Low-energy consumption self-power generation wheel hub cover

A technology of self-generating and hubcaps, applied in the direction of hubcaps, wheels, transportation and packaging, etc., can solve the problems of unrecognizable, unrecognizable, and difficult identification of hubcaps, achieve good chemical stability, improve service life, and performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

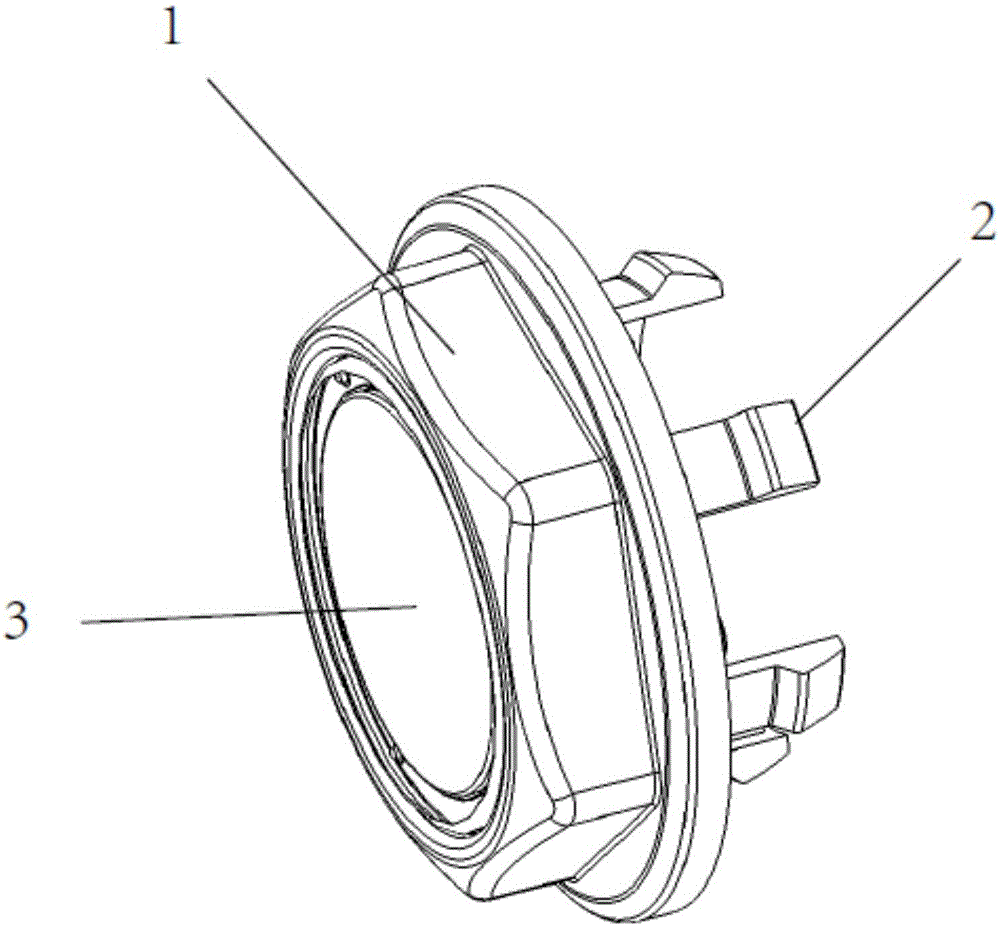

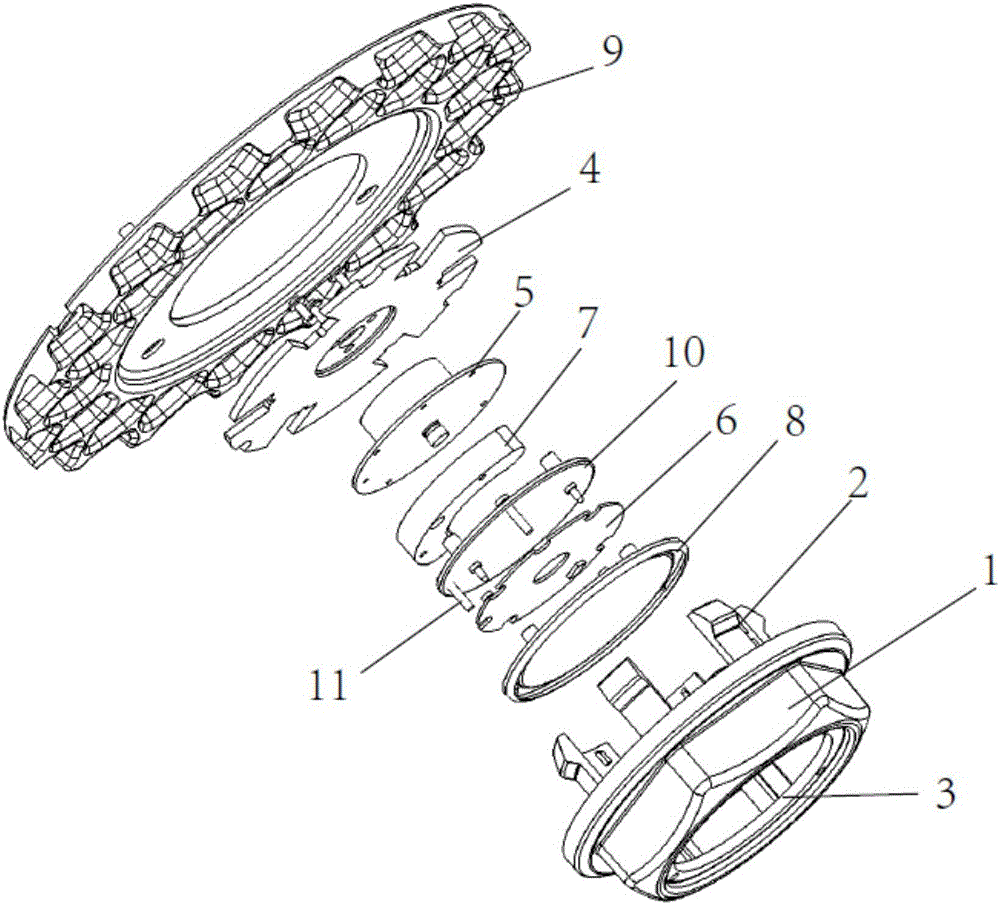

[0023] refer to Figure 1 to Figure 4 As shown, a low-energy self-generating hub cover includes a cover body 1, the cover body is uniformly provided with hub clip corners 2, which can clamp the cover body on the hub, and the middle part of the cover body surface is provided with a transparent window 3, which is convenient The light inside the cover body shines through. A bottom plate 4 is arranged inside the cover body. The bottom plate and the cover body rotate synchronously. The bottom plate and the inside of the cover body form an accommodating space. The machine shaft is fixedly connected with the luminous board 6, the generator rotates to generate electricity and supplies power to the luminous board, a counterweight 7 is arranged on the luminous board, and a LOGO board 8 is fixedly arranged on the surface of the luminous board. The bottom plate has the function of supporting all the components in the accommodation space. The bottom plate and the cover body are fixedly con...

Embodiment 2

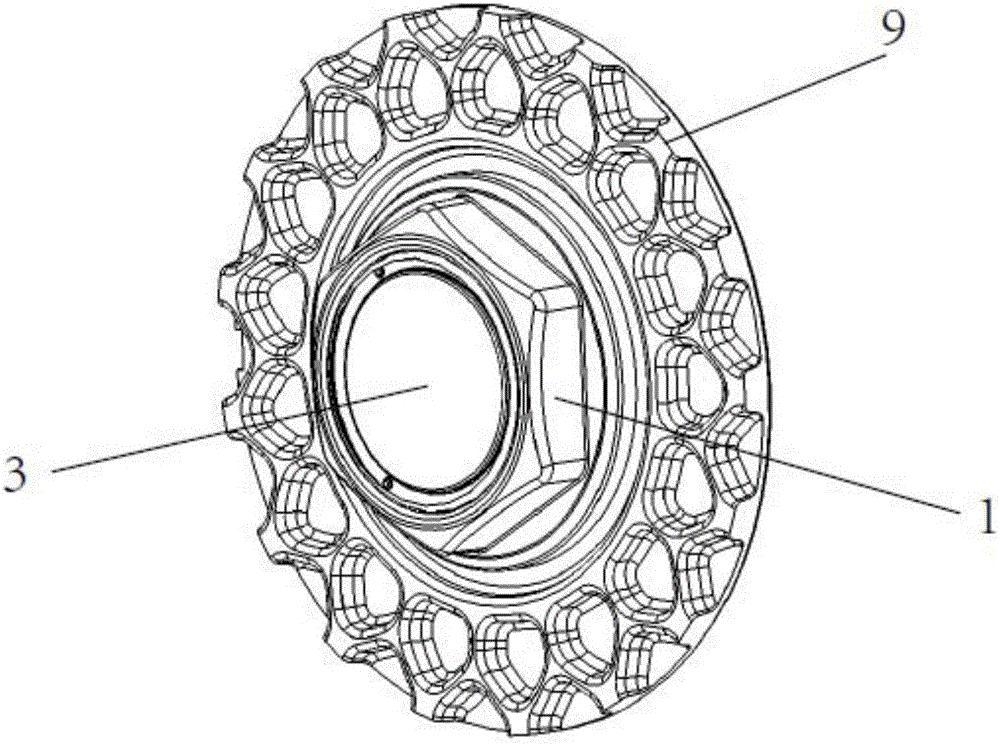

[0030] The difference between the second embodiment and the first embodiment is that it also includes a bottom cover 9, the bottom cover is arranged at the bottom of the cover body, the hub card angle is set through the bottom cover, and the axial distance of the accommodating space can be limited by the design of the bottom cover. In this way, the function of fixing the bottom plate is realized, the operation is simple and reliable, and it can cover the wheel hub in a large area to meet different needs.

[0031] In parts by weight, the formula of the lid body includes the following components:

[0032]

Embodiment 3

[0034] The difference between Embodiment 3 and Embodiment 1 is that, in parts by weight, the formula of the lid body includes the following components:

[0035]

[0036] The cover body produced by the material formula in the above three embodiments has strong chemical corrosion resistance and good chemical stability, which is beneficial to use on different driving roads, is not afraid of sewage erosion, improves service life, has great development prospects, and can It does not change color under direct sunlight for a long time, does not crack, has stable quality, is cheap, has a high yield rate, and has excellent performance. The lid body is put into a high and low temperature test box for testing, and the temperature is adjusted to 70 degrees for 8 hours. The result It shows that the cover body of the present invention has no sign of melting in appearance after 8 hours, and there is no change in size. In addition, the cover body of the present invention is immersed in sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com