Exhaust gas conveying pipe based on timing static electricity and ultrasonic dust removal

An ultrasonic and conveying pipe technology, applied in the field of environmental protection equipment, can solve the problems of easy blockage of pipelines, large space occupation, and need to stop, and achieve the effect of good anti-blocking effect, high intelligence and space reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

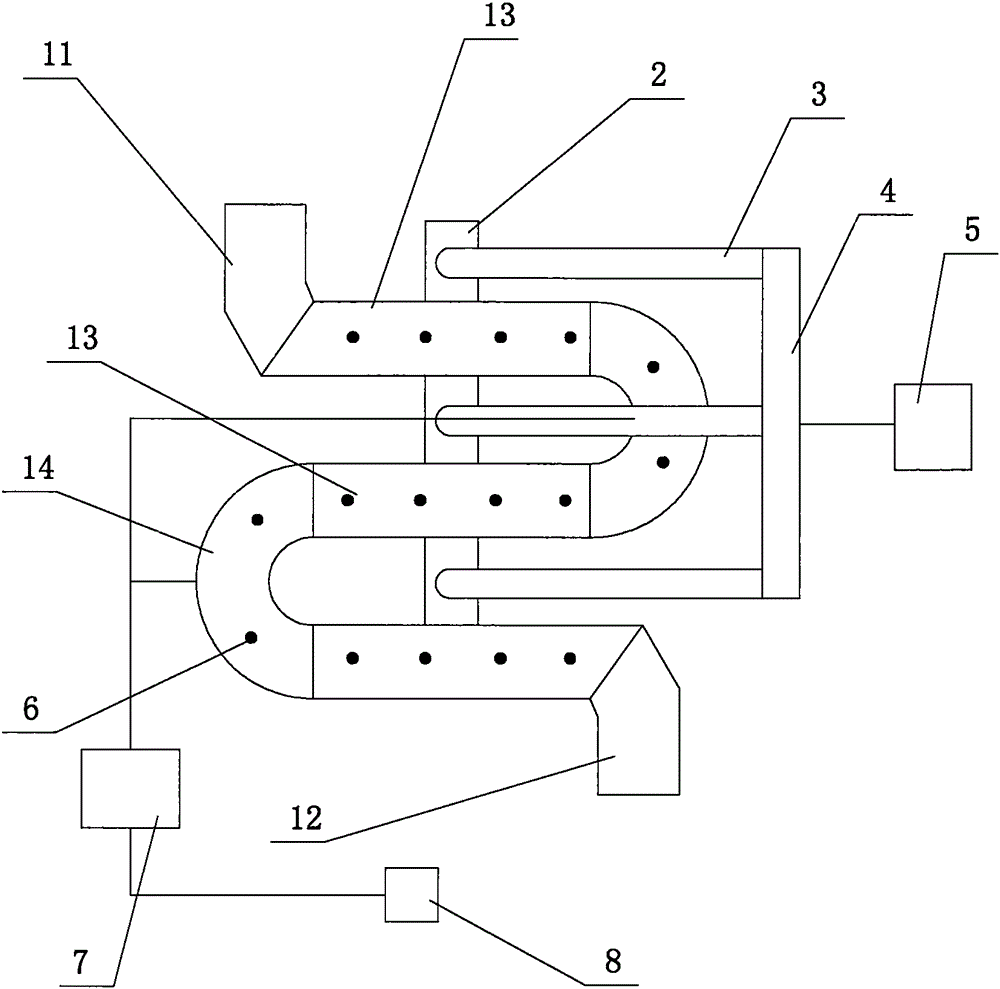

[0011] Such as figure 1 As shown, the exhaust gas delivery pipe based on timing electrostatic and ultrasonic dust removal in this embodiment includes a pipe body 1, and the two ends of the pipe body 1 are respectively equipped with an inlet pipe 11 and an air outlet pipe 12, and the pipe body 1 is a continuous bending structure , including upper and lower multi-layer horizontal tubes 13 and curved arc tubes 14 connected to the ends of the connected horizontal tubes 13; dust suction pipes 2 are installed between the upper and lower horizontal tubes 13, and the dust suction pipes 2 are connected to the dust guide pipes respectively. 3 are connected, and the dust guide pipe 3 is jointly connected with the dust suction main pipe 4, and the dust suction main pipe 4 is connected with the vacuum cleaner 5. The side walls of the horizontal tube 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com