A special bolt dismounting and fixing device for a live working robot

A technology for live work and bolt disassembly is applied in the direction of manipulators, manufacturing tools, chucks, etc. It can solve problems that affect construction progress and work efficiency, work items cannot be completed, and bolts cannot be disassembled. It can reduce manual high-voltage belt work. Industrial projects, improve surface durability and aesthetics, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

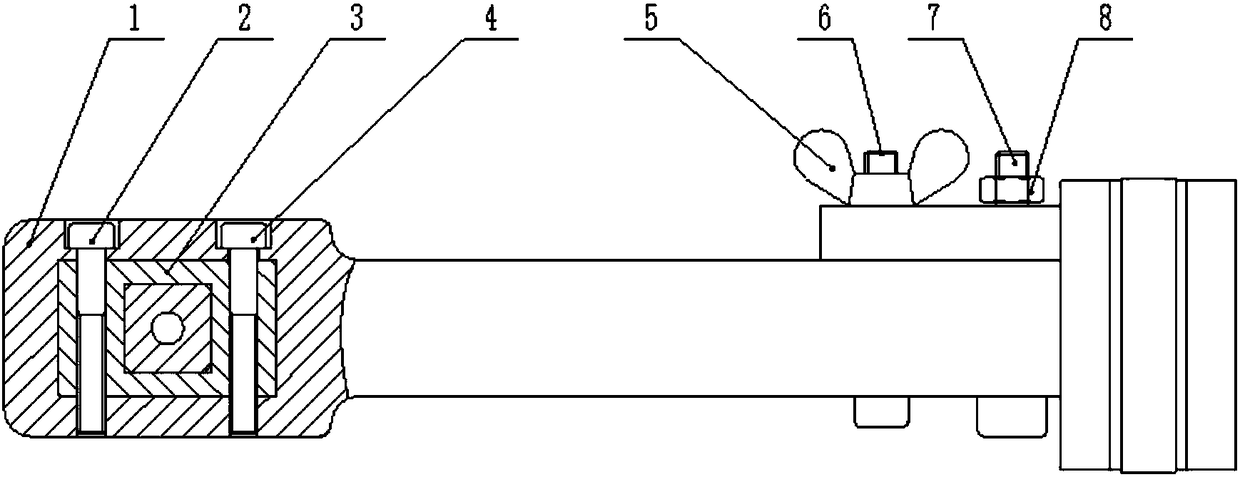

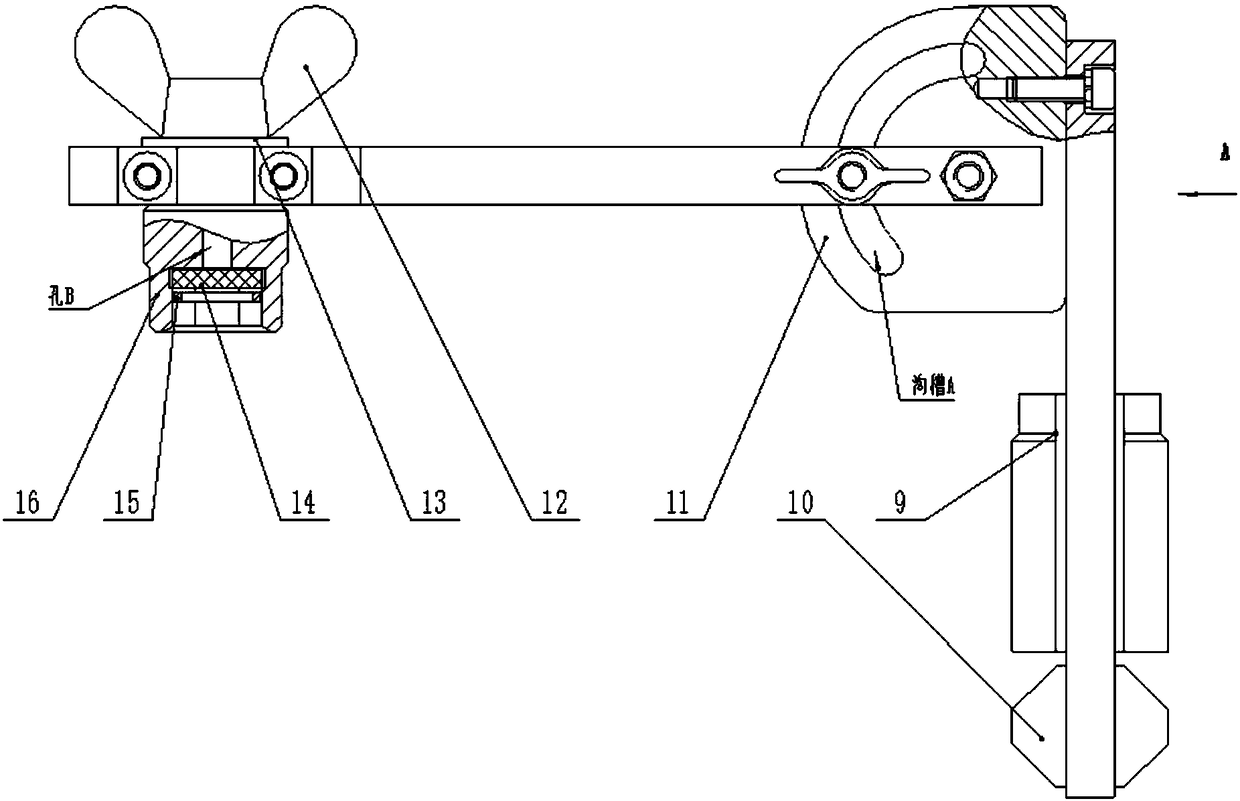

[0029] Such as Figure 1-2 As shown in the figure, a special bolt disassembly and fixing device for a live working robot is composed of a shaft sleeve assembly, a frame body assembly, a clamping body assembly, etc.;

[0030] Shaft sleeve assembly, including shaft sleeve 16, flat washer 13, second wing nut 12, magnet 14, hole retaining ring 15, etc., magnet 14 is put into the inner hole of shaft sleeve 16, and hole retaining ring 15 is put into the shaft In the groove of the inner hole of the sleeve 16, the sleeve 14 is inserted into the liner 3, the flat washer 13 is inserted into the thread of the shaft sleeve 14, and the liner 3 is pressed, and the second butterfly nut 12 is tightened to the thread of the sleeve 14. superior.

[0031] A magnet 14 is installed in the inner hole of the shaft sleeve 16, which can hold the bolt and prevent the bolt from falling off during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com