Axial thrust bearing structure of centrifugal compressor of high-speed motor

A centrifugal compressor, axial thrust bearing technology, applied in machines/engines, components of pumping devices for elastic fluids, mechanical equipment, etc. Compact, increased rotation speed, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

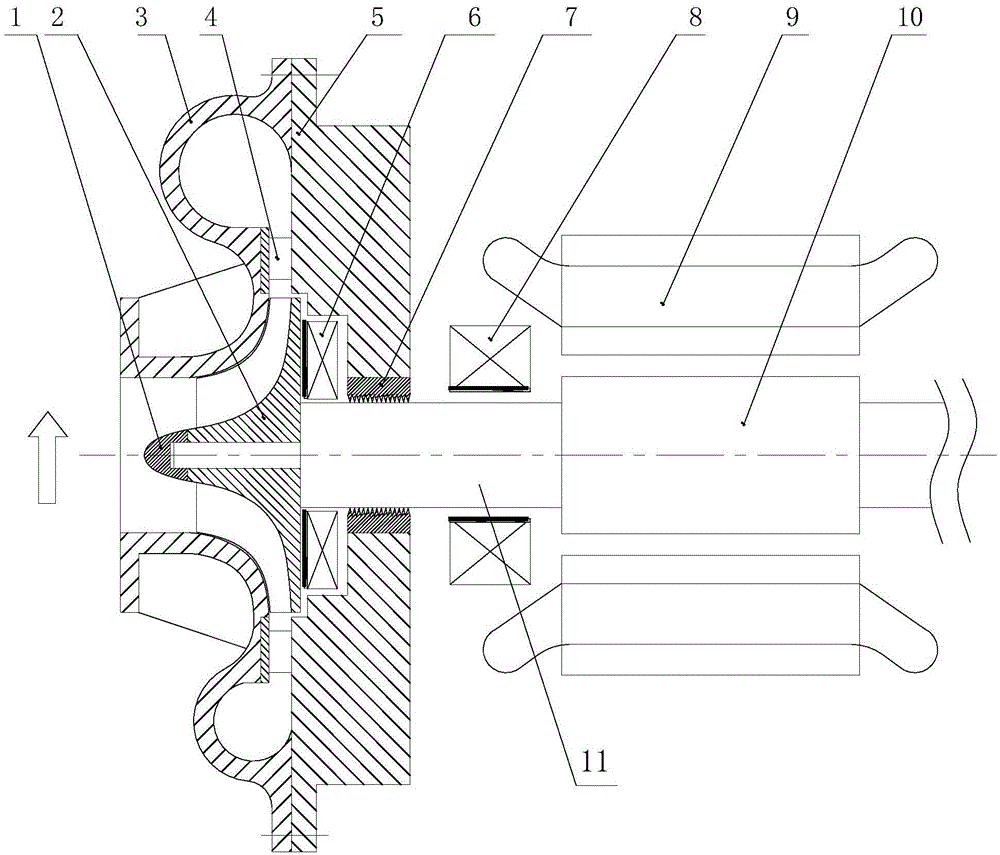

[0030] Embodiment 1, an axial thrust bearing structure of a centrifugal compressor with a high-speed motor, in which an axial thrust bearing 6 is arranged against the back of the impeller 2 . Such an arrangement structure is particularly compact, and there is no need to fix a ring of steel plates on the rotating shaft 11, and then two axial thrust bearings are clamped on both sides of the steel plate ring to shorten the length of the rotating shaft 11.

Embodiment 2

[0031] In Embodiment 2, the axial thrust bearing 6 is arranged against the back of the impeller 2, and the air seal 7 is connected with the axial thrust bearing 6 to form an integral structure. Such configuration is also an obviously compact configuration, fixation and connection structure compared with the prior art, and also serves the purpose of shortening the length of the rotating shaft 11 and the rotor.

Embodiment 3

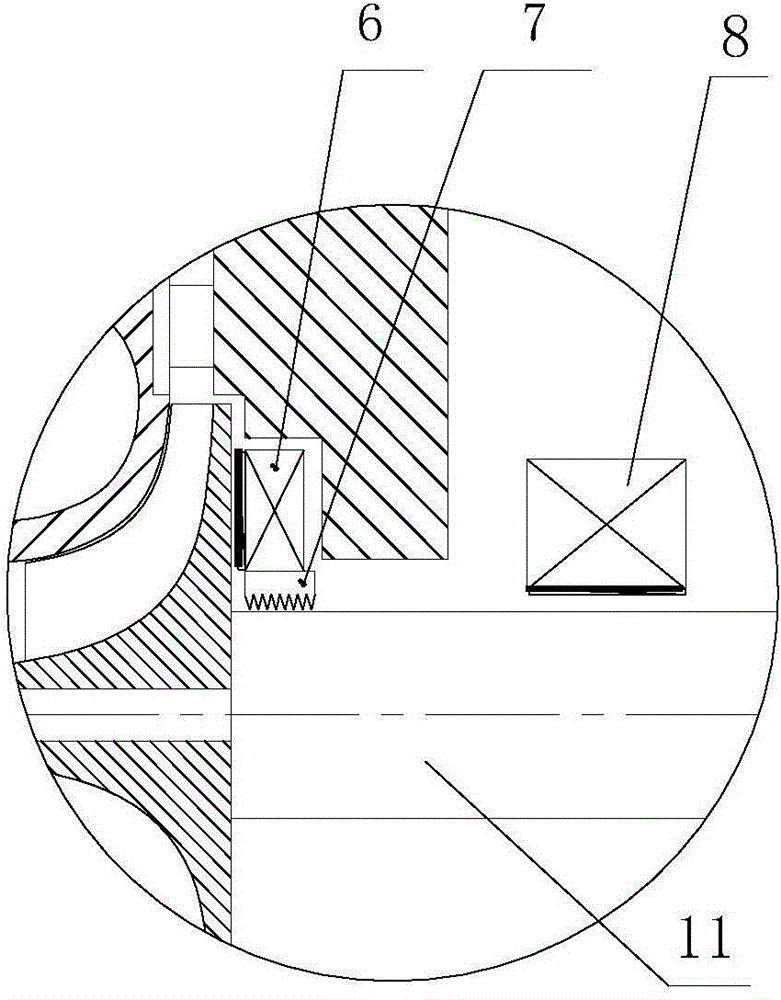

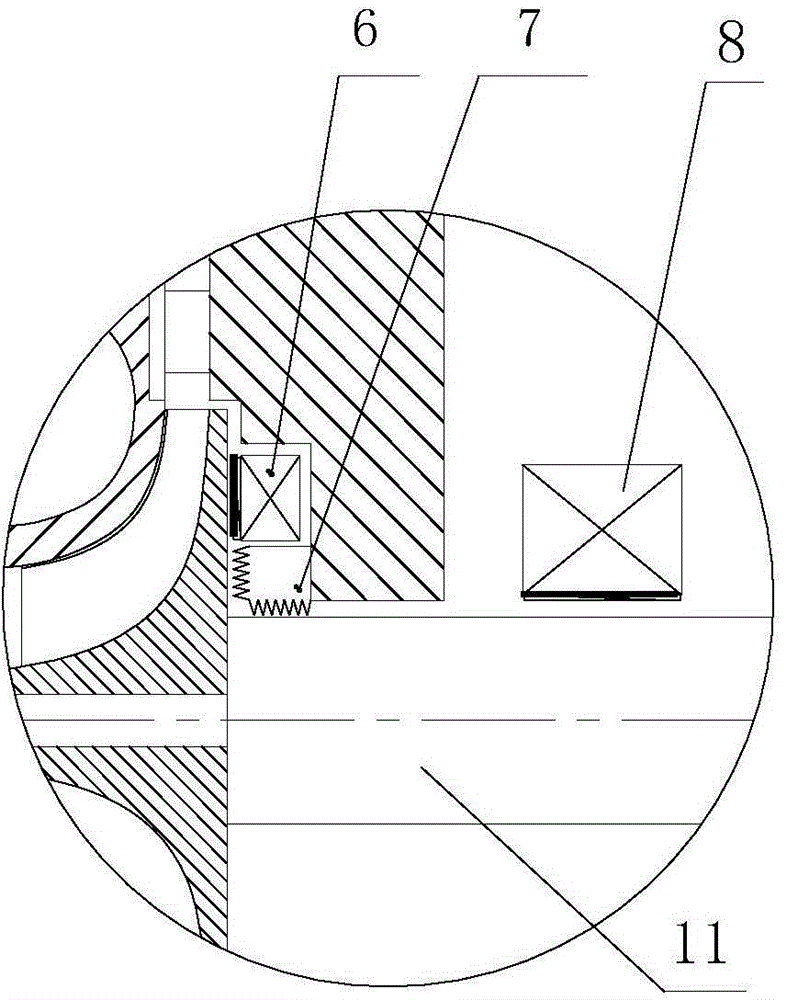

[0032] Embodiment 3, an axial thrust bearing structure of a centrifugal compressor with a high-speed motor, the compressor impeller 2 is arranged in the volute 3, the volute 3 is fixed on the casing 5 of the compressor, and the rotating shaft 11 of the impeller 2 is fixed Stretch into the central part of the housing 5:

[0033] Axial thrust bearing 6 is arranged against the back of impeller 2, and a section of groove is opened on the corresponding casing 5, and the rear part of the groove is a support section; the inner ring of the support section is fixed with air seal 7, and the sealing surface of air seal 7 is Contact and seal with the rotating shaft 11. The axial thrust bearing 6 of this structure can withstand the axial pressure of the impeller, and the rear support section relies on and supports it. At the same time, using the space in the inner ring of the support section, a fixed air seal 7 is arranged on the inner ring to contact and seal with the rotating shaft 11. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com