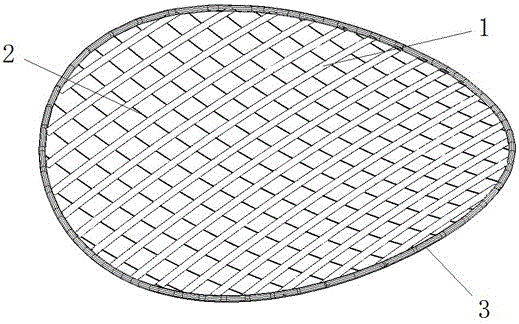

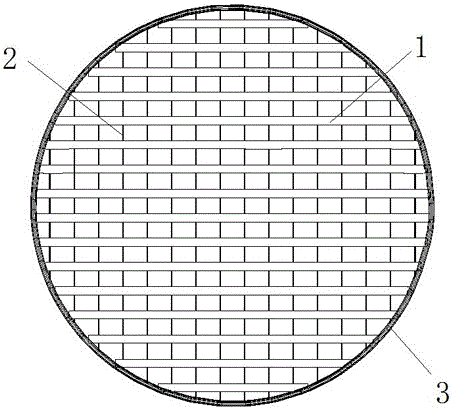

Steel sheet strip and cable net structure

A technology of cable net structure and steel strip, which is applied in special structures, building components, building structures, etc., can solve the problems of complex structure and high cost, and achieve the effect of simple structure, less steel consumption and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

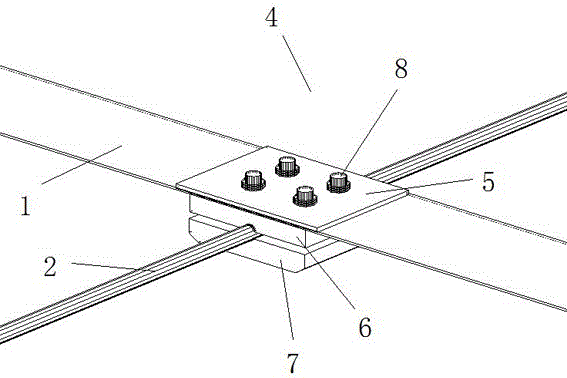

[0020] Implement the basic steps of strip steel plate belt cable net structure design and construction of the present invention

[0021] 1) Steel plate belt cable net structure design

[0022] (1) First select the rigid roofing material, and preliminarily determine the basic size of the cable network grid, the geometric topology relationship, and the support constraints according to its spanning capacity;

[0023] (2) Carry out structural form-finding and force-finding analysis, and preliminarily determine the structural configuration and prestress according to the allowable deformation values of rigid roof materials and steel plate cable nets;

[0024] (3) Determine the materials and specifications of steel strips and load-bearing cables according to the initial prestress value;

[0025] (4) Carry out the analysis of the limit state of bearing capacity and normal service limit state and other necessary analysis;

[0026] (5) According to the analysis results, adjust and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com