Manufacture method and manufacture device for plastic surface-enhancing Raman chip

A technology for surface-enhanced Raman and preparation devices, which is used in measurement devices, Raman scattering, analysis of materials, etc., can solve the problems of complex chemical process, long time, and limit the batch preparation of surface-enhanced chips, and achieves good repeatability and operation. Simple, easy-to-build effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

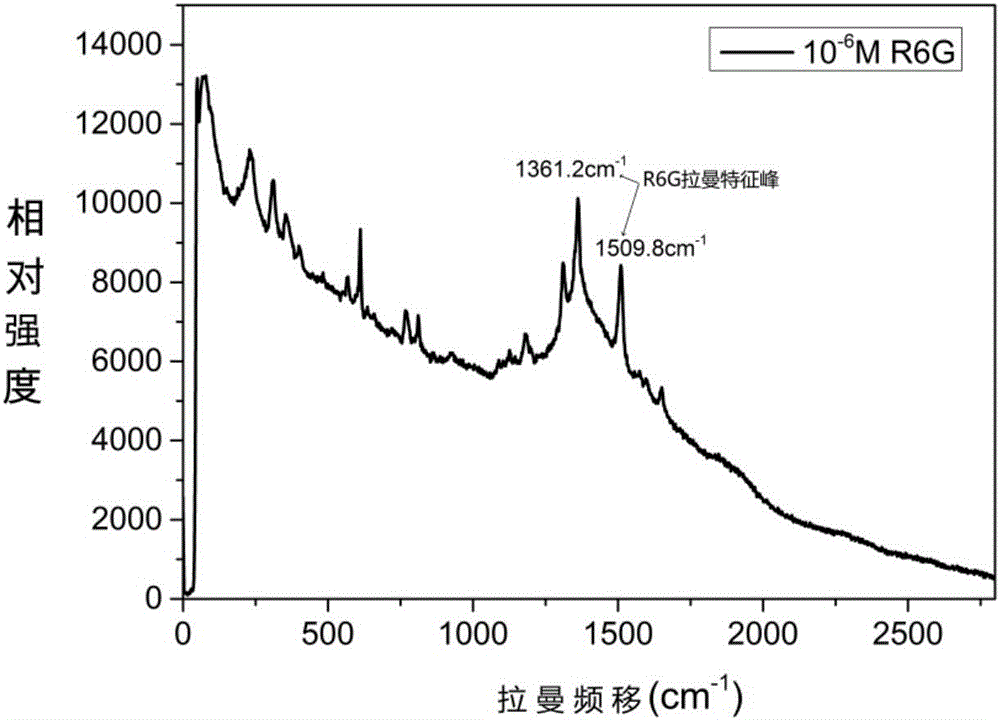

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

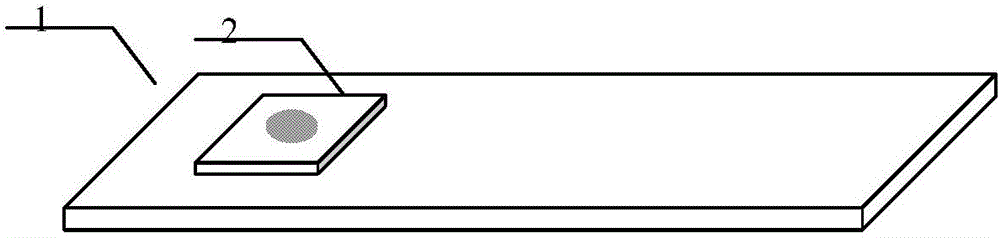

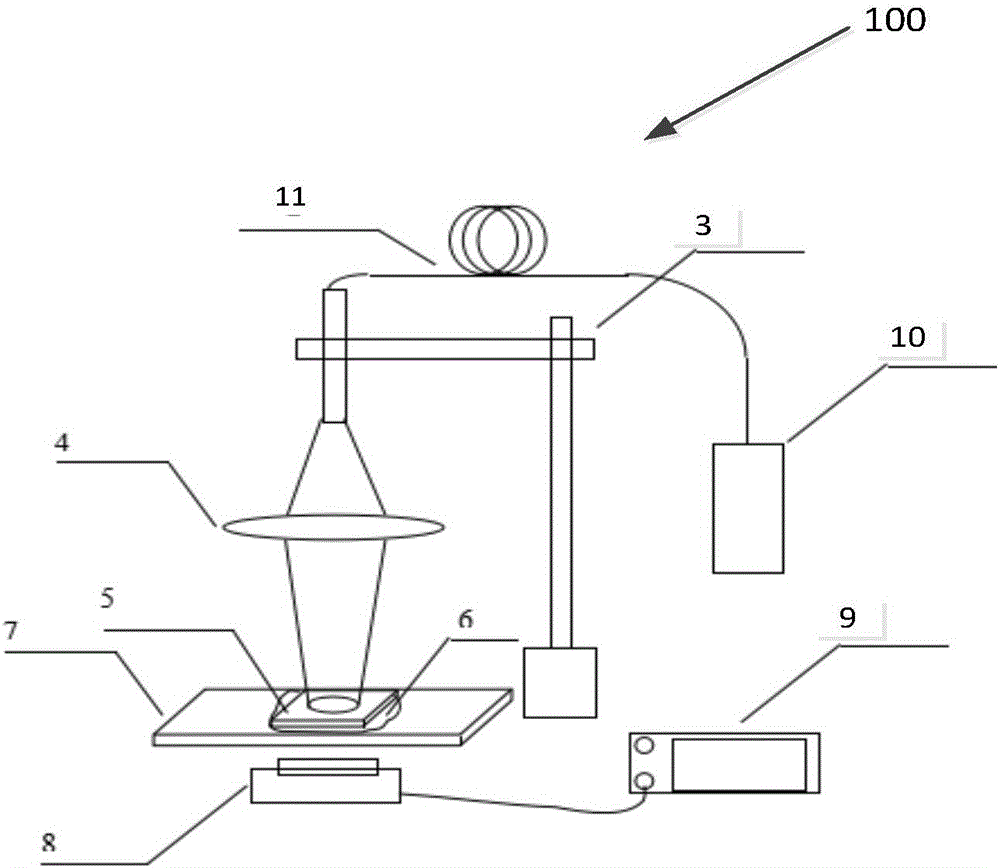

[0035] The embodiment of the present invention provides a method for preparing a plastic surface enhanced Raman chip, comprising the following steps:

[0036] Generate excitation light and irradiate it on the plastic substrate;

[0037] Dropping the reducing solution onto the surface of the plastic substrate to deposit a layer of metal nanoparticles on the surface of the plastic substrate, and controlling the excitation light power and / or illumination time to make the metal nanoparticles reach the required size;

[0038] Remove the reducing solution on the surface of the plastic substrate, and fix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap