A reciprocating kiwi fruit slicer

A slicing device and kiwifruit technology, applied in metal processing and other directions, can solve the problems of concentrated pressing force on the contact surface, difficult to guarantee thickness consistency, time-consuming and labor-intensive, etc. Flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

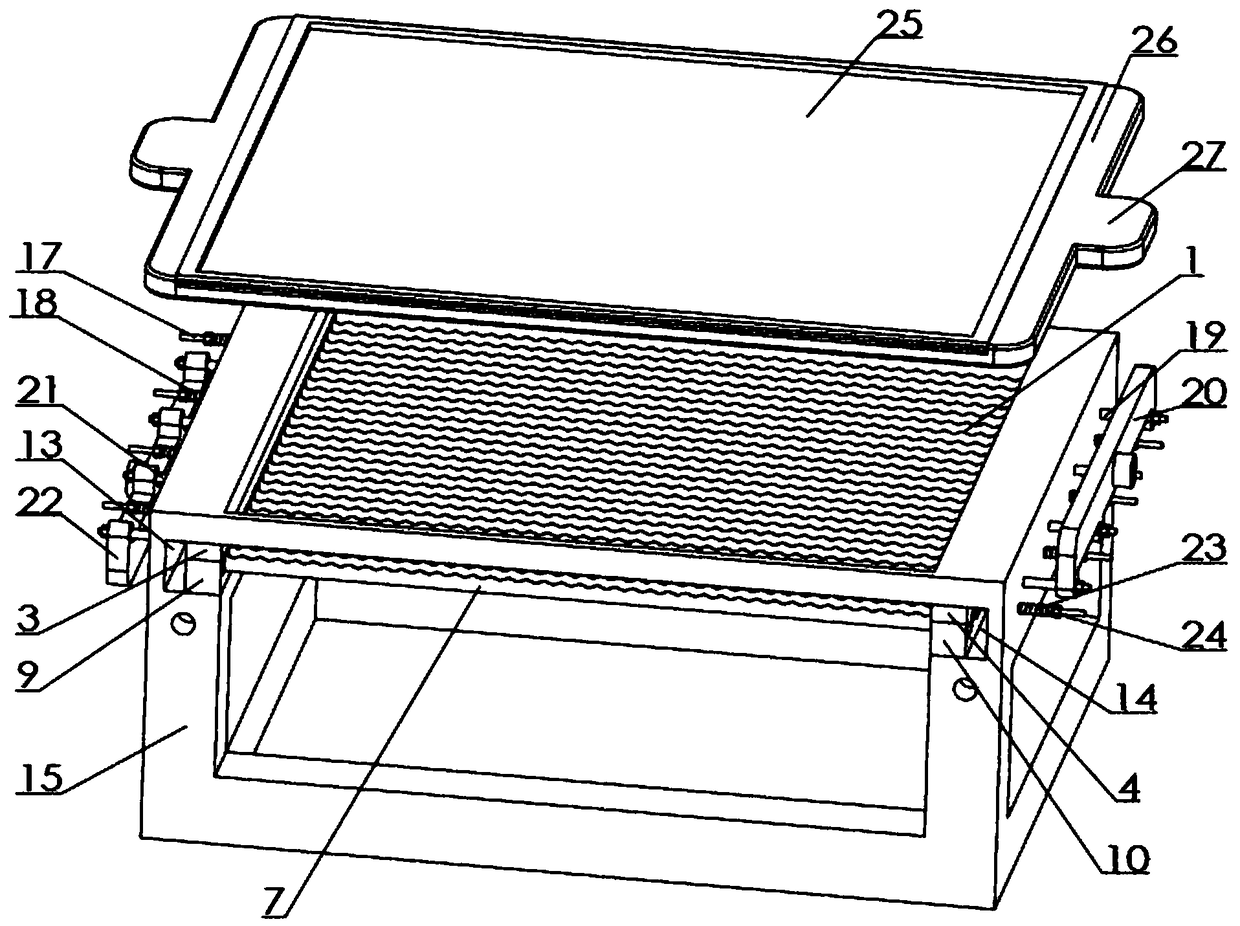

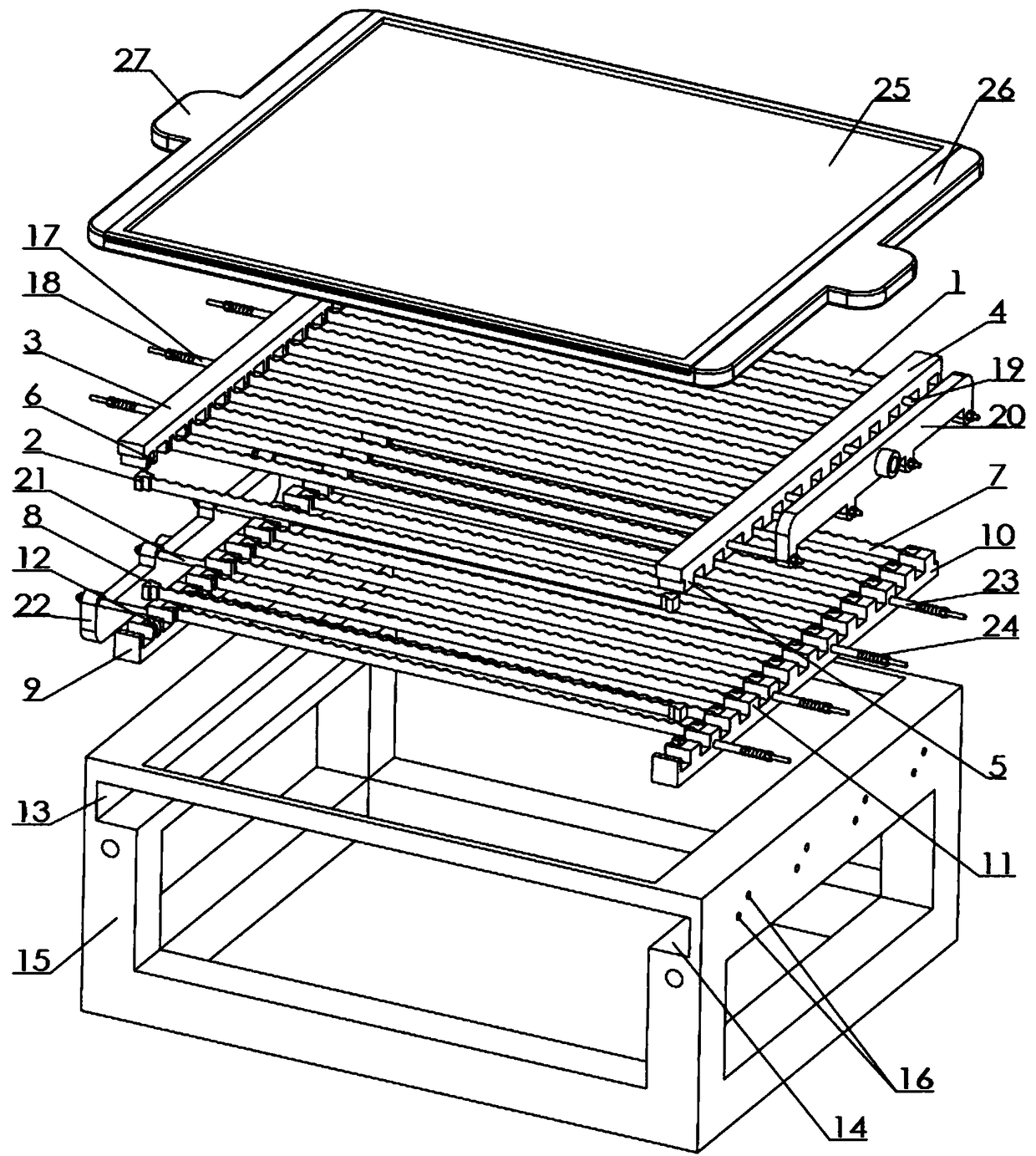

[0014] Examples of the present invention figure 1 , 2 As shown, the reciprocating kiwifruit slicing device is provided with a first knife assembly and a second knife assembly;

[0015] The first knife assembly is provided with a first group of blades 1 with blades facing upwards, and the first block 2 is connected to both ends of the first group of blades, and the two ends of the first group of blades are respectively provided with a left upper slide bar 3 and a right upper slide bar 4, There are one-to-down upper slider protrusions 5 equidistantly distributed below the left and right upper sliders, and the upper slider protrusions are provided with a first card slot 6 adapted to the first block, and the first group of blades are two The first card block at the end corresponds to the first card slot one by one and is embedded in the first card slot, and the outer surfaces of the left and right upper sliders are respectively provided with threaded holes;

[0016] The second k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com