Micro-nano powder material and preparation method thereof

A powder material, micro-nano technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve problems such as contact, powder darkening, coating corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

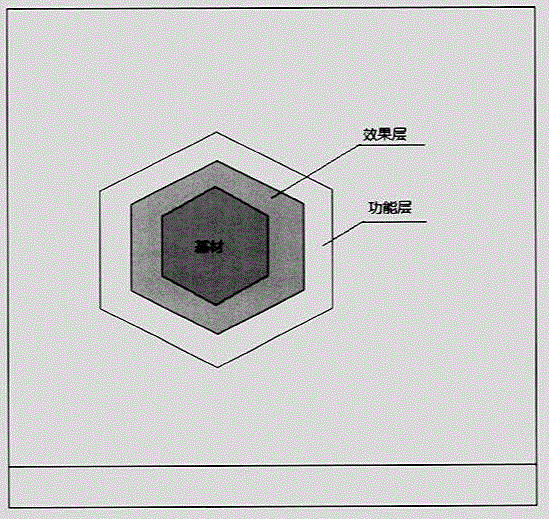

Image

Examples

Embodiment 1

[0024] Quartz sand with a particle size of 20-40 microns and an aspect ratio of 0.5-0.8 is used as a polyhedral pigment substrate after being washed and dried with an organic solvent. The surface of the quartz sand is coated with a thickness of 20-30nm by vacuum evaporation. aluminum layer. DC magnetron sputtering is adopted, aluminum is used as the target material, oxygen is passed through, and reactive sputtering is carried out, and an aluminum oxide coating with a thickness of 10nm is coated on the outside of the aluminum coating to prevent the aluminum coating from being oxidized and blackened.

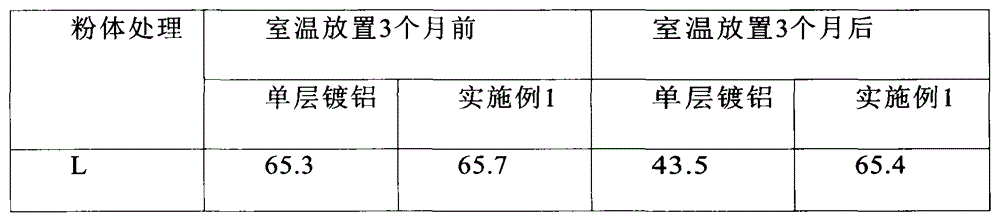

[0025] The composite coating silver polyhedron pigment and the single-layer aluminum coating polyhedron pigment were placed together in the same room temperature air environment, and after three months, the L values of the two polyhedron pigments were measured. The measurement results are shown in Table 1:

[0026]

[0027] From the measurement results, the composite coating...

Embodiment 2

[0029] The glass powder with a particle size of 20-40 microns and an aspect ratio of 0.5-0.8 is coated with an aluminum layer with a thickness of 15-30nm on the surface of the glass powder by magnetron sputtering technology, and the outer side of the aluminum layer is coated A layer of silver plating with a thickness of about 10nm is attached. The L value of the silver polyhedral pigment was measured before and after silver plating, and the results showed that the addition of silver plating increased the L value of the powder from 63 to 72, which can effectively improve the brightness of the powder.

Embodiment 3

[0031] Glass powder with a thickness of 30-50 microns and an aspect ratio of 0.6-0.8 is coated with a layer of aluminum coating with a thickness of 15-30nm on the surface of the glass powder by magnetron sputtering technology, and a layer of aluminum coating is coated on the outside of the aluminum layer. Titanium dioxide coating with a thickness of approximately 192nm. A polyhedral metallic pigment with iridescent red interference was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com