machine comprises a workbench; a rotor shaft is vertically installed on the workbench; a rotor cylinder is installed at the top of the rotor shaft; inner tanks are arranged in the rotor cylinder, wherein the inner tanks are in mutual rotation fit and can be freely taken out from the rotor cylinder; heating core columns are arranged in the inner tanks, wherein the heating core columns are mutually independent; electric heating rods are installed in the heating core columns; the upper ends of the heating core columns are exposed outside the inner tanks; mounting panels are fixed at the upper ends of the heating core columns; supporting parts are arranged on the workbench for supporting the mounting panels; the mounting panels can be freely taken off the supporting parts; material-charging nozzles are arranged in the inner tanks between the heating core columns and the inner tanks; the material-charging nozzles are connected to a material-charging pump by pipelines; and the material-charging pump is connected with a material-charging groove by pipelines. According to the invention, the quick-seasoning household seed and nut frying machine is simple in structure, small in floor area, low in production cost, very suitable for household seed and nut frying at home, convenient to operate and uniform in baking and frying effects.

Owner:CHONGQING MAODE AGRI DEV CO LTD

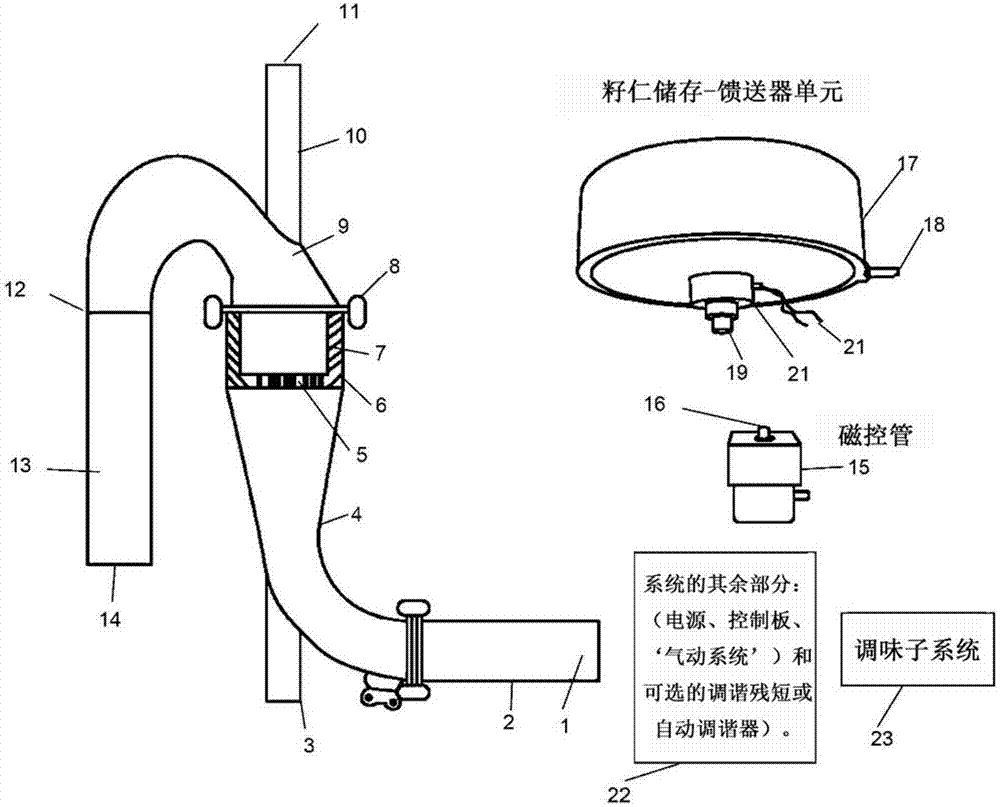

Method and system for processing and/or flavouring foodstuffs

InactiveCN107531394AImprove experienceEvenly seasonedPowdered material dispensingClosuresEngineeringFood item

The present invention relates to the field of processing and / or flavouring foodstuffs. In one aspect of invention, there are methods and / or devices related to foodstuff suitable for popping, such as kernels, as well as flavouring foodstuffs. In another aspect of invention, there is provided a method of and / or device for providing flavouring into a sealed container, comprising providing a container, providing a pod having flavouring therein, attaching the pod to the container, and using the pod to deliver the flavouring into the container. In yet another aspect, there is provided a pod adaptedto provide flavouring to foodstuff and / or a method therefor, comprising a housing adapted to holding at least one flavouring, a piercing element, provided within the pod, an attachment mechanism for attaching the pod to a bag or container, and a frangible surface operative in use with the piercing element.

Owner:LUMINUTTY PTY LTD

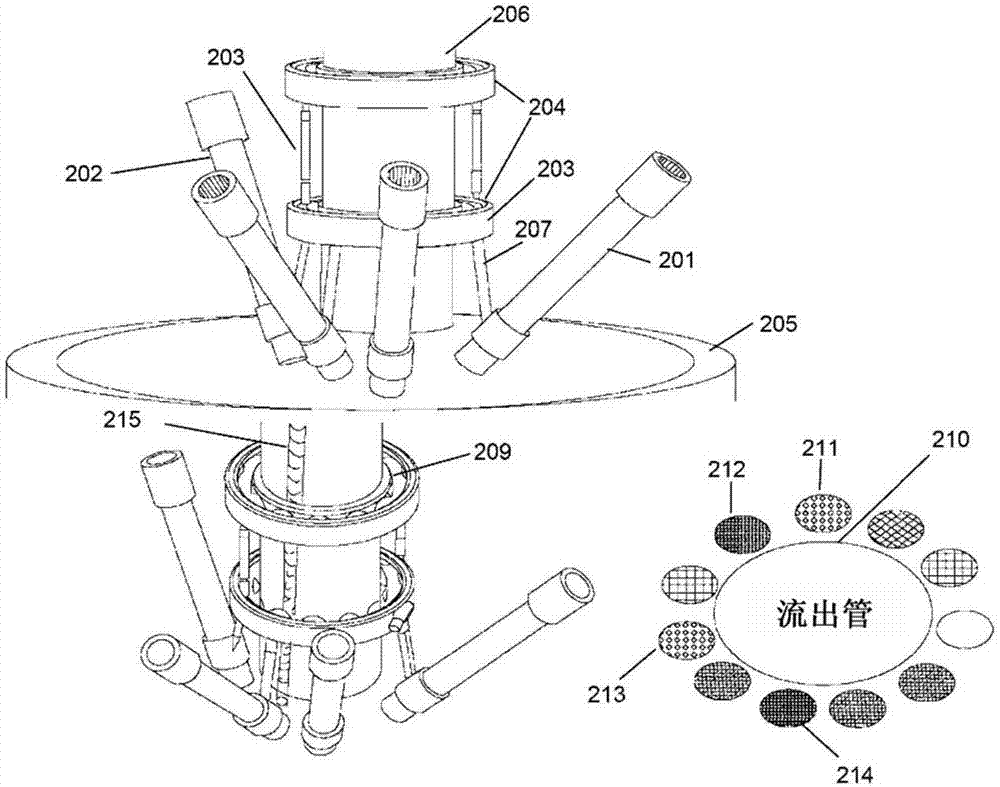

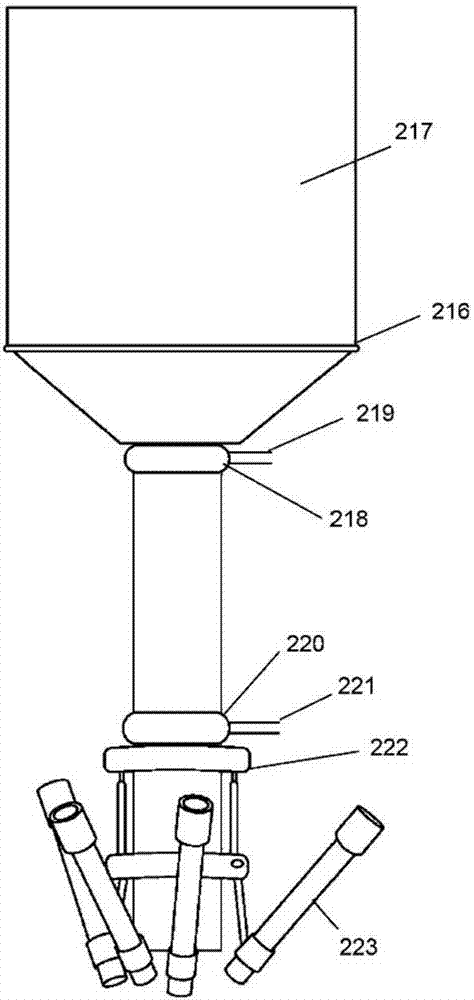

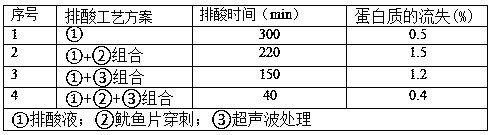

Method for preparing squid product

The invention provides a method for preparing squid products. The method of preparing the squid products includes the steps of pretreatment of squids, fish perforation, acid discharge, seasoning, coldair drying, quantity fixing, vacuum packaging and mild sterilization. The method of preparing the squid products has the advantages of increasing contact surfaces of acid-discharging liquid and the fish fillets after the squid fillets are punctured, speeding up the infiltration of the acid-discharging liquid into squid meat, promoting the destruction of a myofibril structure in the squids with varying pressure and the role of ultrasound by means of ultrasonic assisted variable pressure rolling to treat the squids, allowing acid in the cells of the products to flow out easily, promoting sodiumlactate and potassium carbonate in the acid-discharging liquid to fast and uniformly infiltrate into the squid meat with cavitation and mechanical effects of ultrasonic waves, effectively improving the acid discharge rate of the squids through synergistic effect of the squid fillets, acid-discharging liquid, vacuum and ultrasonic assistance, improving acid removal efficiency, shortening time andreducing protein loss.

Owner:NINGDE CITY YUEHAI AQUATIC PROD

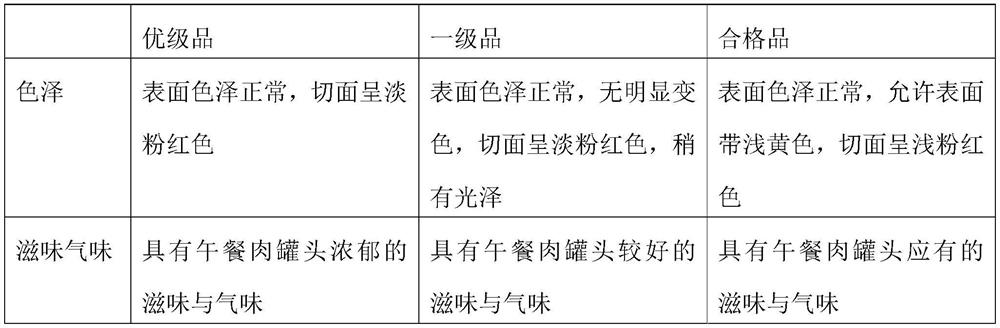

Canned luncheon meat and preparation method thereof

PendingCN112471433AEasy to operateDoes not affect normal workBeating-based meat tenderisingFood ingredientsBiotechnologyMonosodium glutamate

The invention discloses canned luncheon meat and a preparation method thereof in the field of foods. According to the invention, frozen pork, ice water, vegetable protein, starch, edible salt, white sugar, monosodium glutamate, spices and the like are used as raw materials, a unique double-rolling processing and wrapping type filling mode is adopted, and processes of vacuum mixing, high-temperature sterilization and the like are combined for production, so that the prepared luncheon meat product is rich in flavor and delicious in taste. The finished product has the advantages of compact and tender texture, high elasticity, uniform texture, no bleeding, no fat and jelly precipitation and excellent quality, and the content of auxiliary material blocks with the particle size of more than or equal to 0.5 mm in the finished product is lower than 0.2%.

Owner:CHONGQING YUANXIANG FOOD

Processing method of candied strawberries

The present invention discloses a processing method of candied strawberries. The method comprises the following steps: (1) selecting fresh strawberries, using a needle to puncture 10-15 holes on eachstrawberry, and carrying out vacuum microwave drying until the water content of the fruit is 50-70% by weight; (2) placing the strawberries in a sugar infiltration solution, and carrying out the firstvacuum sugar infiltration seasoning; (3) taking out the strawberries, then putting the strawberries into a sugar infiltration solution, carrying out the second vacuum sugar infiltration seasoning, and conducting sugar infiltration for 20-30 hours at normal temperature and normal pressure; (4) draining off sugar solution stuck on the surface of the strawberries to obtain semi-finished strawberries; and (5) putting the semi-finished strawberries into a blowing drying oven, firstly conducting drying at 65-70 DEG C for 3-4 hours, then keeping the drying suspended for 8-10 hours, then conducting drying at 55-60 DEG C for 4-5 hours to obtain the candied strawberries, putting the candied strawberries in a plastic film for 3-4 days for softening, and then carrying out vacuum packaging to obtain the finished product. According to the processing method provided by the invention, the processed strawberries are unique in flavor, bright in color, good in taste and rich in nutrients.

Owner:TIANE COUNTY PINGCHANG ECOLOGICAL AGRI

Production method of sausage

InactiveCN110074348AEvenly seasonedGuaranteed tasteClimate change adaptationFood preservationPreservative freeAdditive ingredient

The invention discloses a production method of a sausage. The production method of the sausage comprises the working procedures of ingredient selecting, cutting, seasoning preparing, mixing, casing preparing, stuffing, airing, packaging and storing. During production, firstly, pork is curt into diced pork, then after seasonings and the diced pork are mixed evenly, salting is conducted for 2-4 hours, then stuffing is conducted, thus the diced pork is evenly seasoned, the state of the sausage is guaranteed, and the seasonings do not contain preservatives or additives, so that the sausage is healthy and delicious; during stuffing, a casing is knotted every 20-25 cm, by fixing the casing by the casing, the problem that traditional fixing by means of wires is not sanitary can be solved, duringstuffing, small holes are formed in the casing every 1-2 cm by means of a fine needle, and the small holes benefit discharge of air in the sausage and evaporation of moisture in the sausage, so that the sausage is stuffed evenly and fully; after stuffing is conducted, airing is conducted for 3-6 days, so that the pork state can be guaranteed, and the problem of dry taste due to excessive airing issolved; and a vacuum package benefits long-term preservation.

Owner:江苏华伯食品产业发展有限公司

Multi-flavored dried sweet potato processing complete device

The present invention relates to a multi-flavored dried sweet potato processing complete device and belongs to the technical fields of multi-flavored dried sweet potato processing complete devices. The multi-flavored dried sweet potato processing complete device comprises a working table and a heating box body. A high temperature resistant belt conveyor is arranged horizontally on the working table and a conveying part of the belt conveyor is arranged within the heating box body. A material inlet is arranged at the left side of the heating box body and a material outlet is arranged at the right side of the heating box body. Two partition plates are arranged at the upper half part of the heating box body from left to right successively and divide the upper half of the heating box body into three heating zones with three different temperatures. Three electric heaters which independently control the temperature are arranged within the heating zones respectively. A mixing tank is connected to the material outlet, a stirrer is arranged on the mixing tank, the mixing tank is arranged on the working table, a feeding funnel used for seasoning is arranged at the top of the mixing tank, and a filter sieve is arranged right under a material outlet of the bottom part of the mixing tank. The multi-flavored dried sweet potato processing and screening complete device is very suitable for large-scale production, the device cost is low, the maintenance is easy, the occupation area is small, and the production efficiency is high.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

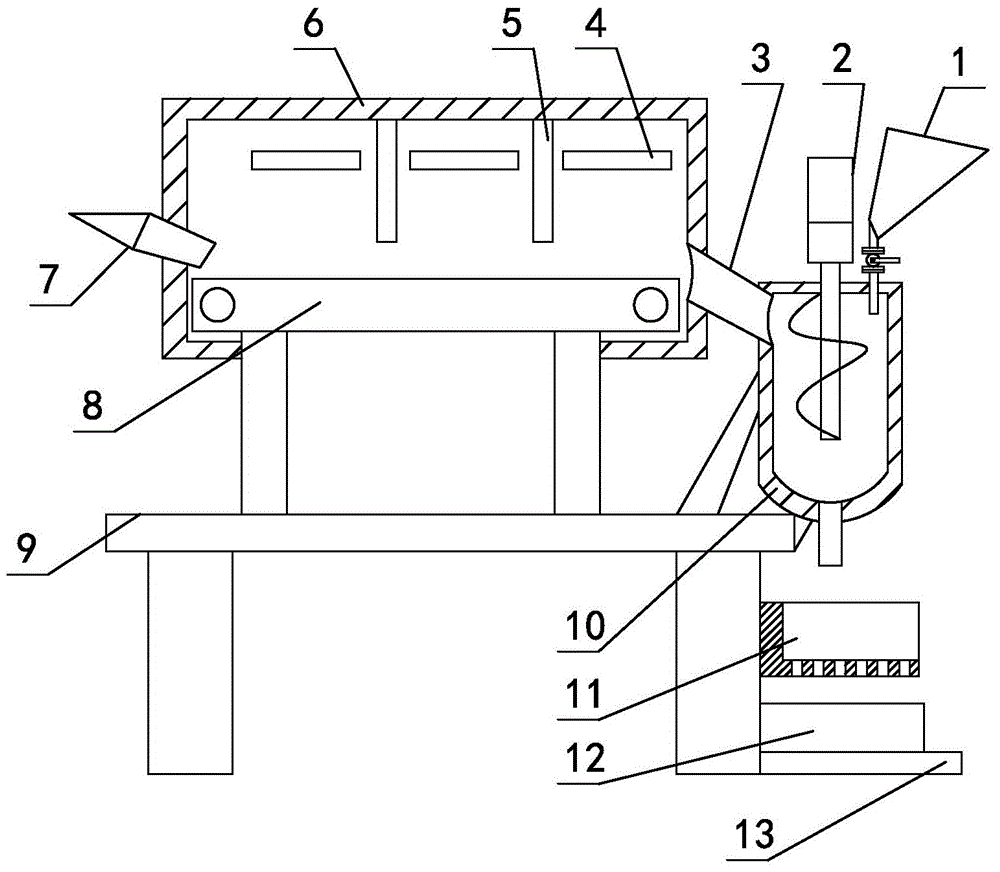

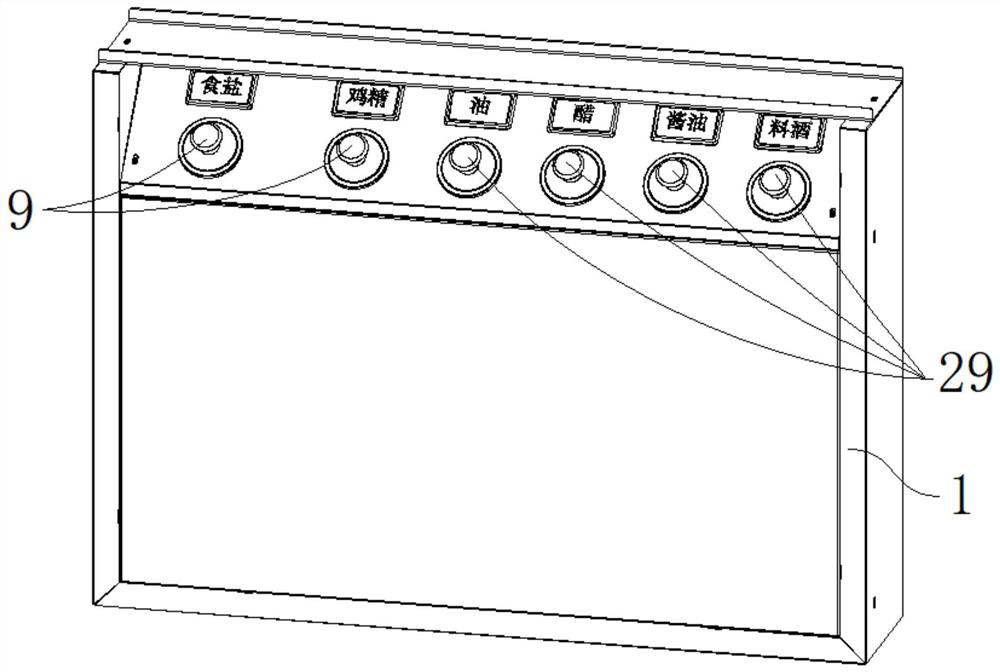

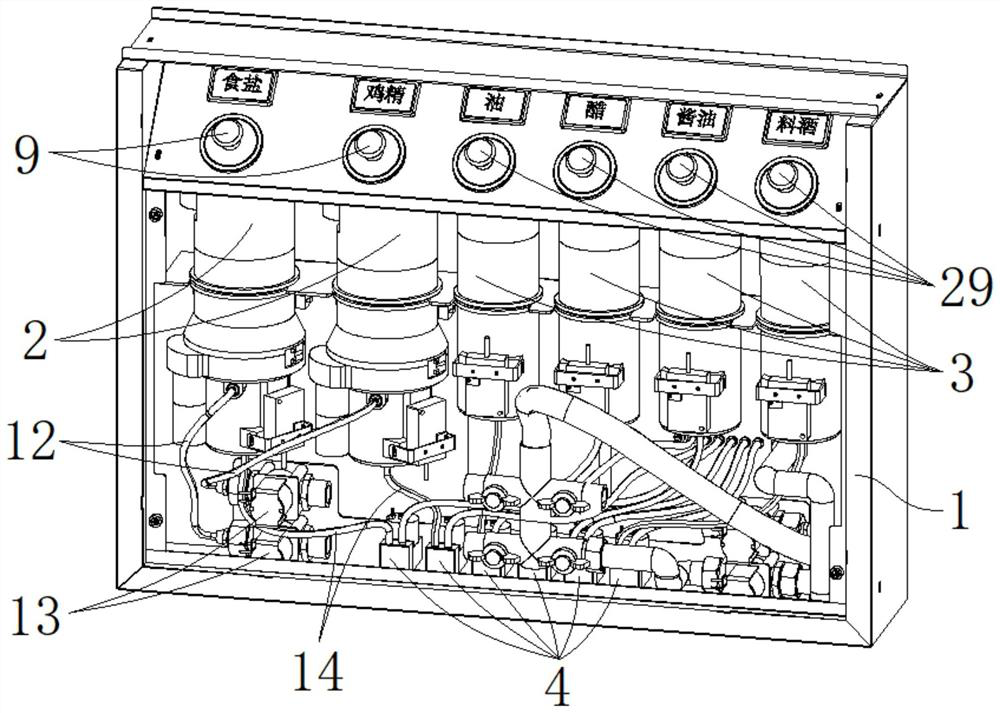

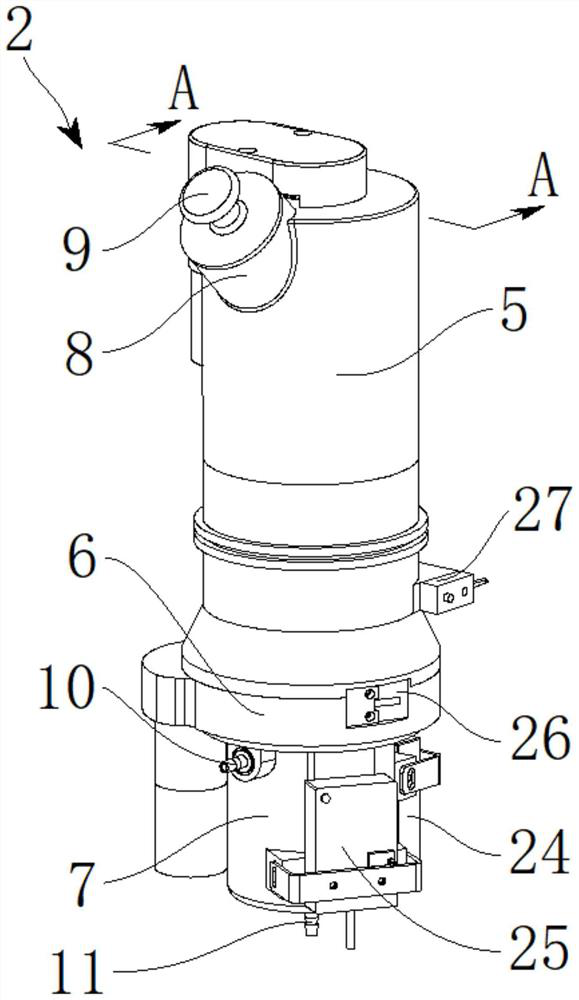

Powder bottle, intelligent seasoning adding device, powder seasoning adding method and computer readable storage medium

The invention provides a powder bottle which comprises a storage part used for storing powder seasonings and a discharge port used for discharging, and further comprises a mixing part communicated with the storage part. The discharge port is formed in the mixing part, a water inlet is formed in the mixing part, the powder seasonings stored in the storage part fall into the mixing part to be mixedwith water entering from the water inlet and then are discharged through the discharge port. Due to the fact that the powder seasoning stored in the storage part falls into the mixing part, is mixed with water entering from the water inlet and then is discharged through the discharge port, seasoning mixed liquid is discharged into the cooking utensil, the seasoning mixed liquid can be evenly attached to dishes in the cooking utensil, and therefore the dishes can be evenly seasoned.

Owner:GUANGZHOU FUGANG WANJIA INTELLIGENT TECH CO LTD

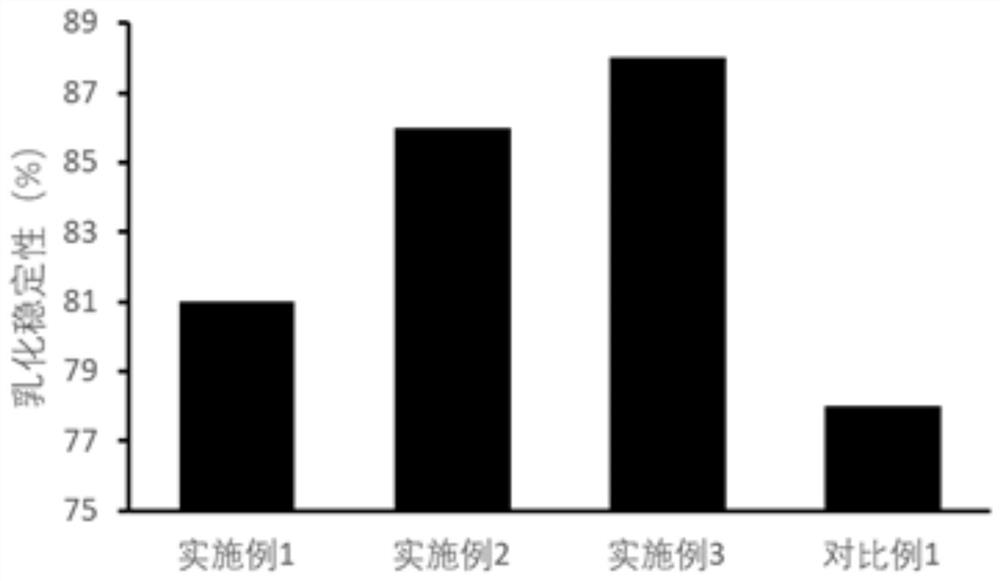

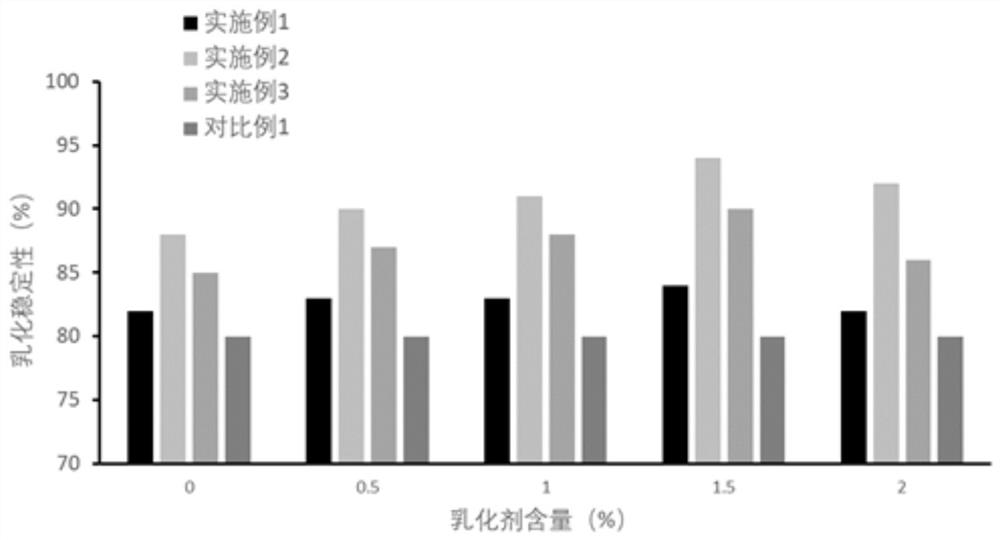

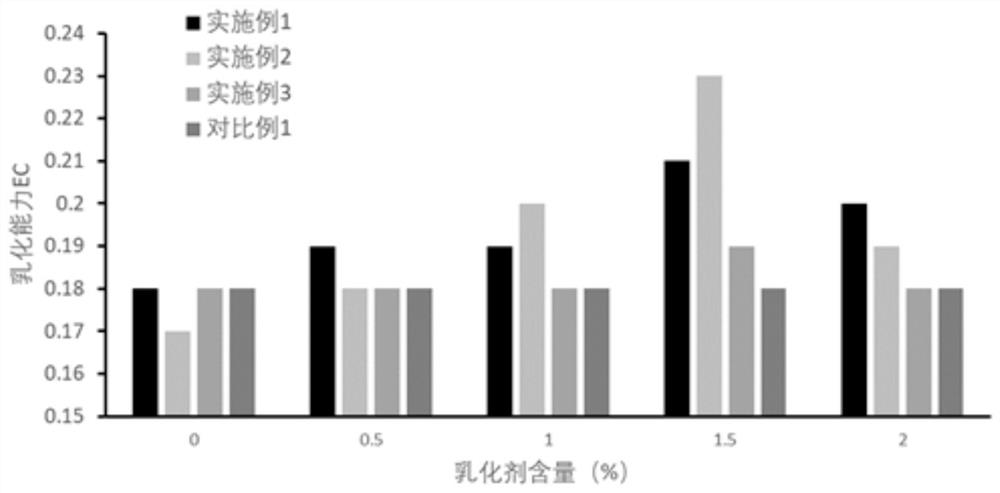

Emulsifying method of spice oleoresin

InactiveCN113273682AGood dispersionUniform food sensoryCosmetic preparationsMixing methodsBiotechnologySodium phosphates

The invention discloses a method for emulsifying spice oleoresin, which comprises the following steps of: crushing spices, preparing oleoresin by adopting a Soxhlet extraction method, diluting the obtained oleoresin by using a small amount of edible ethanol, ultrasonically dissolving to preparing 50% (v / v) oleoresin ethanol solution; Mixing sodium pyrophosphate, an emulsifier, edible gelatin and deionized water, fully dissolving, cooling to room temperature, adding an oleoresin ethanol solution and table salt, stirring for 2 minutes, and finally emulsifying to form a uniformly dispersive emulsion. The spice oleoresin prepared by the process disclosed by the invention is used as a raw material, an emulsifier and a stabilizer in a specific proportion are added, and emulsifying and dispersing to prepare a uniform emulsion, so that a flavoring component is easy to disperse in an aqueous solution and can be better used for liquid seasoning, the flavoring component is ensured to be more uniform in food sense and aroma distribution in a food system, and the food is endowed with richer taste. The subsequent seasoning is more uniform and thorough, the seasoning is fast, and the pickling time is shortened.

Owner:四川省雅士科技有限公司

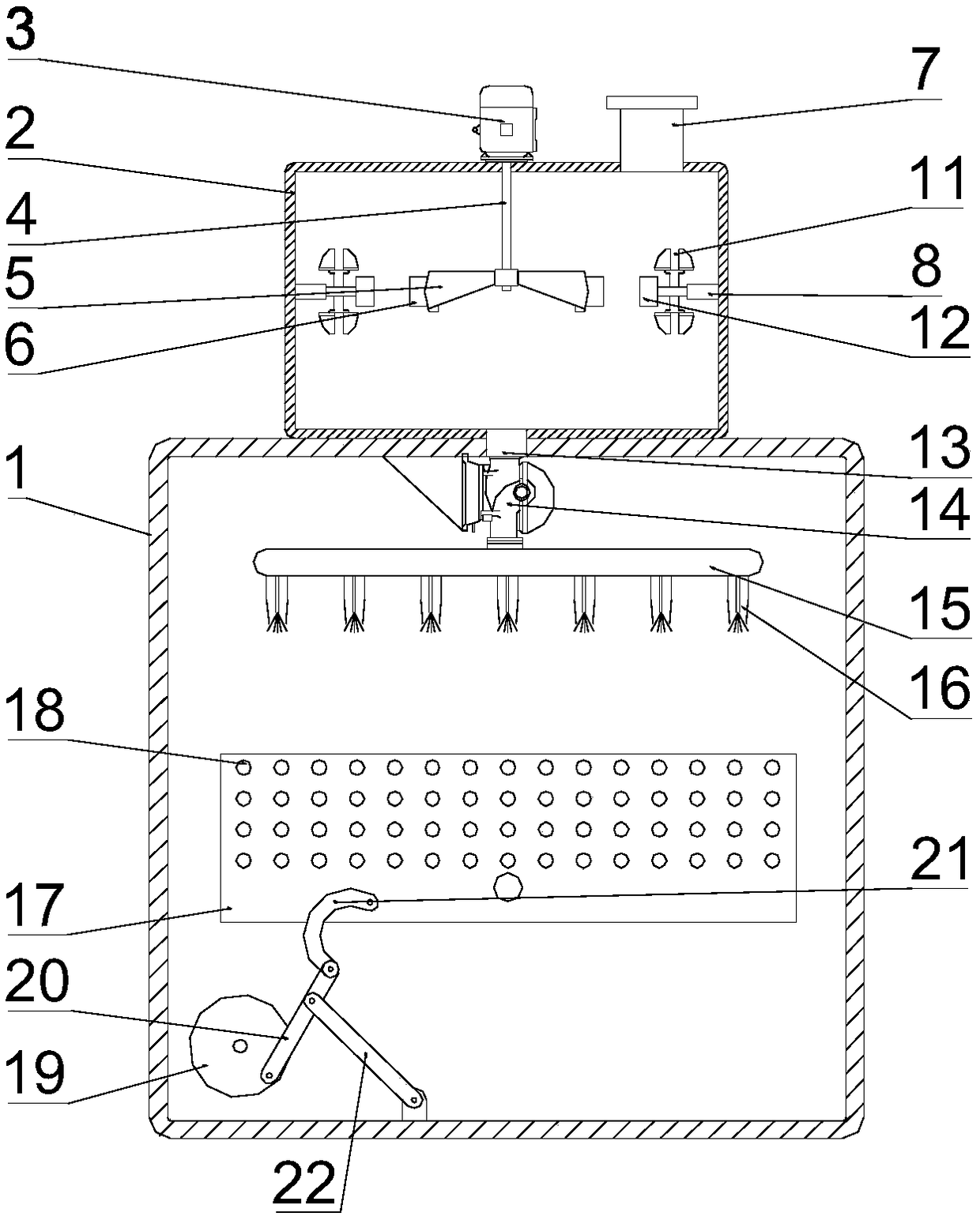

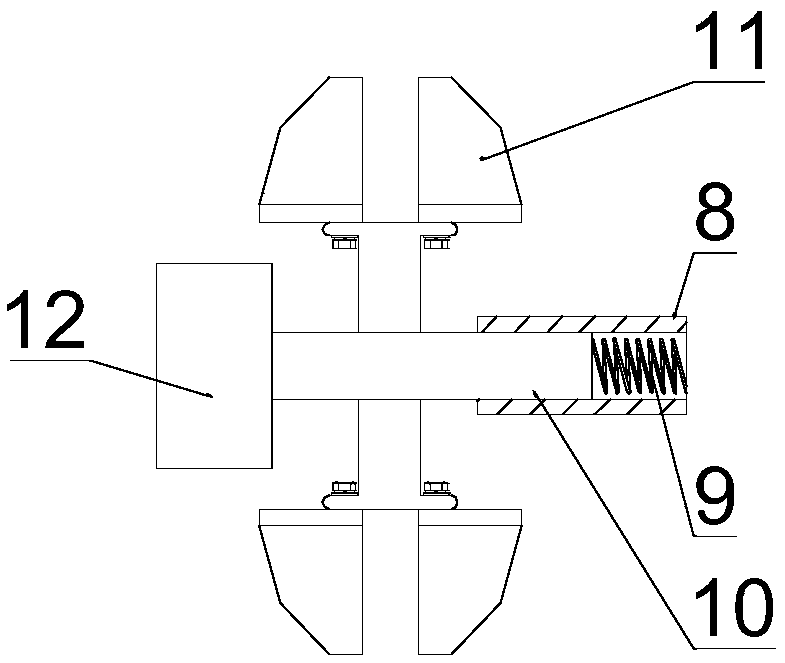

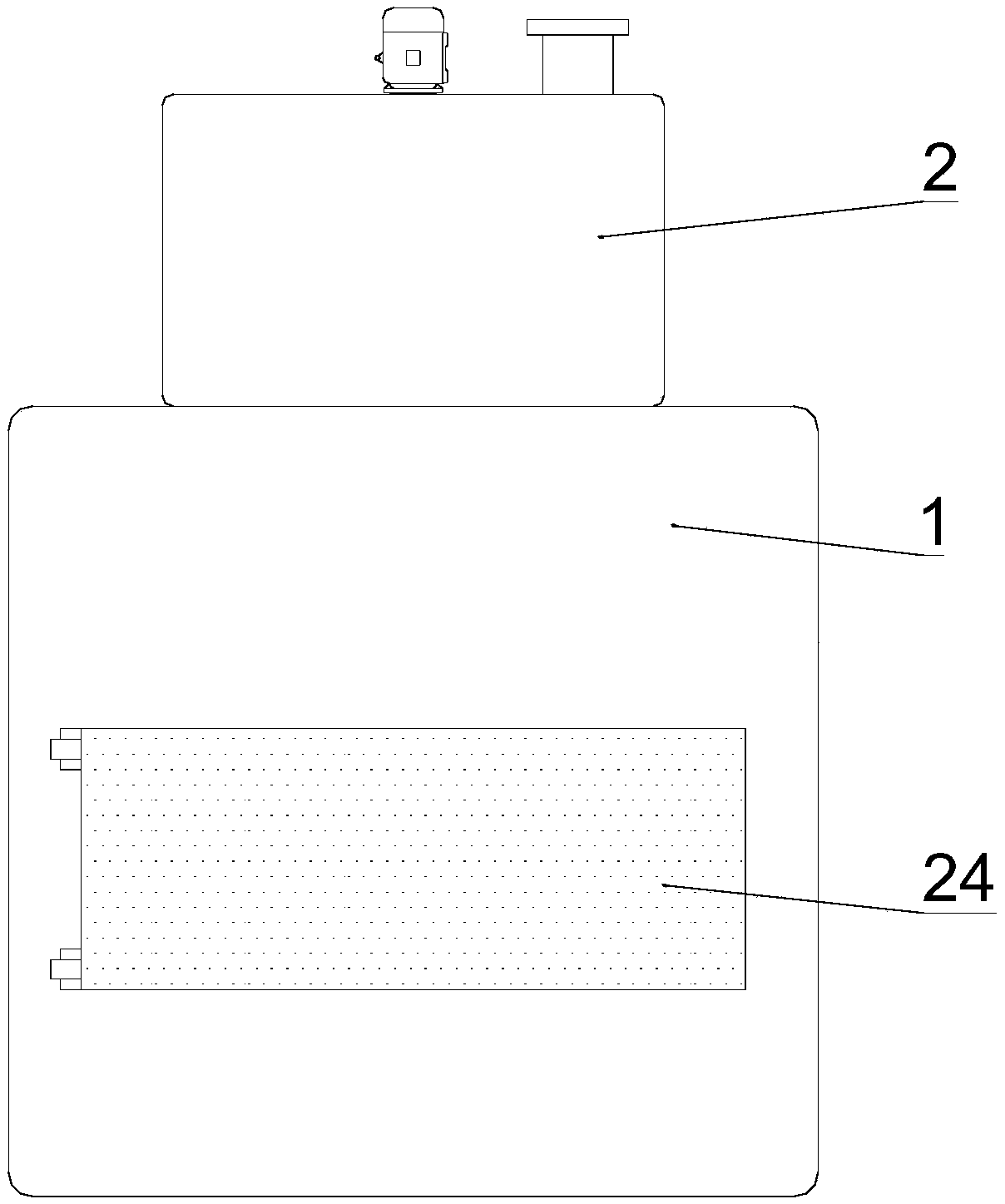

Seasoning spraying device for conch flesh pickling processing

InactiveCN109090510ATo achieve the purpose of reciprocating movementFully homogeneousRotary stirring mixersTransportation and packagingConchReciprocating motion

The invention discloses a seasoning spraying device for conch flesh pickling processing and relates to the technical field of food processing. The seasoning spraying device comprises a spraying box, wherein the lower side of the inside of the spraying box is provided with a seasoning wrapping box with an open upper end. A second motor rotates to drive agitator blades to rotate, the magnetic effectof an iron block and a magnet makes a movable column in an elastic telescopic device to extend out, a material pushing plate is driven to move, accordingly the purpose of reciprocating motion of thematerial pushing plate is achieved, seasoning liquid located in the seasoning box is fully homogenized, the concentration of sprayed seasoning is uniform, and the product quality is improved. Due to the fact a first motor rotates to drive a rotary table to rotate, the seasoning wrapping box performs reciprocating swinging under the driving effect of a first connecting rod, an arc-shaped rod and asecond connecting rod. Therefore, the seasoning wrapping box perform reciprocating swinging, accordingly conch flesh located in the seasoning wrapping box also swings in a following way, the front faces and back faces of the conch flesh can wrap seasonings, the product quality is further improved, and the seasonings wrapping the surfaces of the conch flesh are uniform.

Owner:李伟

Drying and processing complete equipment for multi-flavor dried sweet potatoes, with heat-insulating and mixing mechanism

The invention relates to drying and processing complete equipment for multi-flavor dried sweet potatoes, with a heat-insulating and mixing mechanism, and belongs to the technical field of drying of dried sweet potatoes. The drying and processing complete equipment comprises a mixing tank, wherein two working tables and two heating box bodies are respectively arranged on the left side and the right side of the mixing tank, and a belt conveyor is horizontally mounted on each of the working tables; two partition boards are sequentially arranged at the upper half part in each of the heating box bodies from left to right, and the upper half part of each of the heating box bodies is divided into three heating zones with different temperatures through the two corresponding partition boards; an electric heater of which the temperature is independently controlled is mounted in each of the heating zones, and a feed hopper for seasoning is mounted at the top of the mixing tank; a filter sieve is arranged just below a discharge opening in the bottom of the mixing tank, and a seasoning receiving tank is formed just below the filter sieve and is independently placed on a laying plate; the filter sieve and the laying plate are both fixed to the working tables; a steam jacket layer is arranged on the outside wall of the mixing tank, and barrier strips are spirally arranged on the inside wall of the mixing tank; and the upper ends of the barrier strips are located below the discharge opening. The drying and processing complete equipment disclosed by the invention realizes continuous operation and is very high in yield.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

Steam style dried sweet potato processing device with seasoning, heat preserving and mixing mechanisms

InactiveCN105614918AAccelerated mixing and uniform cooling effectEvenly seasonedFood processingFood treatmentProcess engineeringHeat sink

The present invention relates to a steam style dried sweet potato processing device with seasoning, heat preserving and mixing mechanisms and belongs to the technical field of dried sweet potato processing. The processing device consists of a working table and a heating box body. A material outlet is arranged at the right side of the heating box body, two partition plates are arranged within the heating box body and divide the upper half of the heating box body into three heating zones with three different temperatures, steam cooling fins are arranged within each heating zone, dispersion plates are arranged horizontally within the heating zones under each of the steam cooling fins, and three fans are arranged respectively above each of the steam cooling fins within the heating zones. A mixing tank is connected to the material outlet, a stirrer is arranged on the mixing tank, a material adding funnel used for seasoning is arranged at the top of the mixing tank, a steam jacket layer is arranged on the outside wall of the mixing tank, and baffle bars are spirally arranged on the inside wall of the mixing tank. By ensuring the advantages of the original design, the uniform mixing and temperature lowering effects of the dried sweet potatoes are accelerated, and the device is very conducive to large-scale production management.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

Steam-type dried sweet potato production equipment with seasoning function

The invention relates to steam-type dried sweet potato production equipment with a seasoning function and belongs to the technical field of steam-type dried sweet potato production equipment with the seasoning function. The steam-type dried sweet potato production equipment with the seasoning function comprises a workbench and a heating box; a high-temperature-resistant belt conveyor is horizontally installed on the workbench; the conveying part of the belt conveyor is arranged in the heating box; a material inlet is arranged at the left side of the heating box; a material outlet is arranged at the right side of the heating box; two clapboards are orderly arranged at the upper half part of the interior of the heating box from the left to the right, so that the upper half part of the heating box is divided into three heating areas of different temperatures by the clapboards; a steam heat sink is installed in each heating area; the adjacent steam heat sinks are connected and communicated by pipelines; a mixing tank is connected to the material outlet; a stirrer is installed on the mixing tank; the mixing tank is installed on the workbench; and a material-loading hopper for seasoning is installed at the top of the mixing tank. The steam-type dried sweet potato production equipment with the seasoning function is especially suitable to scale production; and the steam-type dried sweet potato production equipment with the seasoning function has the advantages of low equipment cost, convenient maintenance, small floor area and high production efficiency.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

Processing and screening equipment for multi-flavor dried sweet potatoes, with heat-insulating and mixing mechanism

InactiveCN106307239AMeet the mixing volume requirementsEvenly seasonedSievingScreeningFlavorEngineering

The invention relates to processing and screening equipment for multi-flavor dried sweet potatoes, with a heat-insulating and mixing mechanism, and belongs to the technical field of processing of dried sweet potatoes. The processing and screening equipment comprises a mixing tank, wherein two working tables and two heating box bodies are respectively arranged on the left side and the right side of the mixing tank, and a high-temperature-resistant belt conveyor is horizontally mounted on each of the working tables; two partition plates are sequentially arranged at the upper half part in each of the heating box bodies from left to right, and the upper half part of each of the heating box bodies is divided into three heating zones with different temperatures through the two corresponding partition plates; an electric heater of which the temperature is independently controlled is mounted in each of the heating zones, and a dissipation plate is horizontally arranged in the corresponding heating zone under each of the electric heaters, and a fan blowing downwards is arranged in the corresponding heating zone above each of the electric heaters; a feed hopper for seasoning is mounted at the top of the mixing tank, and a filter sieve is arranged just below a discharge opening in the bottom of the mixing tank; and a steam jacket layer is arranged on the outside wall of the mixing tank, and barrier strips are spirally arranged on the inside wall of the mixing tank. The processing and screening equipment disclosed by the invention realizes continuous operation and is very high in yield.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

Steam-type dried sweet potato manufacturing device with seasoning, heat preserving and mixing mechanisms

InactiveCN106306754AMeet the mixing volume requirementsEasy to adjustFood preparationLine tubingEngineering

The present invention relates to a steam-type dried sweet potato manufacturing device with seasoning, heat preserving and mixing mechanisms and belongs to the technical field of dried sweet potato manufacturing. The dried sweet potato manufacturing device comprises a mixing tank, two working tables and two heating box bodies arranged at the left and right side of the mixing tank. One high temperature resistant belt conveyor is arranged horizontally on each of the working tables respectively. Two partition plates are successively arranged at the upper half part of the interior of each of the heating box bodies from left to right and divide the upper half part of each of the heating box bodies into three heating zones with three different temperatures. Steam cooling fins are arranged within each of the heating zones, the adjacent steam cooling fins communicate with each other via pipeline connections, steam inlet pipelines are connected to the steam cooling fins at the most right sides, and steam outlet pipelines are connected to the steam cooling fins at the most left sides. A material feeding funnel is arranged at the top part of the mixing tank, a steam jacket layer is arranged at the outside wall of the mixing tank, a baffle bar is spirally arranged on the inside wall of the mixing tank, and the upper end of the baffle bar is located at the lower side of a material outlet. The dried sweet potato manufacturing device realizes a continuous operation and is very high in yields.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com