Eccentric disc insertion tapered pipe fitting and manufacture method thereof

A manufacturing method and technology for reducing pipe, which are applied in the direction of pipes/pipe joints/fittings, manufacturing tools, passing elements, etc., can solve the problems of low efficiency, inability to prepare eccentric disk inserting reducing pipe fittings, time-consuming and labor-intensive, etc. High efficiency, convenient and unified excavation, good economical and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

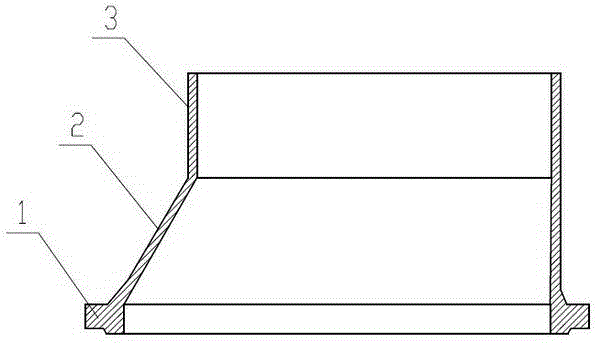

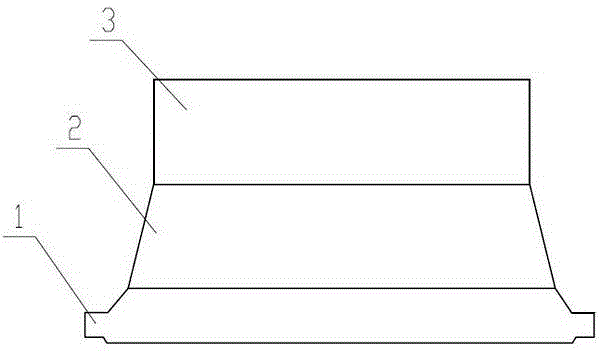

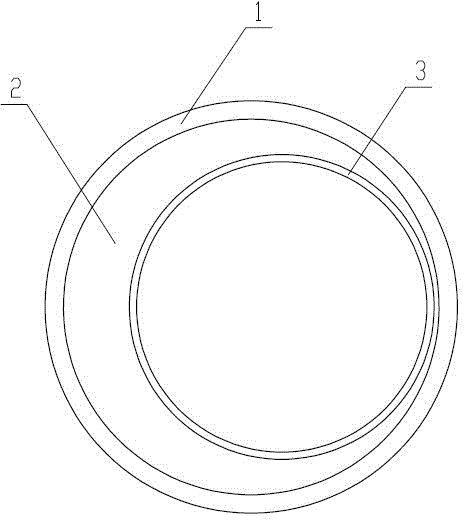

[0031] To make DN 600*500 PN 16 eccentric disc tapered pipe fittings, choose DN 600 PN 16 flanges, the socket is DN500, the length is 110mm, the overall height of the pipe fittings is 600mm, the wall thickness of the flange end pipe fittings is 13.2mm, the socket The wall thickness of the pipe fittings is 12mm. The specific production steps are as follows:

[0032] (1) Make the lower box: Put the mold corresponding to the flange chassis 1 into the sand box and fix it, fill it with sand and shape it, then paint it and dry it to make the lower box;

[0033] (2) To make sand cores for eccentric tapered tubes: Firstly, according to the shape of the sand cores corresponding to the eccentric tapered tubes 2 to be manufactured, splice and weld 3-5 mm thick steel plates to make eccentric tapered core box molds. Then weld the core iron, put the finished core iron into the eccentric tapered core box mold, fill sand to shape, and then take the formed eccentric tapered tube body sand cor...

Embodiment 2

[0045] To make DN 1200*1000 PN 10 eccentric disc tapered pipe fittings, choose DN 1200 PN 10 flanges, the socket is DN1000, the length is 130mm, the overall height of the pipe fittings is 790mm, the wall thickness of the flange end pipe fittings is 20.4mm, the socket section The pipe wall thickness is 18mm. Concrete manufacturing steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com