Emulsifying method of spice oleoresin

A spice oil and oleoresin technology, which is applied in chemical instruments and methods, mixing methods, inactive ingredients of oil/fat/wax, etc., can solve the problems of powder product caking, difficulty in weighing and adding raw materials, etc. , to achieve the effect of uniform and thorough seasoning, uniform food sensory and aroma distribution, and quick taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

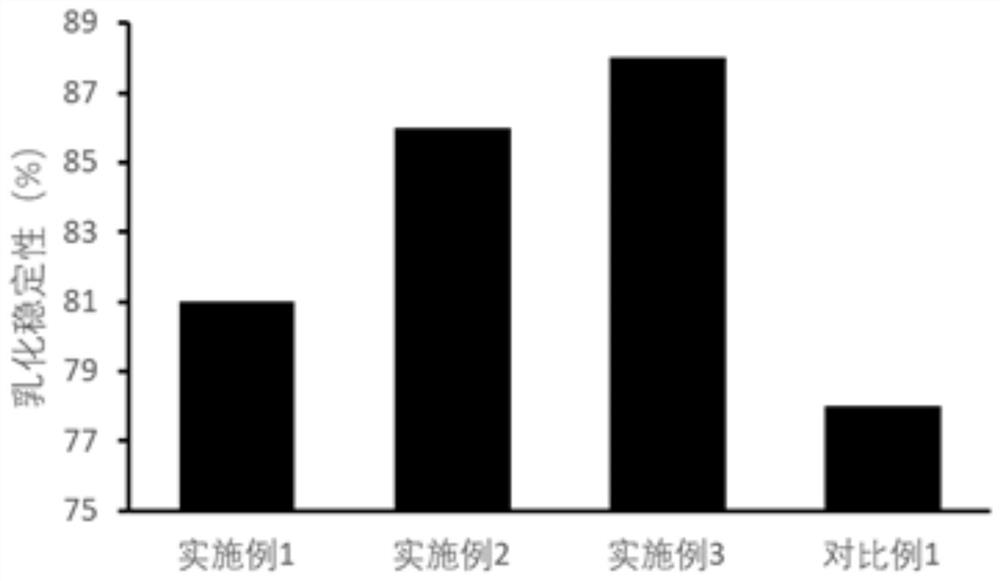

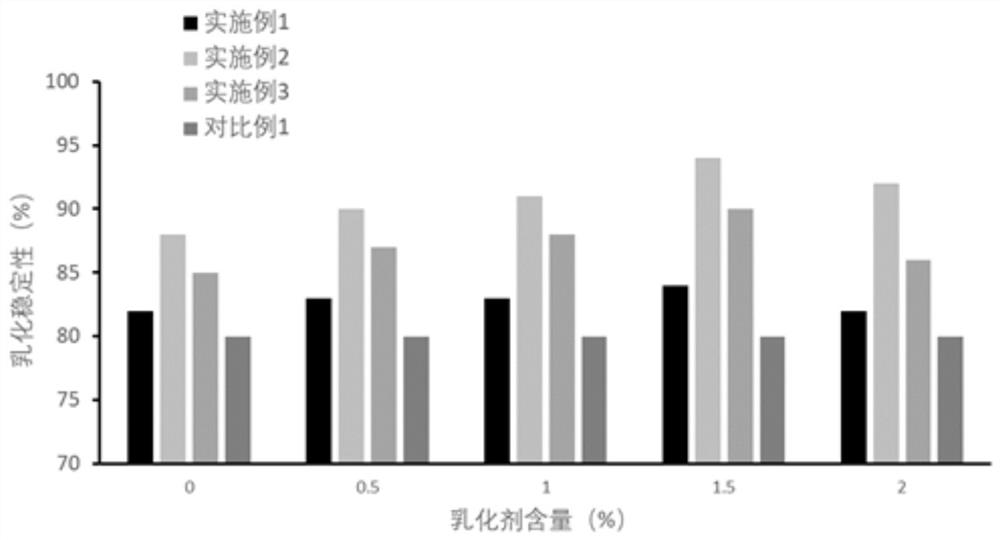

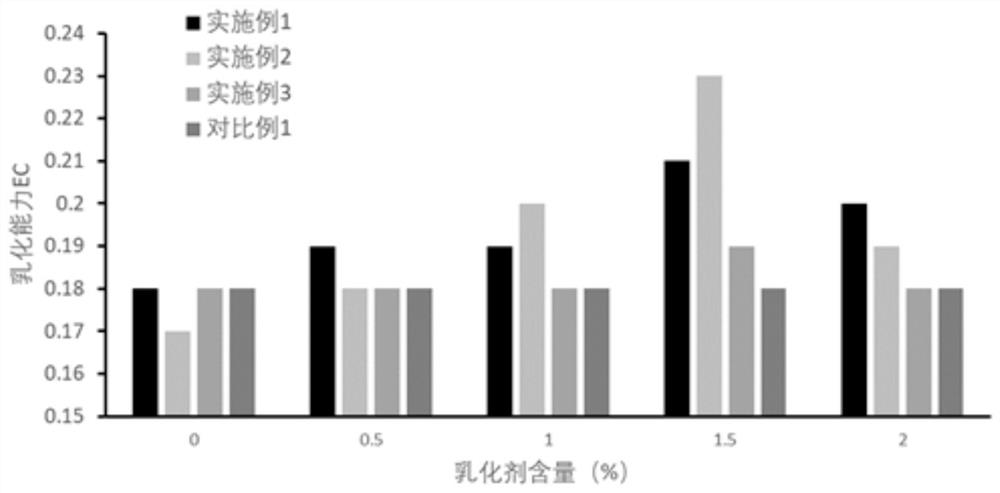

Embodiment 1

[0041] A kind of emulsification method of spice oleoresin, taking star anise as example:

[0042] (1) Preparation of oleoresin: crush the star anise and pass through a 100-mesh sieve, add a 95% ethanol solution with a ratio of material to agent (g / mL) of 15:100 (star anise: ethanol solvent), and reflux for 3 hours. The extract was washed three times with ethanol, the combined extracts were concentrated, washed three times with petroleum ether, and the solvent was evaporated to obtain the oleoresin of yellow-brown paste.

[0043] (2) Preparation of oleoresin emulsion: Dilute the star anise oleoresin obtained in step (1) with a small amount of 95% edible ethanol, ultrasonically treat it for a certain period of time to fully dissolve it, and make 50% (w / v) oil Resin ethanol solution. Add 0.12% sodium pyrophosphate and 0.1% edible gelatin to dissolve in 100mL deionized water at 60~70℃, stir to fully dissolve, add 6% oleoresin ethanol solution and 1% salt after cooling to room tem...

Embodiment 2

[0045] A kind of emulsification method of spice oleoresin, taking star anise as example:

[0046] (1) Preparation of oleoresin: crush the star anise and pass through a 100-mesh sieve, add a 95% ethanol solution with a ratio of material to agent (g / mL) of 15:100 (star anise: ethanol solvent), and reflux for 3 hours. The extract was washed three times with ethanol, the combined extracts were concentrated, washed three times with petroleum ether, and the solvent was evaporated to obtain the oleoresin of yellow-brown paste.

[0047] (2) Preparation of oleoresin emulsion: Dilute the star anise oleoresin obtained in step (1) with a small amount of 95% edible ethanol, ultrasonically treat it for a certain period of time to fully dissolve it, and make 50% (w / v) oil Resin ethanol solution. Add 0.12% sodium pyrophosphate and 0.15% edible gelatin to dissolve in 100mL deionized water at 60~70℃, stir to dissolve them fully, add 6% oleoresin ethanol solution and 1% salt after cooling to ro...

Embodiment 3

[0049] A kind of emulsification method of spice oleoresin, taking star anise as example:

[0050] (1) Preparation of oleoresin: crush the star anise and pass through a 100-mesh sieve, add a 95% ethanol solution with a ratio of material to agent (g / mL) of 15:100 (star anise: ethanol solvent), and reflux for 3 hours. The extract was washed three times with ethanol, the combined extracts were concentrated, washed three times with petroleum ether, and the solvent was evaporated to obtain the oleoresin of yellow-brown paste.

[0051] (2) Preparation of oleoresin emulsion: Dilute the star anise oleoresin obtained in step (1) with a small amount of 95% edible ethanol, ultrasonically treat it for a certain period of time to fully dissolve it, and make 50% (w / v) oil Resin ethanol solution. Add 0.12% sodium pyrophosphate and 0.2% edible gelatin to dissolve in 100mL 60~70℃ deionized water, stir to dissolve them fully, add 6% oleoresin ethanol solution and 1% salt after cooling to room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com