Method for preparing squid product

A technology of squid and products, applied in the direction of food science, etc., to achieve the effect of instant convenience and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

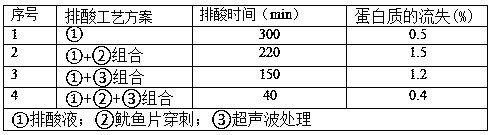

Method used

Image

Examples

Embodiment 1

[0023] (1) Raw material pretreatment: Thaw the frozen squid at 4°C for 11 hours, wash the surface dirt with clean water and set aside; cut into slices according to customer requirements, and make them into lengths of 5-8cm, width of 3-6cm, and thickness of 0.5- 2cm block, spare;

[0024] (2) Fish meat perforation: perforate the squid fish meat with one of needle perforation and laser perforation, the micro-hole distance is 1 mm, and the micro-hole diameter is 0.2 mm;

[0025] (3) Acid discharge: Put the punctured squid slices into the acid discharge liquid at a weight ratio of squid:acid discharge liquid of 1:2, so that it is in an ultrasonic environment with a frequency of 17KHz and a power of 35W, and treat it for 25s; Two-stage treatment: make it in the ultrasonic environment with frequency of 25KHz and power of 55W for 25s; then unidirectional continuous vacuum tumbling for 9 minutes under vacuum degree of 0.06MPa, and then unidirectional continuous tumbling for 7 minutes ...

Embodiment 2

[0031] (1) Pretreatment of raw materials: thaw frozen squid at 3°C for 10 hours, wash off the surface dirt with water and set aside; slice according to customer requirements, and make 5-8cm long, 3-6cm wide, and 0.5-6cm thick 2cm block, spare;

[0032] (2) Fish meat perforation: perforate the squid fish meat with one of needle perforation and laser perforation, the micro-hole distance is 0.5 mm, and the micro-aperture diameter is 0.1 mm;

[0033] (3) Acid discharge: Put the punctured squid slices into the acid discharge liquid at a weight ratio of squid:acid discharge liquid of 1:1, and place them in an ultrasonic environment with a frequency of 15KHz and a power of 30W for 20s; Two-stage treatment: make it in the ultrasonic environment with a frequency of 20KHz and a power of 50W, and process for 20s; then under the condition of a vacuum of 0.03MPa, one-way continuous vacuum tumbling for 8 minutes, and then under normal pressure for one-way continuous tumbling for 6 minutes...

Embodiment 3

[0039] (1) Raw material pretreatment: Thaw the frozen squid at 4°C for 12 hours, wash the surface dirt with clean water and set aside; cut into slices according to customer requirements, and make them into lengths of 5-8cm, width of 3-6cm, and thickness of 0.5- 2cm block, spare;

[0040] (2) Fish meat perforation: perforate the squid fish meat with one of needle perforation and laser perforation, the micro-hole distance is 2 mm, and the micro-hole diameter is 0.2 mm;

[0041] (3) Acid discharge: Put the punctured squid slices into the acid discharge liquid at a weight ratio of squid:acid discharge liquid of 1:3, and place them in an ultrasonic environment with a frequency of 18KHz and a power of 40W for 30s; Two-stage treatment: make it in the ultrasonic environment with a frequency of 25KHz and a power of 60W, and process for 30s; then unidirectional continuous vacuum tumbling for 10 minutes under a vacuum degree of 0.09MPa, and then unidirectional continuous tumbling for 8 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com