Plastic building template and producing method thereof

A technology of building formwork and production method, which is applied in the direction of building, building structure, formwork/formwork components, etc. The effect of high volume, high static bending strength, high screw holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

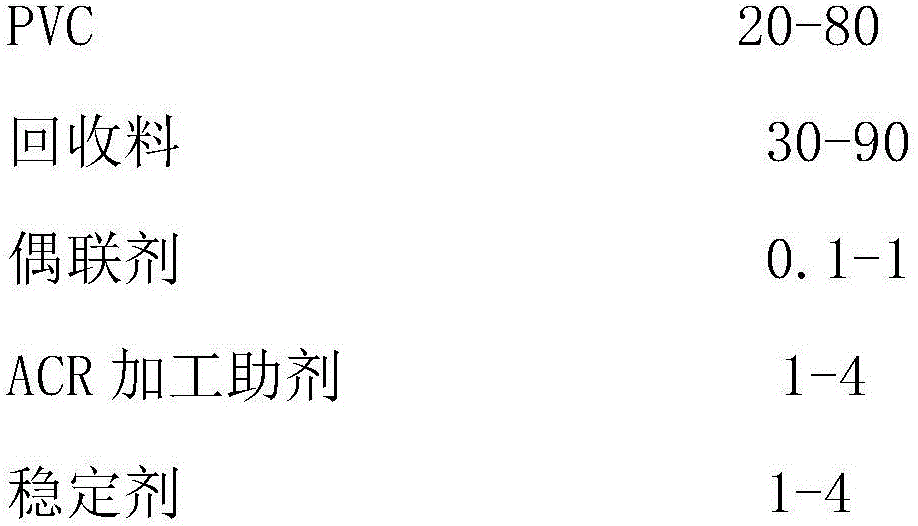

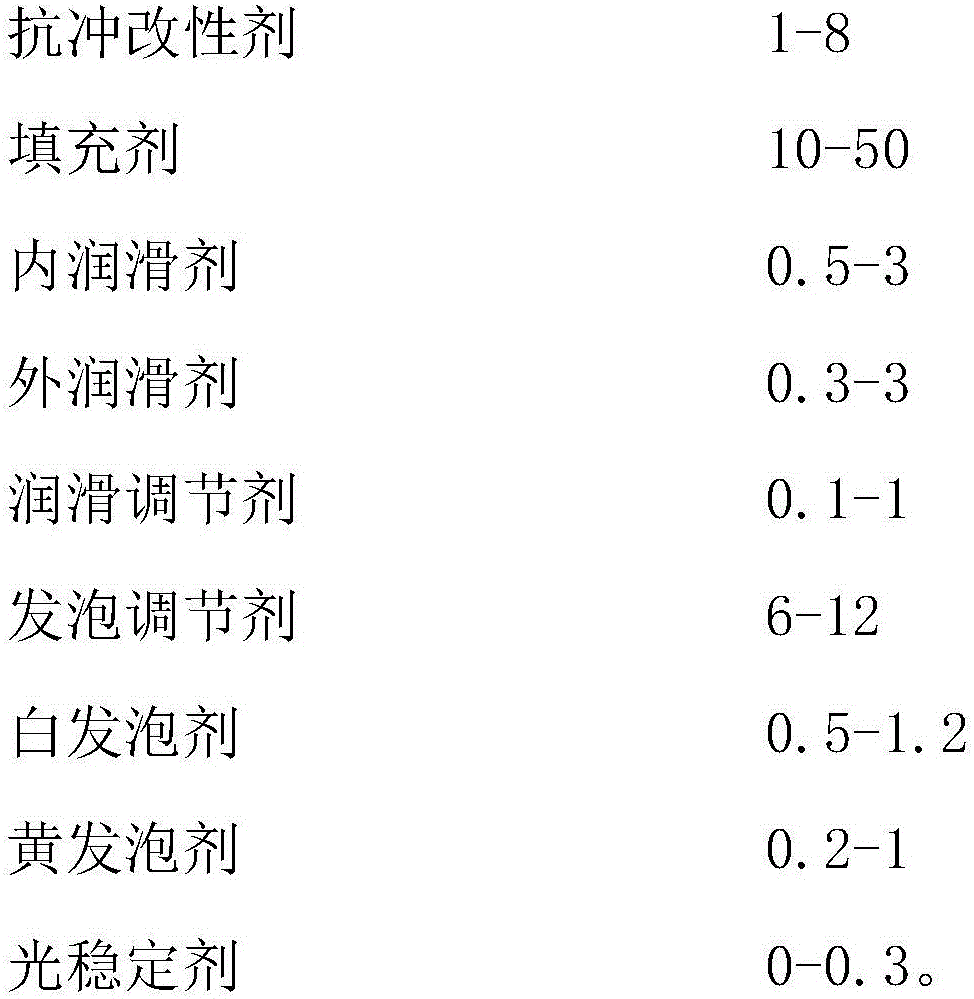

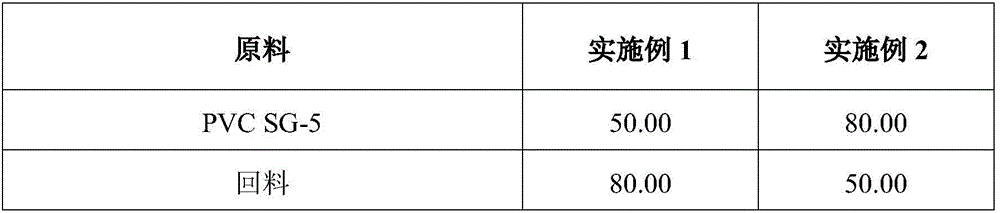

[0069] A kind of PVC building formwork, its formula is as follows table 1.

[0070] A production method of PVC building formwork, comprising the following steps:

[0071] 1. Through the automatic batching system, the required materials are automatically measured according to a certain formula ratio, and then put into the thermal mixer for mixing. During the thermal mixing process, the moisture in the mixture is fully removed by thermal mixing, and the materials are in the thermal mixer. Mix for 400-500 seconds, discharge into the cold mixer after reaching the process temperature of 110°C, cold mix for 300-400 seconds, remove foreign matter at 45°C by Roots blower and vibrating screen, enter the storage tank, and homogenize for 24 hours.

[0072] 2. After the powder mixture enters the extruder from the hopper on the extrusion line, with the continuous movement forward and the temperature change during the extrusion process, the material slowly changes from solid to viscous flui...

Embodiment 2

[0074] A kind of plastic building formwork, its formula is as follows table 1.

[0075] A production method of a plastic building formwork, the steps are the same as in Example 1, and the parameters of the extruder are controlled in the following table 2.

[0076] Table 1:

[0077]

[0078]

[0079] Table 2:

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com