Hydraulic pumping unit and method for replacing oil cylinder piston seals without motor

A technology of piston seals and pumping units, which is applied in the field of hydraulic pumping units, can solve problems such as inconvenience, and achieve the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

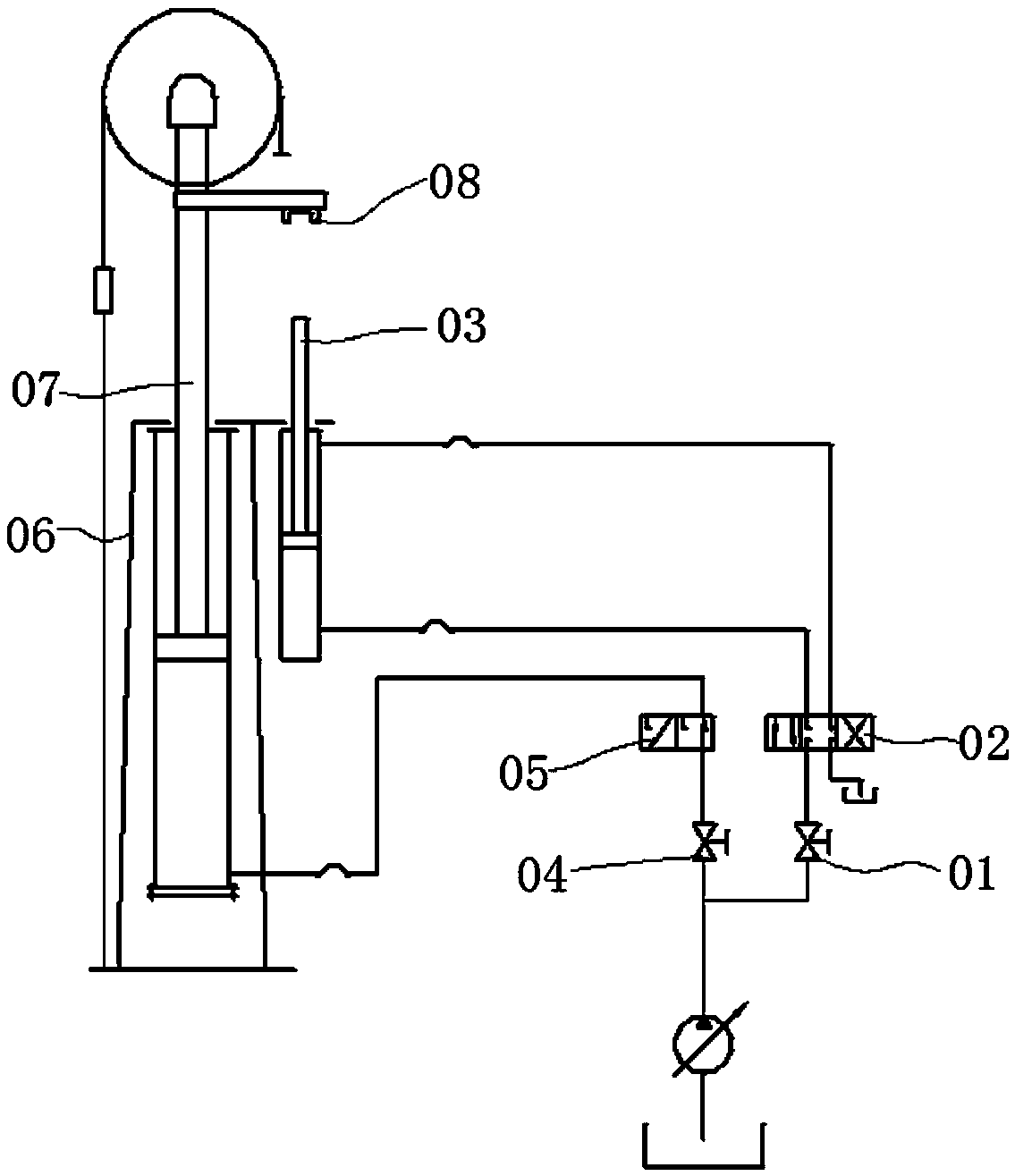

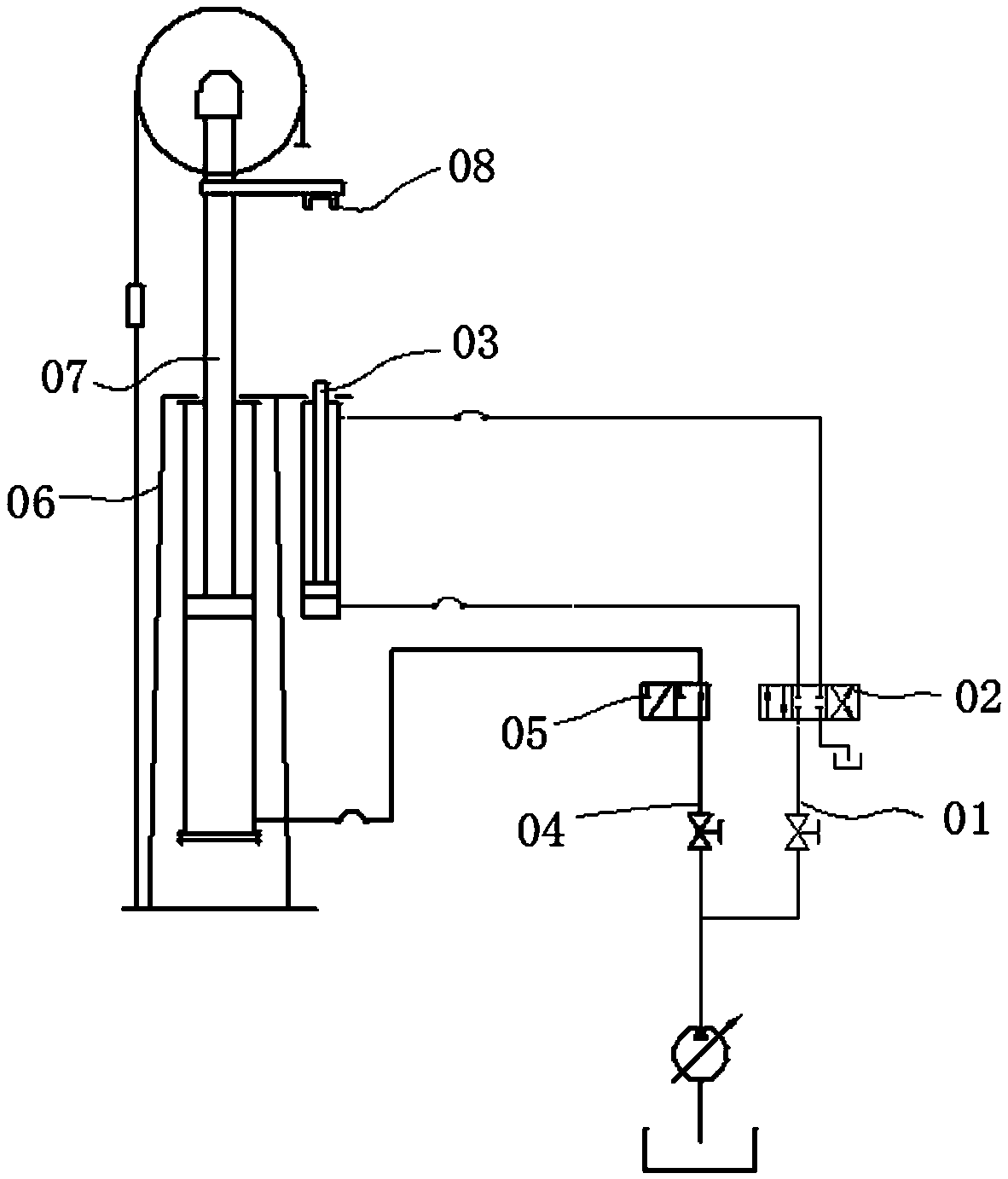

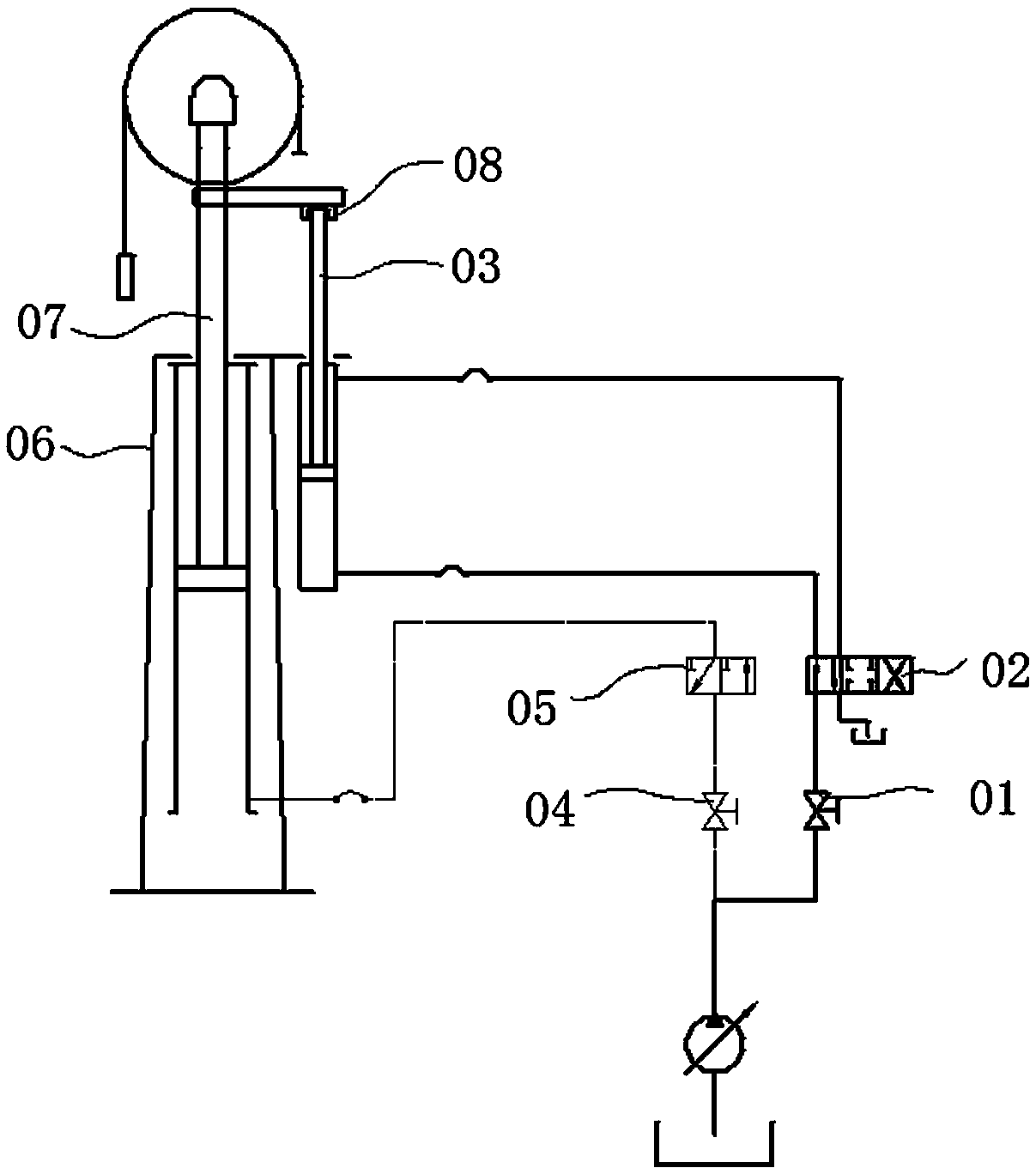

[0028] Below in conjunction with accompanying drawing, the hydraulic pumping unit of the present invention does not change oil cylinder piston seal is carried out in detail. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but to illustrate the essence of the technical solution of the present invention.

[0029] According to the hydraulic pumping unit of the present invention, its technical proposal is: a hydraulic pumping unit without engine replacement of cylinder piston seals. The hydraulic pumping unit includes a hydraulic station, a main hydraulic cylinder, a frame, connectors and a supporting hydraulic cylinder. The main hydraulic cylinder of the hydraulic pumping unit is installed on the frame, and the piston rod is connected with the wellhead polished rod through the connecting piece with the direction of the piston cylinder facing upwards. The supporting hydraulic cylinder is mounted on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com