A pressurized press and a wire terminal crimping machine using the press

A technology of punching machine and frame, which is applied in the field of pressurized punching machine and the crimping machine applying the punching machine, can solve the problems such as being unsuitable for use in air-conditioned workshops and dust-free workshops, inconvenient in the process of equipment transportation and installation, and unable to realize pressure-holding delay. , to achieve the effect of convenient installation and transportation, reasonable stress and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

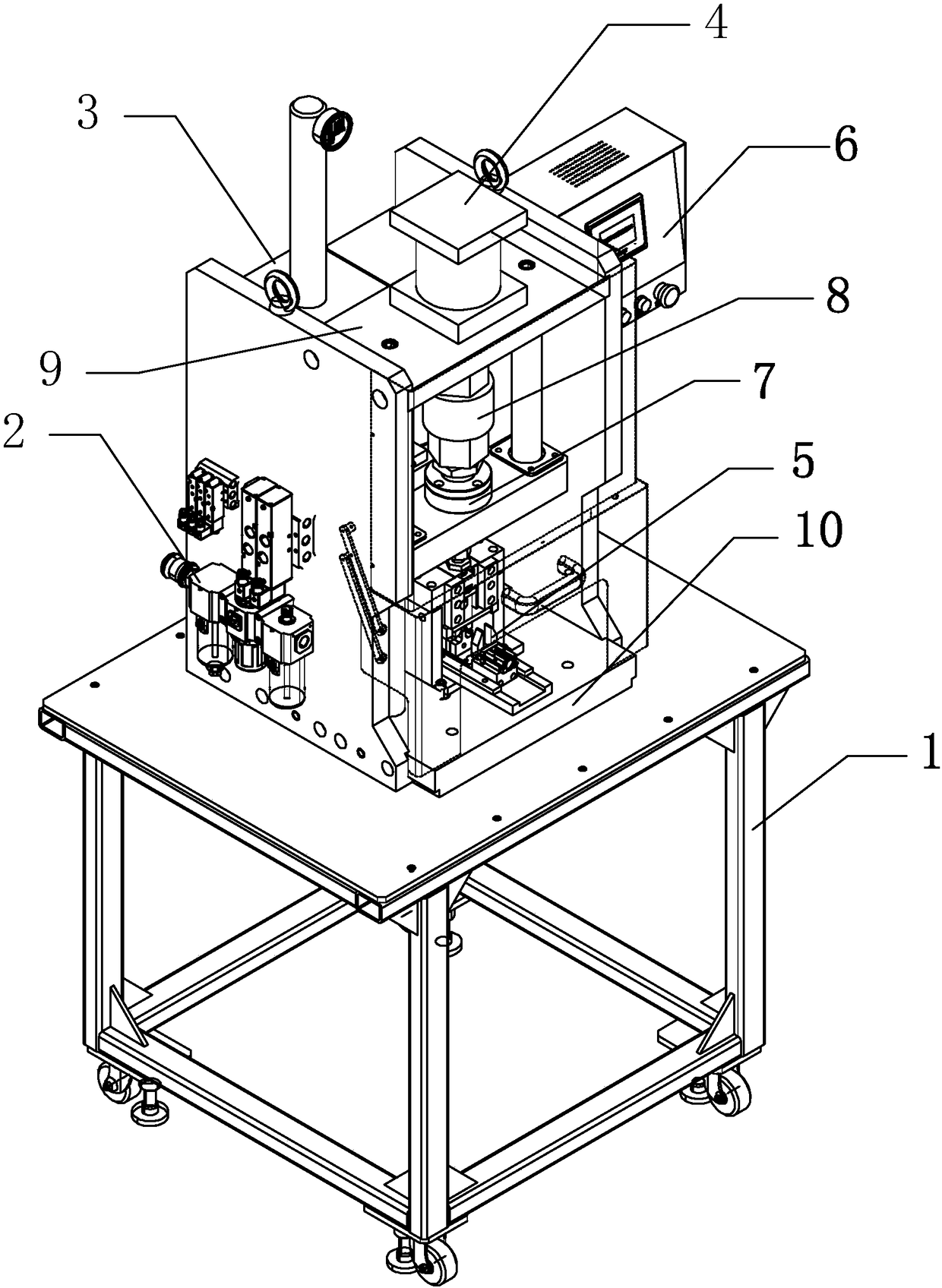

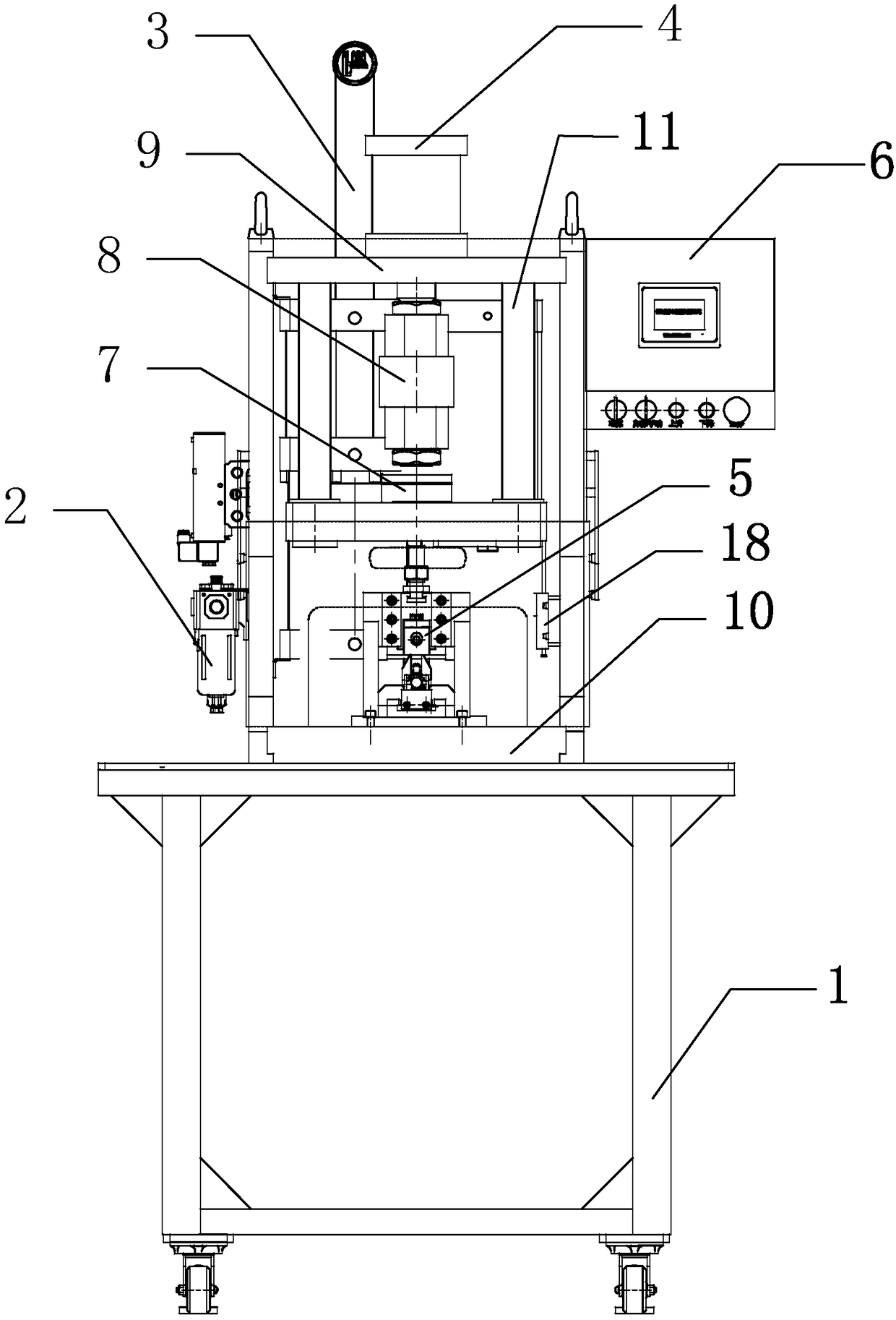

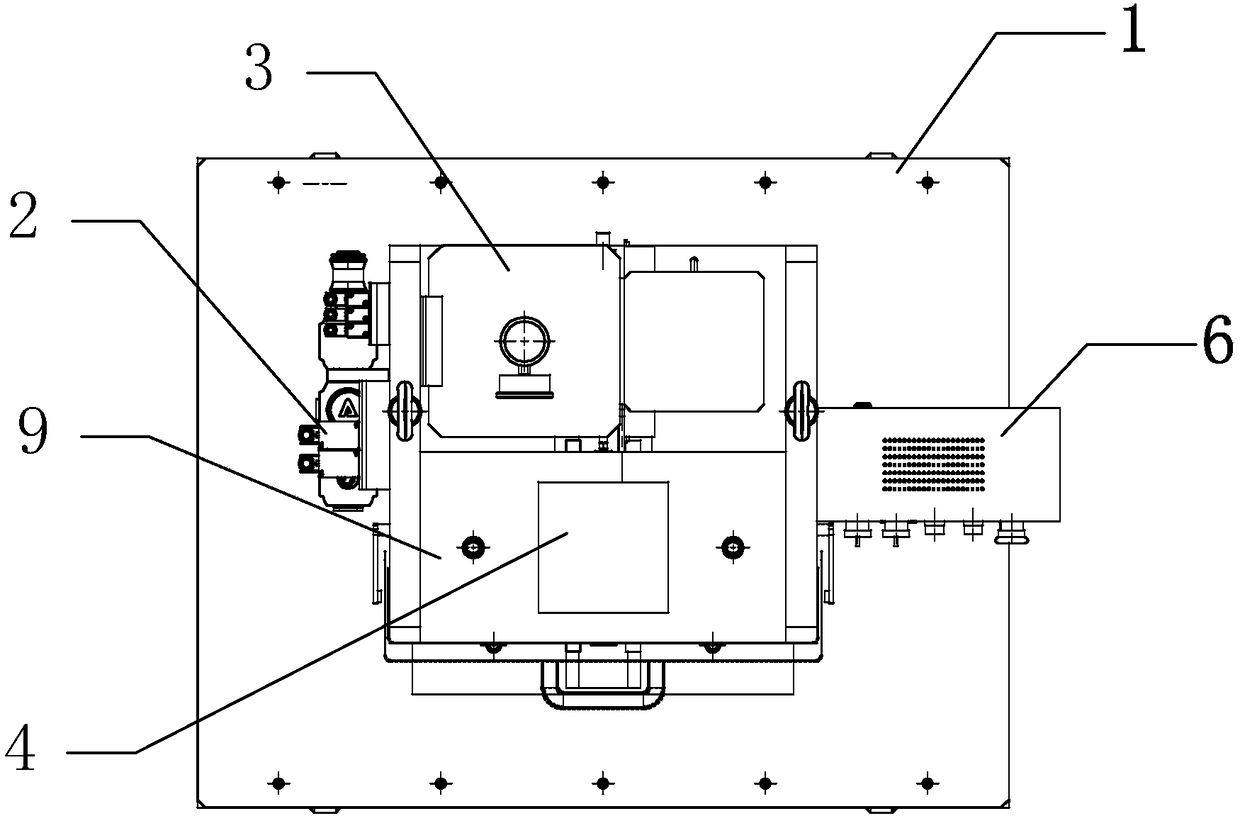

[0038] Such as Figure 1-7 , a pressurized press, including a frame 1, an air source processing module 2, an air-liquid conversion cylinder 3, a hydraulic cylinder 4, and a mold 5; the air source processing module 2 is connected to an external general air pressure, and the air source processing module 2 It is connected to the gas-liquid conversion cylinder 3, which is also called a booster cylinder, and is connected to the hydraulic cylinder 4. There is no punch press in this gas-hydraulic pressurization mode on the market now.

[0039] The frame 1 includes two side plates, a bottom plate 10 and a hydraulic cylinder subassembly 9 . The side plates are integrated metal plates, and the two side plates are respectively provided with fixing grooves for fixing the bottom plate 10 and the hydraulic cylinder subassembly 9, and the fixing grooves can also be set as step grooves, and the fixing grooves are respectively Set on the upper and lower ends of each side plate, the correspon...

Embodiment 2

[0063] A wire terminal crimping machine using the above pressurized punch press, the mold 5 used is a wire terminal crimping die. A slide rail can be provided under the crimping die, and the automatic feeding and returning can be realized through the cylinder.

[0064] The punching machine exerts pressure on the material to make it plastically deform, so as to obtain the required shape and precision. Therefore, a set of molds 5 must be matched, divided into an upper mold and a lower mold, and the material is placed between them, and the machine applies pressure to deform it. , The reaction force caused by the force applied to the material during processing is absorbed by the punch machine body. The mold 5 of the punch press is matched with a corresponding automatic feeding device, which has the functions of feeding error detection, pre-cutting, and pre-breaking, and can fully realize automatic production with low cost and high efficiency.

[0065] This wire terminal crimping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com