Novel method for representing ultra-precision cutting surface grain-boundary relief

A cutting surface, ultra-precision technology, applied in the field of characterization of super-precision cutting surface grain boundary embossment, can solve the problem of being unable to distinguish the difference, and achieve the effect of reducing signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

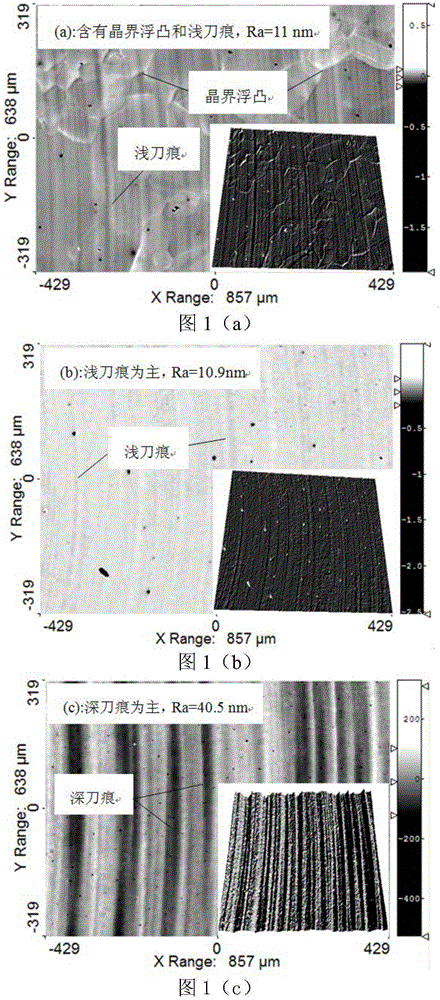

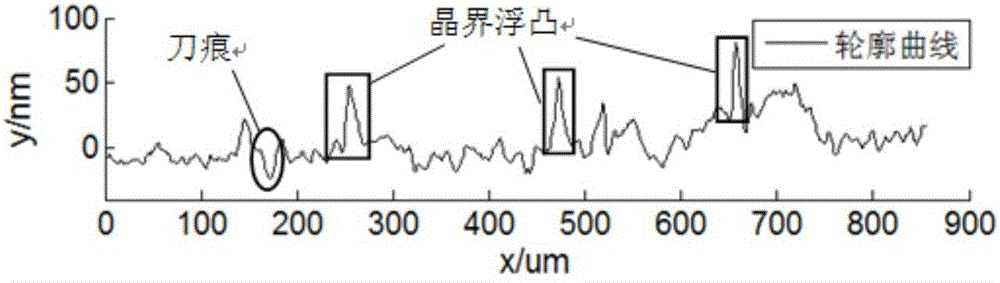

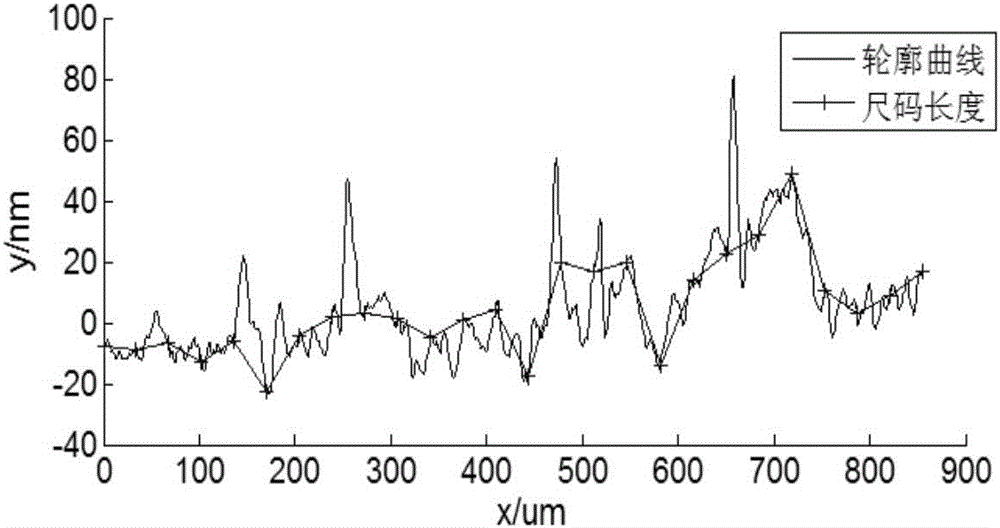

[0032] When cutting oxygen-free copper with single-point diamond, three different surfaces will be obtained according to different cutting parameters, such as figure 1 As shown, the three surfaces are represented as: figure 1 (a) It contains both shallow knife marks and embossed grain boundaries, and its cross-sectional contour line is as follows figure 2 , figure 1 (b) Contains only shallow knife marks, figure 1 (c) Contains only deep tool marks; the cutting parameters that can cause grain boundary embossment are generally: spindle speed 1000-1200r / min, depth of cut 1-5um, feed rate 1-2mm / min; The roughnesses were 11.0 nm, 10.9 nm, and 40.5 nm, respectively. figure 1 (a) with fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com